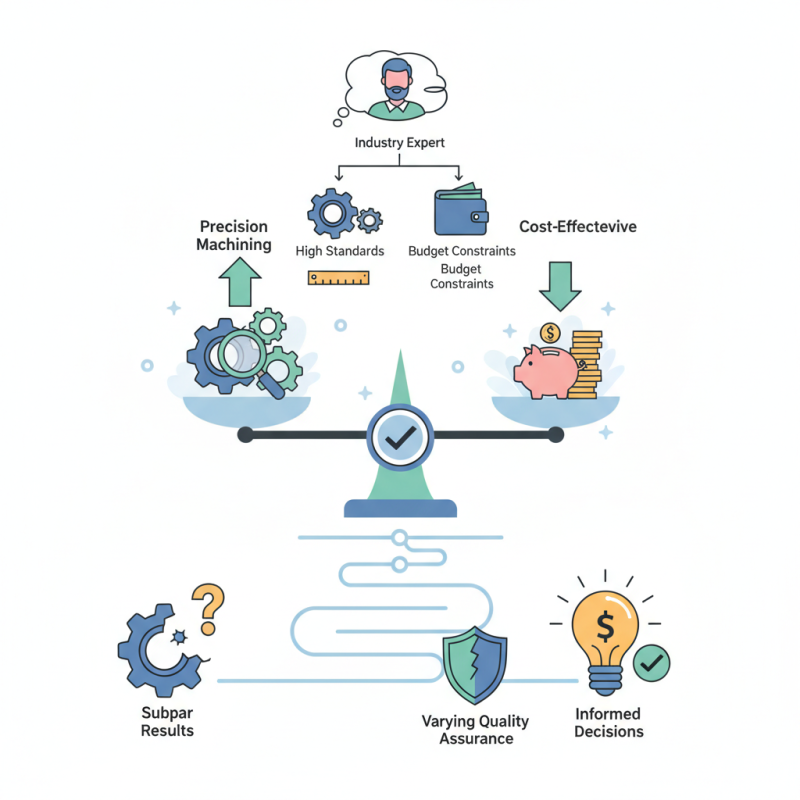

In the ever-evolving landscape of CNC service, finding a balance between quality and affordability is crucial. Industry expert, John Smith, once remarked, “Choosing the right CNC service can determine the success of your project.” His insight emphasizes the importance of selecting a provider that meets both budget constraints and high standards.

When considering CNC service options, businesses must evaluate their specific needs. Each project calls for unique specifications, and not all service providers offer the same level of expertise. Some may excel in precision machining, while others might focus on cost-effectiveness. These differences can impact the overall outcome and satisfaction.

However, navigating this industry isn't always straightforward. Cost-cutting measures can sometimes lead to subpar results. Quality assurance practices vary greatly among providers, leaving potential pitfalls for the unprepared. Reflecting on these challenges is essential for making informed decisions.

CNC services are evolving rapidly. In 2026, customers can expect improved precision and efficiency. The technology behind CNC machining continues to advance, allowing for faster production times. However, finding the right balance between quality and affordability remains a challenge.

Consider various factors when selecting CNC services. The expertise of machinists matters a lot. Skilled professionals can interpret complex designs and deliver better results. Yet, some companies may cut costs by hiring less experienced workers. This could lead to subpar outcomes and increased waste.

Communication is another crucial element. Clients need to articulate their needs clearly. Misunderstandings can result in errors and delays. Additionally, always question the processes used. Are they sustainable? Can they be improved? By reflecting on these aspects, you can ensure better service quality and value.

When selecting CNC services, quality and affordability are paramount. Start by understanding your project’s specific needs. This can save time and reduce costs. For example, consider the materials and complexity involved. These elements influence pricing. A simple part may be less costly, while intricate designs may require a premium.

Tips: Assess the manufacturer's experience. Longevity can indicate reliability. Also, look at their portfolio. This showcases past work and standards. Reach out for samples if possible. This is essential for ensuring quality.

Another factor is communication. It can make or break a project. If the CNC provider does not respond promptly, it may signal future issues. Clear dialogue is crucial for addressing concerns. Discuss timelines upfront. Delays can be costly if not managed.

Tips: Trust your instincts. If something feels off, explore other options. Quality often comes with a higher price tag. However, don’t compromise too much on budget. Understand what you truly need for your project. Evaluate various quotes carefully to find the best fit.

When selecting CNC service options, cost analysis is crucial. According to industry reports, approximately 30% of companies choose CNC machining based primarily on budget constraints. While affordability is key, sacrificing quality can be a costly error. Many manufacturers emphasize the importance of quality materials, which can double the initial investment cost but significantly reduce long-term expenses.

For optimal results, it's essential to weigh quality against price. Reports indicate that businesses spend on average 15% more for high-quality CNC services. However, these services often yield better precision and efficiency. Poor-quality machining can lead to rework costs, pushing the total expenses even higher. Thus, it’s often a false economy to select the cheapest options without assessing the potential for defects and delays.

In the quest for balance, consider not just immediate costs. Maintenance and operational efficiency play vital roles as well. A cheaper service might seem appealing at first glance, but over time, hidden costs can accumulate. Quality CNC services often come with better customer support and reliability, factors that can save companies from headaches later on.

When selecting a CNC service provider, it's essential to compare features and pricing effectively. Many services offer varying levels of quality, precision, and turnaround time. Some may promise quicker services but compromise on quality. It's crucial to weigh speed against durability.

Different providers might specialize in certain materials or techniques. For instance, one service might excel in machining metals, while another may focus on plastics. Each has its strengths and weaknesses. Checking past reviews can reveal a provider's reliability. Look for real-world examples of their work.

Pricing can also vary greatly. Some charge per hour, while others may have flat fees. A lower price does not always guarantee quality. Sometimes, the cheapest option leads to dissatisfaction. Investing a bit more might yield better results and save headaches later on. Always ensure that the pricing model aligns with your budget while not sacrificing quality.

As we look ahead to 2026, the CNC machining industry will likely experience significant shifts.

Automation and AI integration are expected to be more pronounced.

A recent report indicates that 55% of manufacturers plan to invest in automation technologies within the next few years.

This transition aims to enhance efficiency but raises concerns about job displacement.

Sustainability is another critical trend. Many companies are adopting green practices.

Research shows that 70% of consumers prefer products made with sustainable processes.

This demand will push CNC service providers to find eco-friendly materials and energy-efficient methods.

Yet, meeting these standards can complicate production processes.

Moreover, the skills gap remains a pressing issue.

The industry faces a shortage of qualified workers. A study found that 45% of CNC shops struggle to find skilled machinists.

This gap can hinder growth and innovation. Companies need to invest in training programs to ensure a capable workforce.

Balancing quality, affordability, and technological advancement will require thoughtful strategies in the coming years.