In the rapidly evolving world of precision engineering, CNC machines play a vital role. These tools offer exceptional accuracy and efficiency. Industries like aerospace and automotive rely heavily on top-tier CNC technology. The right CNC machine can elevate production capabilities significantly.

Choosing the best CNC machine is not straightforward. Factors include size, speed, and precision. Some models excel in specific applications but might lack versatility. Others may be costly without delivering proportional benefits. It’s essential to weigh the options carefully.

Reflecting on the current market, advancements in CNC technology continue to emerge. Still, many users struggle to adapt. Training and understanding machine capabilities are crucial. Investing in the right CNC machine is a decision that can shape a company's future. Precision engineering depends on these choices. Your approach to selecting CNC machines matters greatly in the long run.

CNC machines have revolutionized precision engineering. They provide automated control over fabrication and manufacturing processes. This technology ensures high accuracy and efficiency in creating complex parts. Engineers can rely on CNC machines for intricate designs and seamless production.

Choosing the right CNC machine is crucial. Consider the type of materials you will work with. Some machines excel with metals, while others are better for plastics. Be mindful of the machine's specifications. Pay attention to its maximum spindle speed and travel limits. A machine that fits your needs can streamline your workflow.

Tip: Regular maintenance can enhance the machine's performance. Clean the tools and check for wear regularly. It helps prevent costly downtime.

There are inherent challenges in operating CNC machines. Even skilled operators face programming errors. Adjusting to new software can be frustrating. Don't overlook the importance of training. It is vital for optimizing machine usage. Proper training ensures your team can handle unexpected issues.

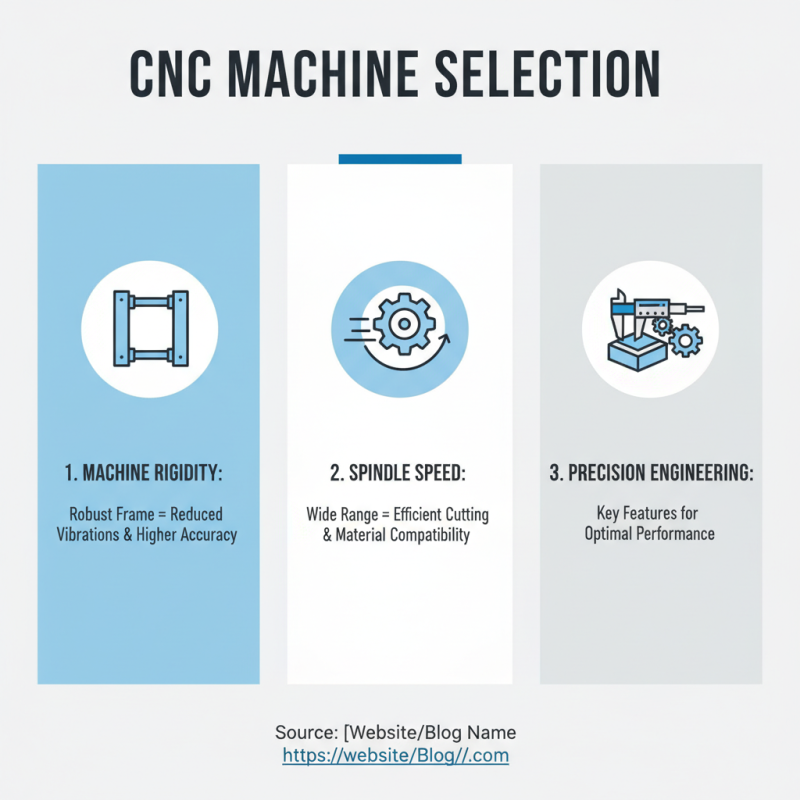

When choosing a CNC machine for precision engineering, several key features stand out. The rigidity of the machine is crucial for maintaining accuracy during operations. A robust frame helps reduce vibrations, leading to better precision. In addition, pay attention to the spindle speed range. Higher speeds can improve cutting efficiency and material compatibility.

Another important aspect is the software that controls the machine. User-friendly software can substantially reduce the learning curve. Look for machines that offer advanced features, like integrated simulation and real-time monitoring. These capabilities can enhance performance and reduce errors.

**Tip:** Consider your specific projects. What materials do you often use? Ensure the CNC machine can handle them effectively. Flexibility is vital in this evolving field.

Also, evaluate the machine's size and footprint. Match it with your workspace and production needs. Too large may restrict movement; too small may limit capability. In the end, knowing the intended use can guide your choice wisely.

In the fast-evolving world of precision engineering, selecting the right CNC machine is crucial. 2026 presents a variety of models that cater to diverse needs in this field. These machines offer outstanding performance but come with different sets of features and limitations. For instance, while some excel in speed, others shine in accuracy. The choice you make can shape your project's success.

When examining the top CNC machines, it's essential to consider factors like ease of use, adaptability, and support. Some models are versatile and can handle multiple materials, which is a significant advantage. However, others might require extensive training to operate effectively. Reflecting on how these aspects affect your workflow can lead to better decision-making. The right machine should not only meet current demands but also adapt as your projects evolve.

Precision in engineering demands rigorous standards. Various CNC machines can achieve remarkable results, but no model is perfect. Quality assurance is necessary, as slight defects can lead to significant issues. It's important to regularly review performance metrics and user feedback. This reflection can guide you toward making informed improvements in your manufacturing process.

| Model | Max Speed (RPM) | Precision (µm) | Table Size (mm) | Power (kW) |

|---|---|---|---|---|

| CNC Model A | 12000 | 5 | 800x400 | 7.5 |

| CNC Model B | 10000 | 6 | 1000x500 | 10 |

| CNC Model C | 8000 | 4 | 1200x600 | 8 |

| CNC Model D | 9000 | 3 | 600x300 | 5 |

In the realm of precision engineering, choosing the right CNC machine is crucial. A comparative analysis of various CNC machines reveals differences in performance that can impact production quality. Factors such as speed, accuracy, and versatility are often at play. High-speed machining can increase efficiency but may sacrifice detail. Seeking a balance is essential.

Tips: Always consider the type of material you'll be working with. Not all machines handle every material equally.

Another aspect to consider is user experience. Some CNC machines are more intuitive than others, but this can come at the cost of advanced features. Reflecting on ease of use versus capability can guide your decision.

Tips: Assess whether you need the latest features or if a robust classic machine suits your needs better.

It's important to test machines when possible. Real-world performance can differ from specifications. Different users have different needs, and a machine that suits one may not fit another. Be prepared for some trial and error in selecting the best fit for precision tasks.

The future of CNC technology in engineering is promising. As industries evolve, precision is crucial. Emerging trends focus on smart automation and AI integration. These technologies enhance efficiency and accuracy. CNC machines will become more user-friendly, with intuitive software interfaces. This shift opens opportunities for engineers of all skill levels.

Tips: Regularly update your skills. Understand how AI impacts your work. Adaptability is essential in this changing landscape.

Moreover, sustainability is gaining traction. CNC machines will likely use eco-friendly materials and processes. This shift is not just beneficial for the environment but also efficient. Engineers may need to rethink traditional methods. Waste reduction could enhance overall productivity.

Tips: Consider how sustainability affects supply chains. Engage with platforms discussing eco-technologies. Staying informed is key.

This chart illustrates the key features of the best CNC machines for precision engineering in 2026, rated from 1 to 10. Accuracy and speed are highlighted as the top attributes, while cost efficiency is a crucial consideration for many engineers.