In 2026, the demand for CNC milling services continues to rise. According to industry reports, the global CNC machining market is projected to reach $100 billion by 2025. This growth reflects an increasing reliance on precision manufacturing. Choosing the right CNC milling service can be overwhelming. Many providers boast advanced technologies and capabilities. However, not all services meet the specific needs of your project.

When selecting a CNC milling service, consider factors such as expertise and equipment availability. Quality assurance is crucial. A service that adheres to ISO standards can often ensure better results. However, not all providers can guarantee consistency. It’s essential to ask for case studies or customer testimonials. This information can help in assessing their reliability. Additionally, turnaround times vary widely. Some companies promise quick delivery, but this can compromise quality.

Ultimately, the choice of a CNC milling service should align with your project goals. Analyze your unique requirements and budget carefully. Understand that while many services offer competitive pricing, cheaper does not always mean better. Prioritizing quality can lead to longer-term gains. Remember, making the right choice now is an investment in your future success.

CNC milling is a crucial manufacturing process. It involves removing material from a workpiece using rotating tools. This technique offers precision and efficiency, making it popular across various industries. The automotive sector uses CNC milling for engine components. Aerospace companies rely on it for lightweight parts. According to a recent industry report, the CNC milling market is projected to grow by 5.2% annually.

Understanding CNC milling can help you leverage its benefits. Different materials, such as aluminum, steel, and plastics, can be milled. Each material requires specific milling strategies. Machine speed, feed rate, and tooling also play crucial roles. Many engineers suggest testing various settings to find optimal results.

Tip: Always communicate with service providers about your needs. This can prevent misalignments in expectations and final products. Define tolerances and finishes clearly.

Some small businesses may overlook CNC milling's intricacies. They may underestimate the importance of material selection or tool choice. This often leads to subpar finishes or costly mistakes. Take the time to research and understand the milling options available.

Tip: Regularly review your machining processes. Small adjustments can lead to better quality and efficiency. Keep track of what works and what doesn’t.

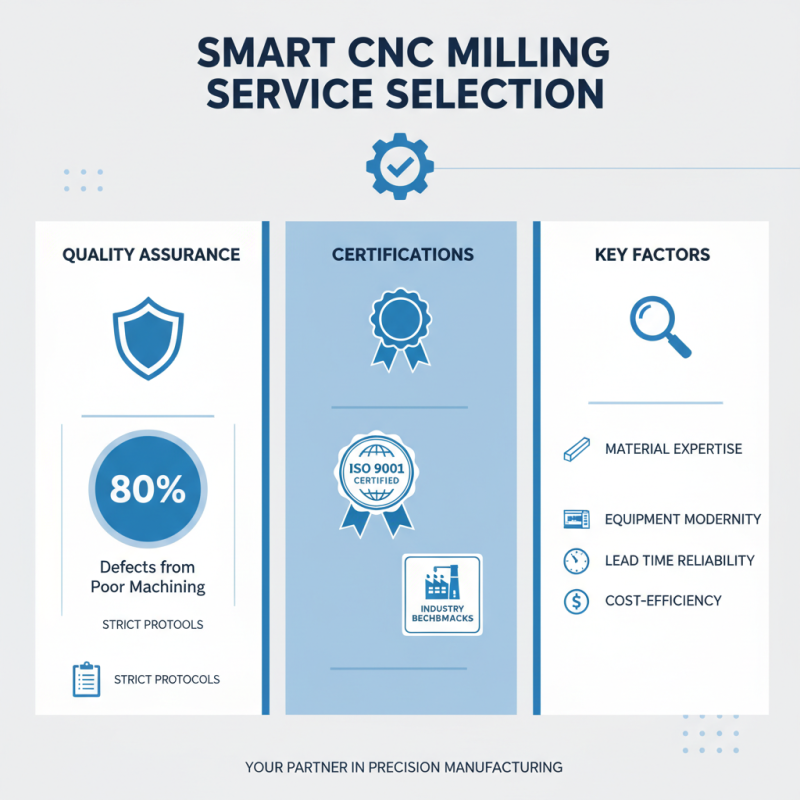

Selecting the right CNC milling service requires careful consideration of various factors. Quality assurance is paramount. Research shows that 80% of manufacturing defects arise from poor machining standards. Verify that the service provider follows strict quality protocols. Look for certifications demonstrating adherence to industry benchmarks, such as ISO 9001.

Technical capabilities are another critical aspect. Ensure the service can handle your specific materials and complexities. Some services specialize in metals, while others excel in plastics or composites. A provider with a wide array of capabilities can adapt to your changing needs. Check for advanced technology, like multi-axis milling. This can significantly enhance precision for intricate designs.

**Tip:** Always ask for samples of previous work. This allows you to assess their quality before committing.

Communication is crucial too. Gauge how responsive the service is during initial inquiries. A lack of communication may indicate future issues. Building a strong relationship can lead to a better understanding of your projects. Make sure they are willing to provide updates and feedback.

**Tip:** Be clear about your project's timeline and budget from the start. This sets the right expectations.

While price is essential, it shouldn't be the only consideration. Sometimes, cheaper options may lead to compromised quality. Balancing cost with quality can save money in the long run.

Choosing the right CNC milling service can be challenging. Evaluating the quality and capability of providers is essential. Start by examining their experience. A provider with years of operation likely has refined processes. Look for examples of previous work. A strong portfolio indicates their ability to meet complex requirements.

Tips: Ask for references. Speak with past clients about their experiences. Their feedback can reveal valuable insights.

Quality equipment is another key factor. Modern machines produce better precision. Check if the facility maintains its equipment regularly. Outdated technology can compromise product quality. Don’t hesitate to visit their workshop. Seeing the operation firsthand provides clarity.

Tips: Observe the cleanliness of the workspace. A well-organized shop often reflects professionalism. Trust your instincts about their capabilities.

It's also important to discuss the materials they work with. Some providers specialize in specific materials. If your project requires unique materials, ensure they can accommodate your needs. A lack of flexibility might limit your options.

Evaluating service responses is crucial. Quick replies often indicate a provider's commitment. However, consider the quality of their communication too. A provider should understand your vision, not just fulfill orders.

When selecting a CNC milling service, cost is a pivotal factor. Prices can vary significantly based on materials, complexity, and production volume. Consider the type of materials you need. Some materials are more expensive to machine than others. This discrepancy can drastically affect your overall budget.

It's essential to clearly outline your project requirements. Many services have different pricing models. Some charge by the hour, others charge per part. It's wise to request detailed quotes from multiple providers. This allows for better comparison and understanding of costs involved.

Don't overlook hidden costs. Shipping, finishing, and setup fees can all add to your expenses. Sometimes, a lower base price might lead to higher overall costs. Always read the fine print. Make sure to clarify all potential costs upfront. Also, take the time to evaluate the service quality against the cost. Sometimes, it’s worth paying a bit more for superior results. Balancing budget and quality can be tricky but crucial for success.

| CNC Service Factor | Description | Cost Estimate ($) |

|---|---|---|

| Setup Time | Time taken to configure the CNC machine for a job. | 200 - 500 |

| Material Type | Cost varies based on the raw material used (metal, plastic, etc.). | 50 - 2000 |

| Volume of Production | Number of units to be produced can affect pricing. | 100 - 5000 |

| Precision Level | Higher precision may increase costs due to technology and expertise. | 100 - 1000 |

| Surface Finish | Additional finishing processes can add to the overall cost. | 50 - 300 |

| Lead Time | Shorter lead times may incur expedited service fees. | 150 - 600 |

| Technology Used | Type of CNC technology (3-axis, 5-axis) influences cost. | 250 - 3000 |

Effective communication is essential when choosing a CNC milling service. Your project goals must be clearly articulated. Use simple language to express your needs. Share any technical requirements early on. This ensures everyone is on the same page. Avoid jargon that might confuse your CNC partner. Keep the dialogue open and transparent throughout the process.

Collaboration goes beyond just communication. Regular updates can help track progress. Schedule check-in meetings, even brief ones, to address any concerns. If issues arise, tackle them promptly. Reflect on feedback both ways. When mistakes happen, treat them as learning opportunities. This two-way street can lead to better outcomes and stronger partnerships. Engage with your partner; it fosters trust and can enhance the quality of the final product.