Choosing the right CNC service is crucial for your business. A suitable service can enhance production efficiency and product quality. It helps in meeting deadlines and customer expectations.

Many companies often overlook vital aspects when selecting a CNC service. They focus solely on cost while ignoring critical factors like material expertise and machine capabilities. Using the wrong CNC service can lead to production delays and increased costs.

Consider reviewing past projects and customer testimonials before making a decision. Communication with the CNC service provider is essential. Ask questions about their processes and capabilities. A perfect choice is rare; reflection on past mistakes can guide better decisions. Always strive for improvement and learn from experiences.

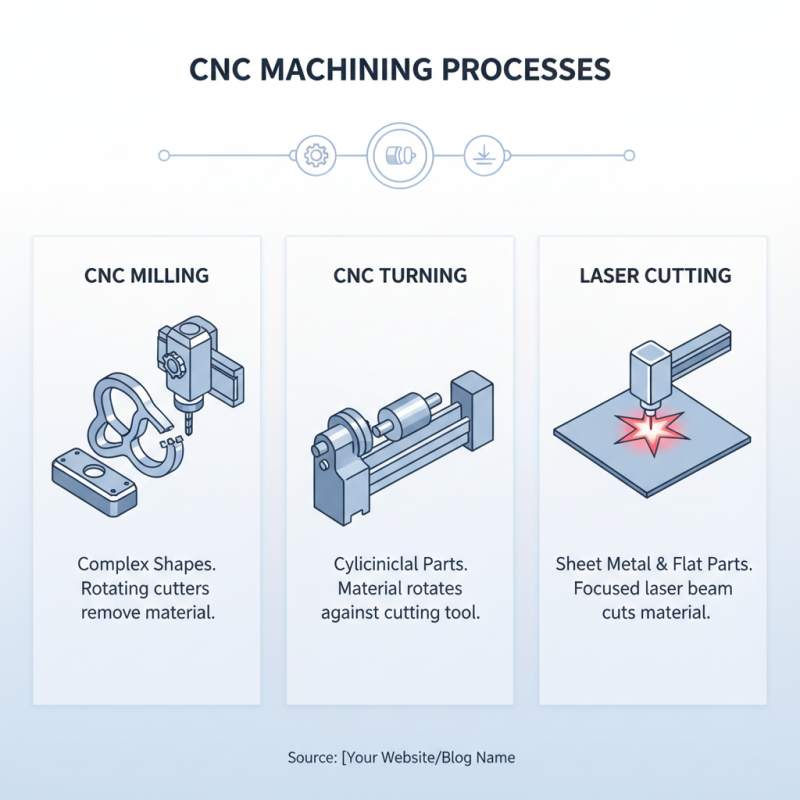

When selecting a CNC service, understanding the different types available is crucial. CNC machining encompasses several processes. These include milling, turning, and laser cutting. Each process has its strengths. For instance, milling is great for complex shapes. It uses rotating cutters to remove material with precision. Turning, on the other hand, is perfect for cylindrical parts. It shapes the material by rotating it against a cutting tool.

Laser cutting offers fast and accurate cuts. This method is ideal for thinner materials. However, it may not be suitable for thicker pieces. Choosing the correct service depends on your specific needs. Consider the material types and sizes you often work with. Also, think about lead times and production runs. Some services fit high-volume projects, while others excel in prototypes.

Many businesses find it challenging to pinpoint the right service. It can be overwhelming to navigate the options. Some may overestimate their needs. Others might select a service based on price alone. This can lead to quality issues down the line. Reflecting on your requirements will help narrow down your choices.

When selecting a CNC service provider, evaluating technical expertise is crucial. A recent industry report shows that nearly 75% of manufacturing companies attribute their productivity to effective CNC machining. This underlines the importance of choosing a provider with the right skill set. You should assess their qualifications, certifications, and industry experience. A well-rounded service provider often boasts a team that possesses advanced technical training.

It’s essential to ask about their technology and techniques. For instance, do they use the latest CAD/CAM software? Are they familiar with various materials? These details highlight their capacity to meet your specific needs. According to a survey, companies that utilize newer CNC technologies report a 30% increase in precision.

Don’t overlook customer reviews and case studies. They provide insights into the provider’s problem-solving abilities. A company that has navigated challenges successfully shows strength in its technical know-how. In some cases, providers may review projects lacking certain certifications. This can be a red flag. Assessing their past performance offers a glimpse into their operational integrity. These reflections can ultimately guide you to a more informed decision.

When selecting a CNC service, quality standards and certifications are critical factors. It is vital to assess the certifications held by potential CNC providers. ISO certifications, for example, indicate a commitment to quality and consistency. A service with such credentials likely adheres to industry best practices.

For effective evaluation, ask for documentation. Look for evidence of compliance with international standards. Don’t hesitate to request references from previous clients. They can provide valuable insight into the service's reliability.

Tips: Inquire about their quality control processes. Do they conduct regular inspections? Understanding their approach can reveal much about their operations. Always seek transparent communication. This simplifies the process and builds trust. Remember that a lack of clear information should raise red flags. If they are not forthcoming, it can lead to issues down the line. Your business deserves a service provider that prioritizes quality.

When selecting CNC services, price and quality often conflict. Research from industry reports shows that businesses typically prioritize cost savings. However, the phrase "you get what you pay for" rings true. Quality CNC work can enhance product durability and overall performance. A low-priced service might compromise on precision, leading to future costs in rework and material waste.

According to a survey by a leading manufacturing organization, nearly 70% of companies struggled with subpar CNC parts that did not fit specifications. These issues highlight the need for a balance between cost and quality. Some businesses opt for cheaper services, only to face delays and dissatisfied customers later. The cost of error can often eclipse the initial savings, proving that investing in quality is not always straightforward.

Consequently, businesses should assess the long-term impact of their CNC choices. Quality inspections and certifications may add upfront costs, but they can prevent significant losses associated with faulty parts. A meticulous approach ensures not only customer satisfaction but also builds a stronger reputation. Evaluating these pricing models requires careful thought and a willingness to reflect on past experiences.

When selecting a CNC service, it’s crucial to examine customer feedback thoroughly. Many providers present impressive portfolios, but individual experiences tell a different story. According to a recent industry report, 70% of customers choose a CNC service based on peer reviews. This highlights the importance of understanding past client experiences. Reviewing these insights can reveal strengths and weaknesses of a potential service provider.

Case studies offer another valuable perspective. They show real-world applications of services. For instance, one study found that businesses experienced a 40% reduction in lead times when partnering with a top-rated CNC supplier. Conversely, many companies reported delays and quality issues. This highlights the inconsistency within the industry. It’s wise to ask for specific examples of past projects, including challenges faced and how they were resolved.

While customer feedback is vital, it’s not infallible. Sometimes, services may receive mixed reviews due to unrealistic expectations. A service could be excellent in specific applications but not ideal for all. Engaging directly with previous clients can provide clarity. This deeper dive is essential for making an informed decision. Ultimately, knowledge gained from customer insights and case studies can guide you toward the best CNC service for your business needs.