In the realm of precision manufacturing, the selection of die mold components is critical. These components shape the production process and determine product quality. According to a report by MarketsandMarkets, the global die casting market is projected to grow to $88.56 billion by 2025. This growth emphasizes the importance of high-performing die mold components in efficient manufacturing.

Expert David Johnson, a recognized authority in the die mold industry, stated, “The right components can drastically enhance production efficiency.” This insight highlights the pressure manufacturers face to choose components that deliver reliability and precision. Yet, not all manufacturers prioritize this aspect. Some still struggle with outdated technologies, impacting their output and quality.

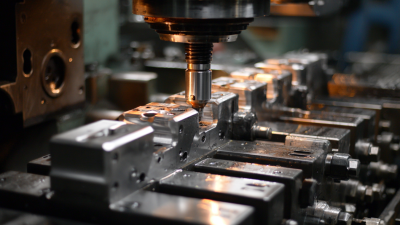

Moreover, the selection process for die mold components can be complex. Manufacturers must evaluate factors like material durability and design precision. A misstep here can lead to costly errors and production delays. Engaging with expert knowledge and industry standards can alleviate some of these challenges, steering companies towards optimal choices in die mold components.

Die mold components play a crucial role in precision manufacturing. They determine the quality, accuracy, and efficiency of the production process. Choosing the right components can greatly impact the outcome of manufacturing projects. Focus on materials, designs, and technologies that cater to specific needs.

Tips: Always evaluate the compatibility of materials. Not all materials suit every application. Consider the type of product being manufactured. A misstep here can lead to costly errors.

Optimizing die components requires a clear understanding of the manufacturing process. Keep in mind the environmental factors, such as temperature and pressure. These can significantly influence the molds' performance over time.

Tips: Regular maintenance is essential. Neglecting mold care can cause imperfections in the final product. Track wear and tear diligently to prevent unplanned downtimes. A proactive approach helps in maintaining precision and prolonging tool life.

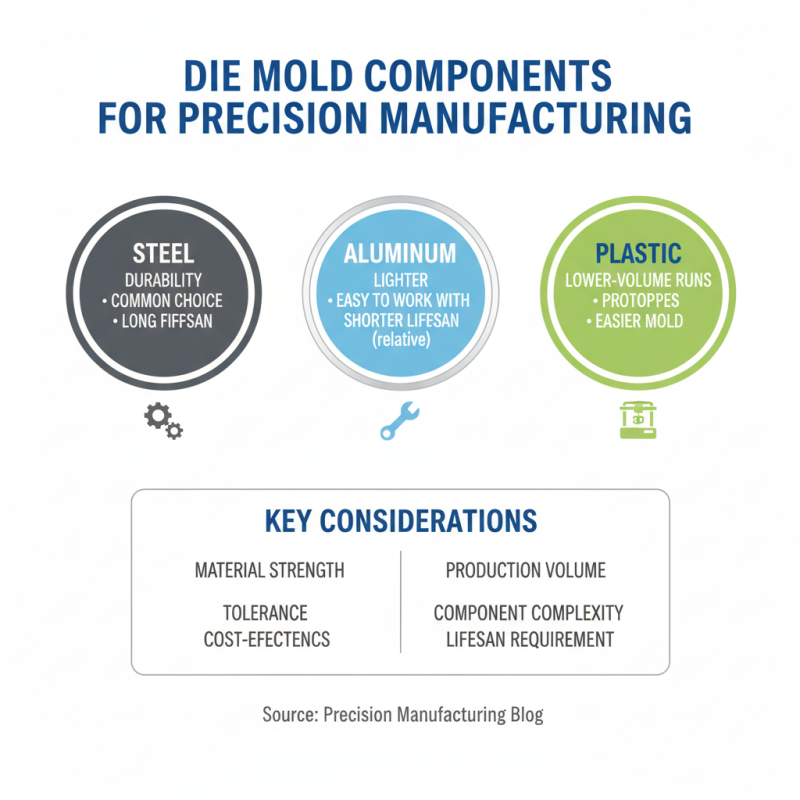

When it comes to precision manufacturing, understanding die mold components is crucial. These components come in various materials and types, each designed for specific applications. Steel is a common choice due to its durability. Aluminum is lighter and easier to work with but may not provide the same lifespan. Plastic materials are also available, ideal for lower-volume runs or prototypes.

Tips: Always assess your production volume before selecting materials. This helps in choosing the best option for your needs.

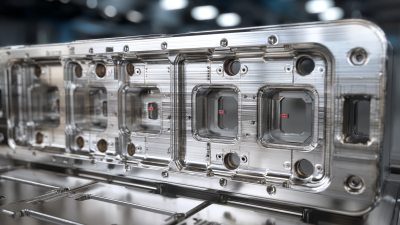

Different types of die mold components include cavities, cores, and inserts. Cavities form the external shape of parts. Cores create internal features. Inserts are used to facilitate complex geometries. Each element requires careful consideration for optimal results. It’s common to overlook the importance of fit between these components. Mismatches can lead to defects and longer production times.

Tips: Conduct regular maintenance checks on your molds. Small issues can escalate quickly, impacting precision and increasing costs.

Precision manufacturing relies heavily on the quality of die mold components. Selecting the right components is crucial for optimal performance and efficiency. Key metrics to consider include material properties, dimensional accuracy, and wear resistance. According to recent industry reports, molds made from high-grade steel show a 30% increase in lifespan compared to standard materials.

Dimensional accuracy impacts the final product's quality significantly. A report indicates that a tolerance level of ±0.01 mm can reduce scrap rates by nearly 25%. This precision ensures that parts fit together seamlessly, enhancing the overall production process. Furthermore, the right wear resistance can mitigate frequent replacements. A study highlights that upgrading to advanced coatings can double a mold's operational time.

Yet, there are challenges. Many manufacturers underestimate the importance of timely maintenance. Neglecting this can lead to workflow disruptions. Additionally, cost considerations can overshadow the need for quality. A cheaper mold may initially seem attractive but often results in higher long-term costs. The decision process requires careful evaluation of both short-term expenses and long-term performance.

Tolerance levels play a crucial role in die mold efficiency and product quality. A small shift in tolerance can lead to significant differences in the final product. Manufacturers often aim for tight tolerances to ensure precision, but achieving this can be challenging. It requires high-quality materials and advanced machining techniques.

However, it’s important to recognize that tighter tolerances do not always guarantee better results. In some cases, they can complicate the manufacturing process and increase costs. For instance, if parts are produced with extreme precision, any slight defect can render them unusable. So, balancing tolerance levels is key.

The impact of tolerance mismatches should not be underestimated. It can lead to workflow disruptions and waste materials. Evaluating tolerance levels often requires a thoughtful approach. Analyzing the specific requirements of each project can help in making better decisions. It's about finding that sweet spot where quality meets efficiency.

| Component | Material | Tolerance Level (mm) | Efficiency (%) | Product Quality Score (out of 10) |

|---|---|---|---|---|

| Core Inserts | Steel | 0.01 | 95 | 9 |

| Ejector Pins | Aluminum | 0.02 | 92 | 8 |

| Guide Bushings | Brass | 0.005 | 90 | 7 |

| Template Plates | Titanium | 0.03 | 94 | 9 |

| Cavities | P20 Steel | 0.015 | 93 | 8 |

The future of die mold component technologies is promising. Innovations are reshaping precision manufacturing. New materials and processes are emerging. These can enhance durability and reduce production times.

In recent years, additive manufacturing has gained traction. It allows for complex geometries that traditional methods cannot achieve. Companies are exploring lightweight materials that maintain strength. This shift can lead to better fuel efficiency in transportation. However, the integration of advanced technologies requires careful consideration. There are challenges in ensuring consistent quality and reliability.

Automation is another trend that cannot be overlooked. Robotic systems are being introduced to streamline operations. While these systems improve efficiency, they also bring risks. Over-reliance on automation may lead to skills gaps within the workforce. Regular training and human oversight remain crucial. Overall, while innovation drives progress, it also requires reflection on current practices.