In the fast-paced world of manufacturing, choosing the right CNC service is crucial. As we head toward 2026, industries are evolving rapidly. Many businesses struggle to find reliable service providers that meet their specific needs. Reliable CNC service can enhance efficiency and reduce costs. Yet, not all services deliver the quality or precision required.

Some manufacturers are still using outdated techniques. They may find it challenging to adapt to high-tech solutions. This may lead to inefficiencies and missed opportunities. Identifying the best CNC service means understanding your production requirements thoroughly. Organizations must assess their needs carefully before making a choice.

Investing in a quality CNC service can lead to significant improvements. However, companies must also consider their budget constraints. Balancing quality and cost is not always straightforward. Still, a well-chosen CNC service can transform manufacturing processes, driving success in a competitive market. Ultimately, businesses must reflect on their choices and adapt to stay ahead.

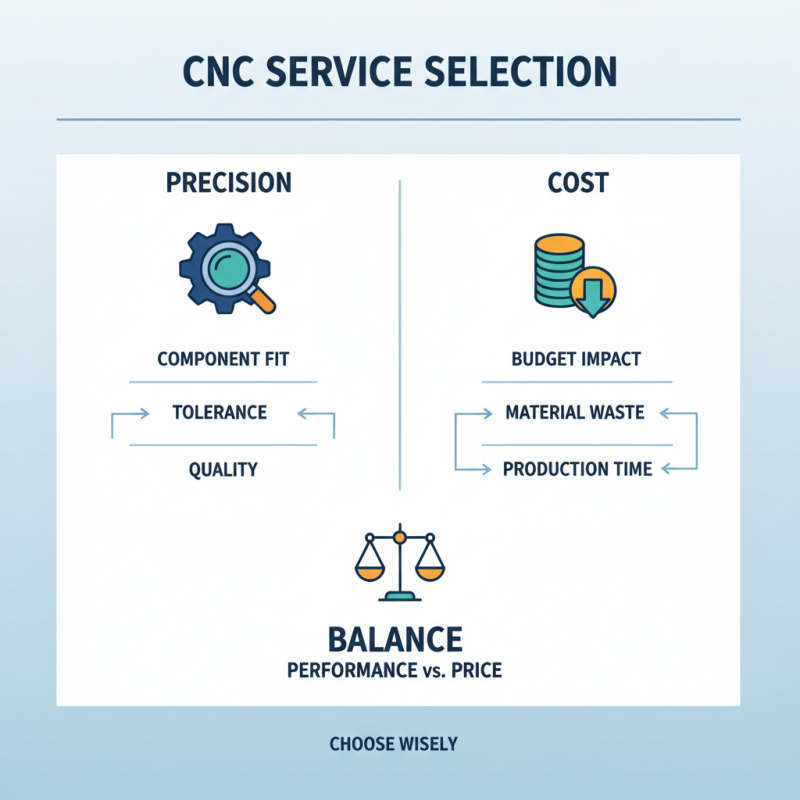

Choosing the best CNC service for manufacturing can be challenging. Factors like precision and cost play a vital role. Precision ensures your components fit perfectly, while cost affects your overall budget. It’s crucial to balance these two aspects.

Communication is another key factor. Clear dialogue with the service provider builds trust. It helps avoid misunderstandings about project requirements. Sometimes, you may need to refine your ideas. That’s okay; collaboration can lead to better results. Look for a service that encourages input and feedback.

Another aspect to consider is delivery time. Speed matters in manufacturing. A delayed project can disrupt your entire timeline. Some CNC services might promise quick turnarounds. However, rushing can lead to mistakes. Always assess their past performance and client reviews. Additionally, check their technology capabilities. Advanced machines often produce better outcomes. This can make a significant difference in quality. Be prepared to ask tough questions. It’s essential to find a service that fits your needs.

CNC services are vital for many industries. They provide precision and efficiency in manufacturing processes. Different sectors require various types of CNC services to meet their specific needs.

For instance, the automotive industry often uses CNC machining for producing complex engine components. These components demand high accuracy for better performance.

In the aerospace sector, CNC services help create lightweight parts from advanced materials. This industry prioritizes safety and durability. Therefore, manufacturers need reliable CNC techniques to maintain quality.

Custom fabrication is another critical type of CNC service. This is especially important in niche markets, where unique components are often necessary.

However, not all providers offer the same level of customization.

Some manufacturers may find that their expectations aren't fully met. They struggle with the balance between cost and quality. A CNC service that excels in one area might lack in another. Therefore, it's essential to assess multiple providers.

Find one that aligns with your specific goals.

Manufacturing is an evolving field, and CNC technology must adapt continually.

CNC machining services play a crucial role in manufacturing. Quality and precision are vital for efficient production. According to a recent industry report, 70% of manufacturers consider accuracy the most important factor. A small error in machining can lead to costly rework. This highlights the need for stringent quality control.

In evaluating CNC services, look for tools that provide detailed specifications. High-quality machines often have tolerances as tight as ±0.005 inches. However, not all providers achieve these standards. A survey indicated that 60% of manufacturers reported inconsistencies in their CNC service outputs. This inconsistency could stem from inadequate training or outdated technology.

Precision is not just about tools; it's also about people. Skilled operators can make a significant difference in output quality. Yet, 30% of service providers lack proper training programs. This gap can result in misalignment and defects. Investing in a CNC service that values both technology and talent is essential for achieving optimal results.

Cost is a crucial factor when choosing CNC services. According to a recent industry report, CNC machining costs can vary widely. Prices range from $15 to over $150 per hour. This variance often depends on material type, machine intricacy, and part dimensions.

For instance, aluminum components typically cost less to machine than intricate titanium parts. A study indicated that 60% of manufacturers prioritize cost when selecting a CNC service. However, focusing solely on price can lead to oversight. Quality sometimes comes at a premium. Selecting a cheaper option might result in lower precision or longer lead times.

It's essential to balance cost with quality. Investing in skilled CNC services ensures better end products. A well-made component can improve overall production efficiency. In the long run, quality work reduces errors. It also minimizes waste, saving money and time. CNC services should align with your specific manufacturing needs. A thoughtful approach is more beneficial than chasing the lowest price.

Emerging trends in CNC technology are reshaping the manufacturing landscape. Automation and AI integration are at the forefront. According to a 2023 report from the International Federation of Robotics, the number of industrial robots in CNC applications is expected to grow by 30% in the next five years. This surge will enhance precision and reduce production times significantly. Manufacturers must adapt swiftly to maintain competitiveness.

Moreover, sustainability is becoming pivotal. A recent study revealed that approximately 70% of firms are investing in eco-friendly CNC solutions. Energy-efficient machinery and waste reduction practices not only improve margins but also meet consumer demand for sustainability. However, companies often overlook the initial investment costs, making it challenging to transition. Striking the right balance between innovation and budget constraints remains a pressing issue.

Lastly, the trend towards customization through CNC technology raises questions. While tailored products can capture niche markets, they complicate supply chains. A 2022 survey indicated that 53% of manufacturers struggled with managing inventory for personalized offerings. As CNC capabilities expand, finding a solution to these challenges will be vital for future success in the manufacturing sector.