Choosing the right moulds for your projects is crucial. Each mould can shape the outcome of your work significantly. Renowned expert in mould making, Thomas Grayson, once said, "The right mould is the foundation of every successful project." His insight reflects the importance of selecting the appropriate moulds for achieving desired results.

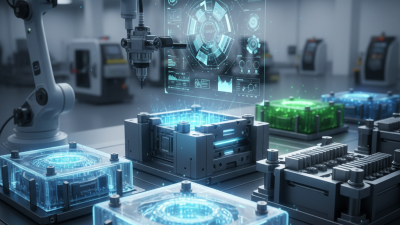

When diving into the world of moulds, one must consider various factors. The material type, durability, and design all play a vital role. For example, silicone moulds are flexible and provide a smooth finish. They can be ideal for intricate designs. Yet, they may not withstand high temperatures like metal moulds can.

It's not always a straightforward process. Mistakes can happen, such as choosing a mould that doesn't match your project's specifications. This may lead to disappointing results. Reflecting on past projects helps us learn, but we need to be more intentional in our choices moving forward. Selecting the right mould can transform an average project into something extraordinary.

Choosing the right moulds for your projects can greatly enhance outcomes. Different types of moulds serve varied purposes. From silicone to metal, understanding these types is crucial.

Silicone moulds are popular for their flexibility. They are ideal for intricate designs. Data shows that the market for silicone moulds has grown by 25% in the last three years. This reflects their increasing usage in crafts and food projects. However, they can wear out faster than expected. Users often overlook this aspect, leading to disappointing results.

On the other hand, metal moulds are known for durability. They can withstand high temperatures and are excellent for casting materials like concrete. A 2022 report showed that metal moulds account for 40% of the industry market. Nevertheless, they can be heavy and unwieldy. Many users struggle with handling them, indicating a need for better ergonomic designs. Understanding these nuances can save time and resources in your projects. Choose wisely, and always factor in the specific demands of your task.

Choosing the right moulds begins with understanding your project requirements. Assess the type of material you will be using. Common choices include silicone, metal, or plastic. Each material has unique properties affecting durability and flexibility. For instance, silicone moulds are ideal for detailed designs, but they may not withstand heavy use.

Evaluate your project’s scale. A small home craft might need a simple, reusable mould. In contrast, commercial production demands high-volume, durable moulds. The European Plastics Industry reported that 74% of manufacturers prefer custom moulds for efficiency. However, creating these can be cost-prohibitive for smaller projects, requiring careful budget assessment.

Consider the complexity of your design. Complex shapes often require more time and expertise. This can lead to unexpected costs and delays. A study from the American Society of Manufacturing Engineers shows that 55% of projects face time overruns due to mould complications. Reflecting on these factors helps you avoid pitfalls. Understanding your project's scale and complexity allows for informed decisions. This can lead to improved outcomes, saving time and resources in the long run.

| Project Type | Mould Material | Mould Size (mm) | Production Volume | Lead Time (weeks) |

|---|---|---|---|---|

| Consumer Goods | Plastic | 250x250 | 10,000 | 4 |

| Automotive Parts | Aluminum | 600x400 | 2,000 | 8 |

| Construction Components | Steel | 1200x800 | 500 | 12 |

| Medical Devices | Silicone | 300x300 | 5,000 | 6 |

| Electrical Enclosures | Polycarbonate | 450x300 | 8,000 | 5 |

Choosing the right mould material is essential. Plastic, silicone, and metal each have unique features. Plastic moulds are lightweight and inexpensive. They are great for beginners but may wear out quickly. If you plan to use them often, consider durability.

Silicone moulds are flexible and easy to clean. They can withstand high temperatures and are perfect for baking or crafting. However, they are often more expensive than plastic. If you enjoy intricate designs, silicone is a good choice. But keep in mind they might not hold up for heavy-duty uses.

Metal moulds offer strength and longevity. They provide even heating, making them ideal for precise results. Yet, they can be heavy and require more maintenance. Cleaning them can be a hassle. Reflect on your project needs and budget before deciding. Each material has its trade-offs.

This chart illustrates the cost per unit of different mould materials (Plastic, Silicone, and Metal), providing valuable insight for project cost assessments.

When choosing moulds for your projects, assessing their quality and durability is essential. The materials used in moulds can drastically influence their lifespan. Look for moulds made from high-quality plastics or silicone. These materials often resist wear and tear over time. However, not all moulds are created equal. Some may warp or degrade faster than expected.

It’s also crucial to consider how you will be using the moulds. For heavy-duty projects, sturdier options are necessary. If you're working with intricate designs, fragile moulds might not hold up effectively. Test a few options before committing to larger purchases. You may encounter issues like sticking or easy breakage, which are frustrating. Evaluating longevity is a balance of testing and intuition.

Additionally, think about how often you'll use each mould. A design that seems appealing may lose its charm after several projects. Moulds that are hard to clean or maintain can turn into a hassle. It’s essential to factor in your willingness to care for them over time. Sometimes, it’s worth investing more upfront in moulds that will endure numerous uses. Reflect on your experiences and the mold’s performance to make informed decisions.

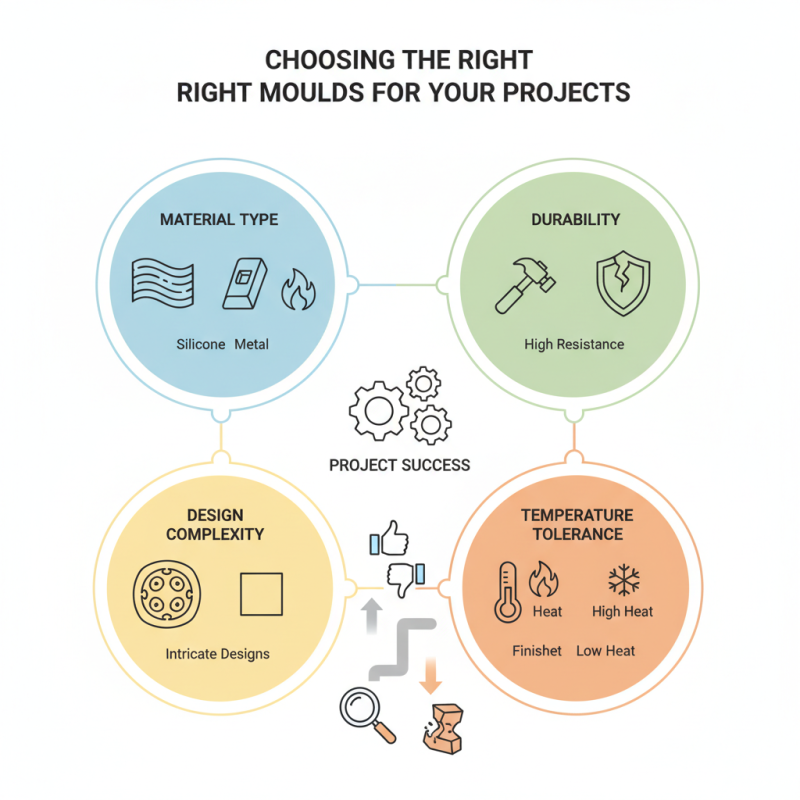

Choosing the right moulds can significantly impact the outcome of your projects. When budgeting for moulds, it’s essential to balance cost and quality. A recent industry report from the International Moulding Association indicates that over 40% of manufacturers prioritize cost over quality. This often leads to compromised end products.

Many cost-effective options exist without sacrificing quality. For example, using aluminium moulds can cost between $500 to $1500, depending on the complexity. In contrast, steel moulds range from $1500 to over $5000. The longer lifespan of steel moulds might justify the initial expense for larger projects.

However, finding the right balance is tricky. Some cheap moulds may lead to more defects, resulting in additional costs. A study shows that 30% of projects faced delays due to mould failures. Consider not just the initial investment, but long-term expenses. Investing in quality moulds can save money and time in the future.