Metal stamping is a highly versatile manufacturing process that has become increasingly important in various industries throughout 2023. As businesses strive for efficiency and cost-effectiveness, understanding the benefits of metal stamping is crucial for making informed production decisions. This process entails shaping and cutting metal sheets to create precise parts and components, which are essential in sectors ranging from automotive to electronics. By leveraging metal stamping techniques, manufacturers can achieve significant advantages that can improve their overall operations.

One of the standout features of metal stamping lies in its ability to produce large quantities of parts with exceptional consistency and accuracy. This not only minimizes waste but also reduces production time, allowing companies to meet tight deadlines and customer demands more effectively. Furthermore, metal stamping can accommodate a variety of materials, making it a flexible solution for diverse applications. As we explore the top 10 benefits of metal stamping, it becomes evident that this process is not just about creating components but also about enhancing innovation and sustainability in manufacturing practices.

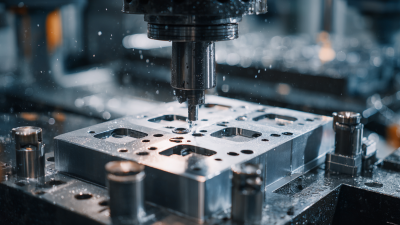

Metal stamping has become an essential process in modern manufacturing due to its numerous advantages that enhance efficiency and quality. One key benefit is the precision it offers. Utilizing advanced technology and high-quality dies, metal stamping can produce complex parts with tight tolerances. This level of accuracy not only minimizes waste but also reduces the need for extensive post-processing, streamlining production cycles.

In addition to precision, metal stamping also allows for high-volume production at competitive costs. The process can easily be scaled to meet large demands without sacrificing quality, making it an ideal choice for industries that require consistent parts in bulk. Furthermore, metal stamping is versatile and can be applied to various materials, including steel, aluminum, and copper, which increases its applicability across different sectors such as automotive, electronics, and aerospace. These advantages make metal stamping a cornerstone of modern manufacturing, driving innovation and efficiency in various industrial applications.

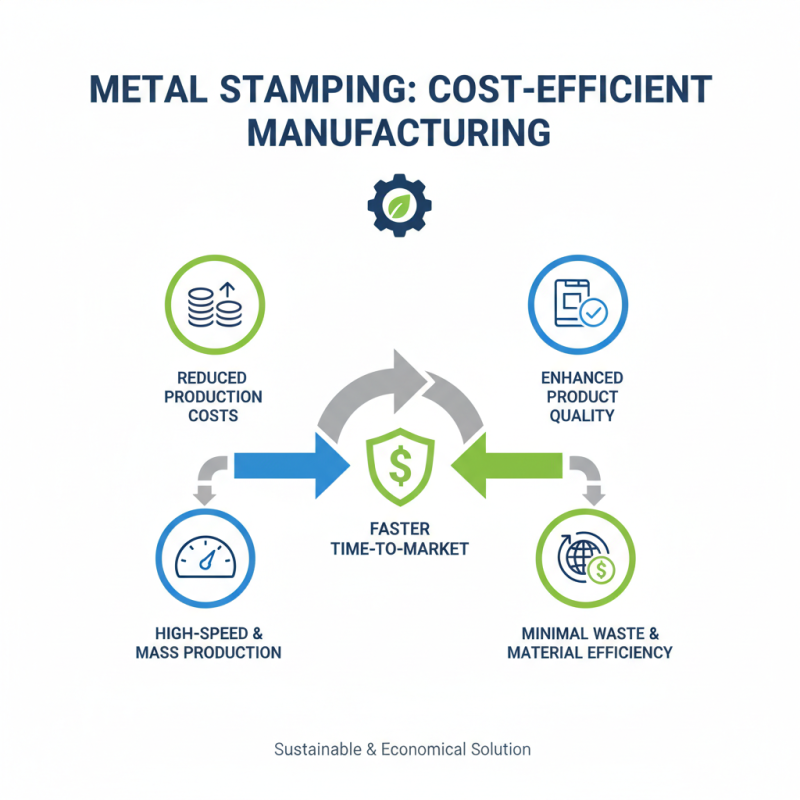

Cost efficiency is a critical consideration for manufacturing processes, and metal stamping stands out as an effective solution. By utilizing metal stamping, companies can achieve significant reductions in production costs while simultaneously enhancing product quality. The high-speed nature of stamping allows for the mass production of components with minimal waste, providing a sustainable approach that maximizes resources. This process minimizes the need for extensive machining, which not only cuts down labor costs but also reduces the time required to bring products to market.

Moreover, metal stamping enables the creation of complex shapes and designs with precision, which reduces the need for secondary processes. This means fewer operational steps are required, leading to lower overall production costs. The ability to work with various materials efficiently further contributes to cost savings, as manufacturers can choose the most economical materials that meet their production requirements. As a result, metal stamping not only offers a cost-effective solution but also supports innovation and flexibility in product development, positioning organizations to better respond to market demands.

Metal stamping techniques offer remarkable design flexibility, allowing manufacturers to create intricate and customized components that meet precise specifications. This flexibility is primarily due to the variety of tools and processes involved in metal stamping, including progressive die stamping, deep drawing, and laser cutting. Each method can be tailored to accommodate complex shapes and varying material thicknesses, which means designers can push the boundaries of creativity without compromising on performance or functionality.

Furthermore, the rapid prototyping capabilities of metal stamping enable quicker adjustments and adaptations during the design phase. Designers can test multiple configurations and quickly iterate on their concepts, thus shortening the development cycle. This agility is especially beneficial in industries where trends evolve rapidly, and companies need to respond to market demands swiftly. By leveraging advanced metal stamping techniques, businesses can not only achieve high-quality results but also foster innovation and differentiate their products in a competitive landscape.

Metal stamping has emerged as a pivotal manufacturing process in 2023, particularly due to its capacity for enhanced production speed and volume. According to a report by the Precision Metalforming Association, the metal stamping industry has seen a growth rate of around 6% annually, with advancements in technology leading to more efficient processes. Modern stamping presses can operate at speeds exceeding 1,000 strokes per minute, allowing manufacturers to produce a higher number of parts in less time compared to traditional methods. This increased efficiency not only accelerates the production timeline but also meets the escalating demand for high-volume components across various industries such as automotive, aerospace, and consumer goods.

Additionally, the optimization of metal stamping methods has significantly contributed to volume scalability. The integration of automation and computer numerical control (CNC) technology into stamping operations permits finer control and greater repeatability in production. A study by the Manufacturing Institute indicates that manufacturers utilizing automated stamping methods have reported increased output by up to 50%, showcasing the significant impact of technology on production capabilities. By streamlining processes and reducing lead times, metal stamping has established itself as a vital solution for businesses aiming to enhance their operational efficiency in a competitive market environment.

Metal stamping is a versatile manufacturing process that finds diverse applications across numerous industries. In the automotive sector, metal stamping is essential for producing components such as body panels, brackets, and chassis parts, which require precision and consistency. Similarly, the electronics industry relies on metal stamping to create intricate parts like connectors and housings that are fundamental to device functionality. This method not only enhances product performance due to its accuracy but also allows for rapid production speeds, enabling manufacturers to meet high demand efficiently.

When considering metal stamping for your projects, it’s crucial to keep some tips in mind. First, collaborate closely with your design team to optimize the design for stamping; this can significantly impact the manufacturing process and the final product quality. Second, ensure material selection is aligned with your application requirements, as different metals can offer varying properties, such as strength and corrosion resistance. Lastly, keep an eye on advancements in technology, as innovations in metal stamping techniques can enhance efficiency and lower production costs while maintaining high-quality standards. By leveraging these insights, industries can maximize the benefits of metal stamping and maintain a competitive edge.