In the dynamic world of manufacturing, the optimization of production methods is paramount to achieving efficiency and cost-effectiveness. One of the most innovative solutions that has gained traction in recent years is the utilization of press molds. As John Smith, a leading expert in the press mold industry, aptly stated, "The adoption of press molds revolutionizes the way products are manufactured, leading to enhanced precision and faster production times." This statement underscores the pivotal role press molds play in streamlining manufacturing processes.

Press molds not only enhance productivity but also significantly reduce waste, thereby contributing to a more sustainable manufacturing environment. By enabling manufacturers to create complex shapes and designs with minimal material loss, press molds provide a tangible solution to the challenges faced in traditional manufacturing methods. Furthermore, their ability to maintain consistency in mass production ensures that businesses can meet consumer demands without compromising on quality.

As we explore the top 10 benefits of utilizing press molds, it becomes clear that the integration of this technology is not just a trend, but a critical step towards modernizing manufacturing practices. From improved product durability to reduced cycle times, press molds are poised to transform the landscape of manufacturing solutions, paving the way for a more efficient future.

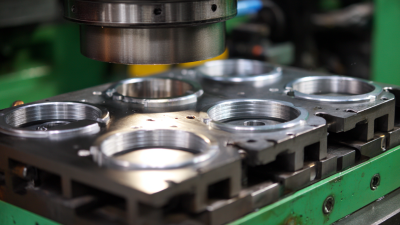

Enhanced precision in manufacturing through the use of press molds is redefining production capabilities across various sectors. Press molds provide a unique advantage in maintaining rigorous tolerances and consistency, which is crucial for high-quality outputs. Recent reports indicate that the injection molding market is projected to surpass $425 billion by 2032, driven by advancements in molding technologies and increasing demand for precision-engineered components. This surge emphasizes the significance of tools like press molds in meeting the growing expectations for accuracy in modern manufacturing.

Furthermore, innovations in thermoset insert molding showcase how precision can significantly enhance product strength and durability. By integrating cutting-edge molding techniques, companies are reducing waste while improving the structural integrity of their products. With environmental sustainability becoming increasingly important, manufacturers are now focusing on methods that combine precision with eco-friendly practices, thus contributing to a cleaner production process. As the industry continues to evolve, the ability to produce complex and customized designs with enhanced precision will be vital for staying competitive in a rapidly changing market.

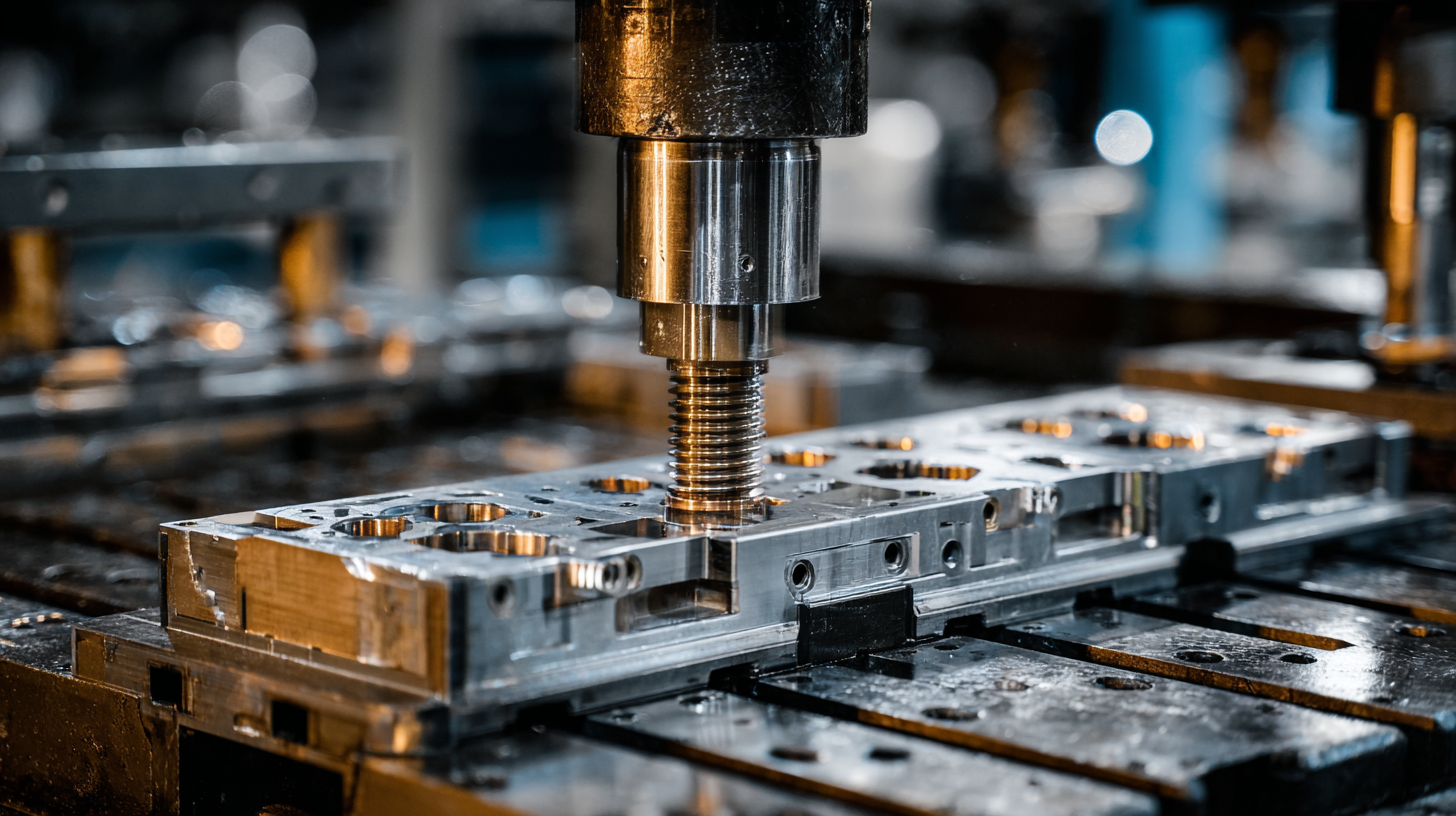

Press molds have emerged as a game-changer in the manufacturing industry, particularly when it comes to maximizing material utilization. By using press molds, manufacturers can significantly reduce waste during the production process. The precision and efficiency of these molds allow for optimal use of raw materials, which translates to lower costs and increased profitability. When every piece of material counts, adopting press molds becomes a strategic advantage for businesses aiming to streamline their manufacturing processes.

To make the most of press molds, consider these tips: First, always conduct thorough material tests to identify the best fit for your specific mold design. This ensures that you utilize materials that yield the best results, minimizing waste. Additionally, implementing regular maintenance of molds can enhance their lifespan and performance, leading to more efficient production runs. Finally, training your workforce on the importance of material conservation in conjunction with mold usage can foster a culture of efficiency that drives cost savings.

Incorporating press molds not only enhances production efficiency but also aligns with eco-friendly practices by reducing excess material. This commitment to sustainable manufacturing combined with cost-effectiveness positions businesses to thrive in a competitive landscape. As the industry continues to evolve, staying ahead with innovative solutions like press molds will be crucial for maintaining a strong market presence.

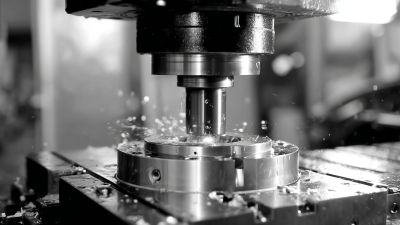

In the realm of manufacturing, streamlining production time is vital for maintaining competitiveness and meeting customer demand. Press molds have emerged as a pivotal solution in enhancing workflow efficiency. According to the "2021 Manufacturing Productivity Report" by the National Association of Manufacturers, companies utilizing advanced molding techniques, such as press molds, have reported a 25% reduction in production time. This significant improvement allows for quicker turnaround on projects and increased output without compromising quality.

Moreover, press molds facilitate consistent part production, minimizing defects and the need for rework. A study conducted by the Institute of Manufacturing Engineers revealed that businesses implementing press molding processes experienced a 30% decrease in defect rates. By ensuring each part meets stringent specifications, manufacturers can optimize their operations and focus resources on innovation and growth. With these efficiency gains, press molds not only accelerate production but also enhance overall product quality, creating a win-win scenario for manufacturers looking to thrive in a fast-paced industry.

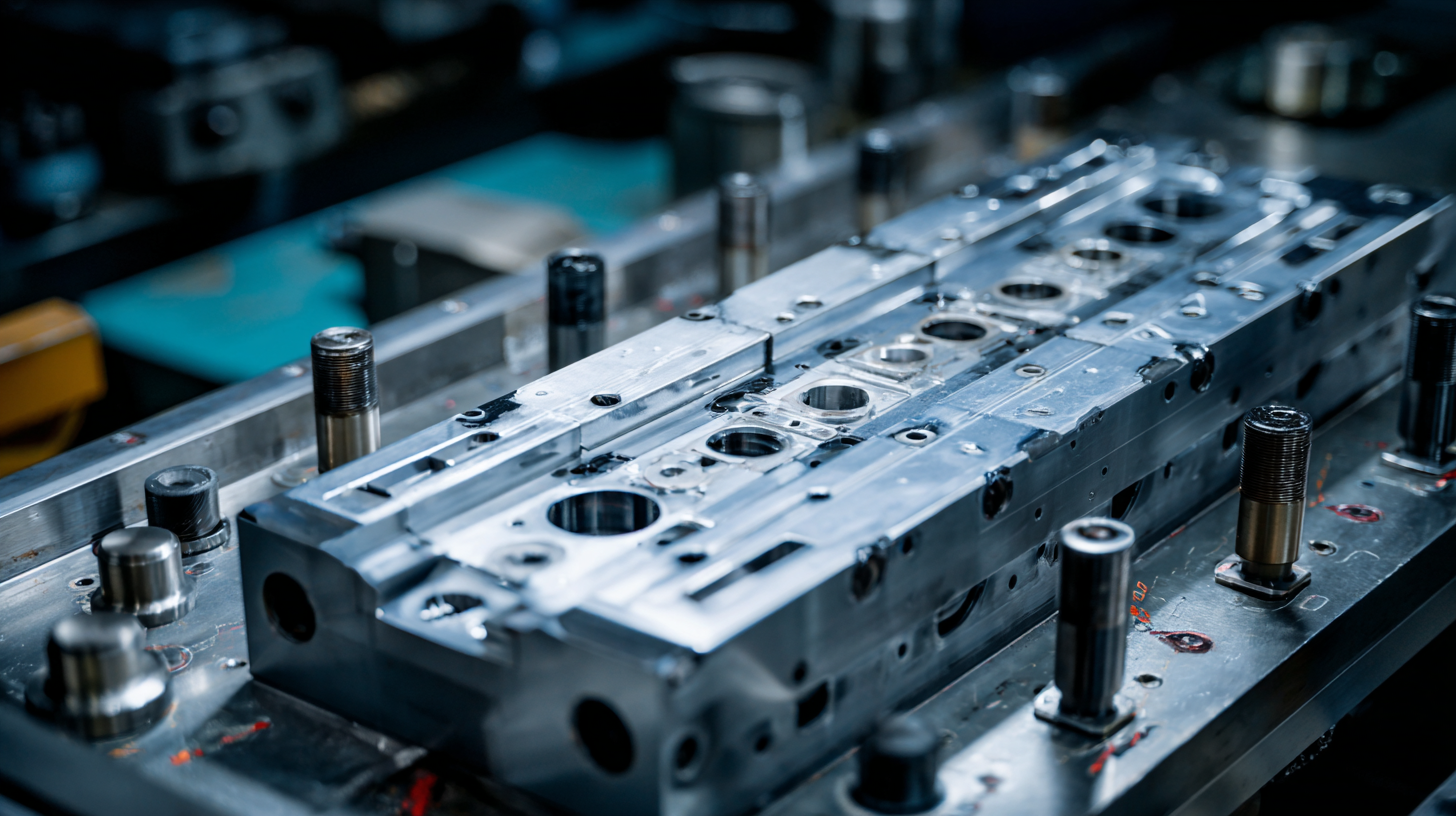

Press molds have gained significant traction in the manufacturing sector due to their remarkable versatility, accommodating a wide range of materials and production methods. According to the "Global Molds Market Report 2022," the demand for press molds is projected to escalate by 7.5% annually, driven by their ability to efficiently produce complex parts across various industries, from automotive to aerospace and consumer goods. This adaptability allows manufacturers to tailor press molds according to specific production needs, optimizing both design and functionality.

The flexibility of press molds not only enhances production capabilities but also significantly reduces lead times. A study from the Manufacturing Institute suggests that companies utilizing advanced molding techniques, including press molds, can cut production time by up to 30%. This is particularly beneficial in industries where rapid prototyping and quick market turnaround are crucial. Additionally, the ability to continuously innovate—such as incorporating new materials or modifying mold designs—ensures that press molds remain an essential solution in the ever-evolving manufacturing landscape.

| Benefit | Description | Applicability |

|---|---|---|

| Cost Effectiveness | Lower production costs due to reduced material waste and lower manufacturing times. | Ideal for high-volume production runs. |

| High Precision | Molds provide tight tolerances and uniformity in production. | Essential in industries such as aerospace and automotive. |

| Versatility | Molds can be customized for various shapes and sizes. | Applicable across different industries including electronics and consumer goods. |

| Improved Surface Finish | Produces smooth surfaces that often require less post-processing. | Beneficial in industries requiring aesthetic products. |

| Rapid Production | Faster cycle times lead to quicker product delivery. | Crucial for time-sensitive projects. |

| Material Flexibility | Compatible with various materials including metals, plastics, and composites. | Useful for diverse manufacturing needs. |

| Consistency | Ensures consistent quality across all produced items. | Important for brand reliability in consumer products. |

| Ease of Automation | Easily integrated into automated production lines. | Enhances productivity in large-scale manufacturing. |

| Reduced Labor Costs | Less manual handling needed due to streamlined processes. | Cost-effective for businesses focused on efficiency. |

| Environmental Impact | Potentially lower emissions and waste compared to traditional methods. | Increasingly important for socially responsible manufacturing. |

Automated press mold systems are revolutionizing manufacturing by significantly reducing labor costs while enhancing safety protocols. Traditional manufacturing methods often involve repetitive manual processes that not only demand a considerable workforce but also increase the risk of workplace accidents. By employing automated press molds, manufacturers can streamline operations, allowing machines to handle the bulk of the labor. This not only cuts down on the number of employees needed but also minimizes human error, resulting in a more efficient production line.

Moreover, the safety benefits of automated systems cannot be overstated. Automation mitigates the risk of injury associated with manual handling of materials and machinery. Operators can oversee multiple machines from a safe distance, reducing their exposure to potentially hazardous equipment. Furthermore, advanced technology integrated into press molds, such as sensors and emergency shutoffs, adds layers of safety that manual processes simply cannot match. By adopting automated press mold systems, manufacturers not only stay competitive but also foster a safer working environment for their employees.