As the world of manufacturing continues to evolve, CNC milling has emerged as a vital process for precision engineering and production. For beginners venturing into the realm of CNC milling, mastering the basics is essential to enhance their skills and capabilities. Renowned CNC milling expert, Dr. Emily Carter, once stated, "Understanding the nuances of CNC milling can transform a beginner into a skilled machinist, unlocking immense potential in production quality and efficiency."

This statement underscores the importance of not only learning the technical aspects of CNC milling but also developing an intuition for the process. The journey into CNC milling may appear daunting at first, but with the right tips and techniques, newcomers can quickly advance from novice to proficient operator. By focusing on foundational principles, understanding machine settings, and adopting best practices, aspiring machinists can significantly improve their craft.

In this guide, we will present the top ten CNC milling tips that can help beginners refine their skills and navigate the complexities of this sophisticated technology. Whether you're looking to enhance the quality of your work or just starting out, these insights will provide the edge you need to succeed in the exciting field of CNC milling.

Before embarking on any CNC milling project, it is crucial to establish a solid foundation of safety precautions to protect yourself and the workspace. According to the U.S. Bureau of Labor Statistics, more than 10,000 workplace injuries each year are attributable to machinery-related incidents. Hence, awareness and adherence to safety protocols can significantly reduce risks. Always wear appropriate personal protective equipment (PPE), such as safety goggles, hearing protection, and steel-toed shoes, to mitigate potential hazards.

Tip: Always ensure that your work area is clean and organized. Clearing away unnecessary tools and materials not only enhances productivity but also minimizes the risk of accidents caused by tripping or obstruction during operation.

Before starting your CNC milling, ensure that you thoroughly inspect the machine and its components. A study by the National Institute for Occupational Safety and Health (NIOSH) highlights that improper maintenance is a common factor in machinery accidents. Regular checks for wear and tear, calibration, and ensuring that all safety guards are in place are vital steps for ensuring a safe work environment.

Tip: Familiarize yourself with the machine's emergency stop features and the layout of your workspace. Knowing how to quickly shut down the machine can be pivotal in preventing accidents, especially in a busy workshop.

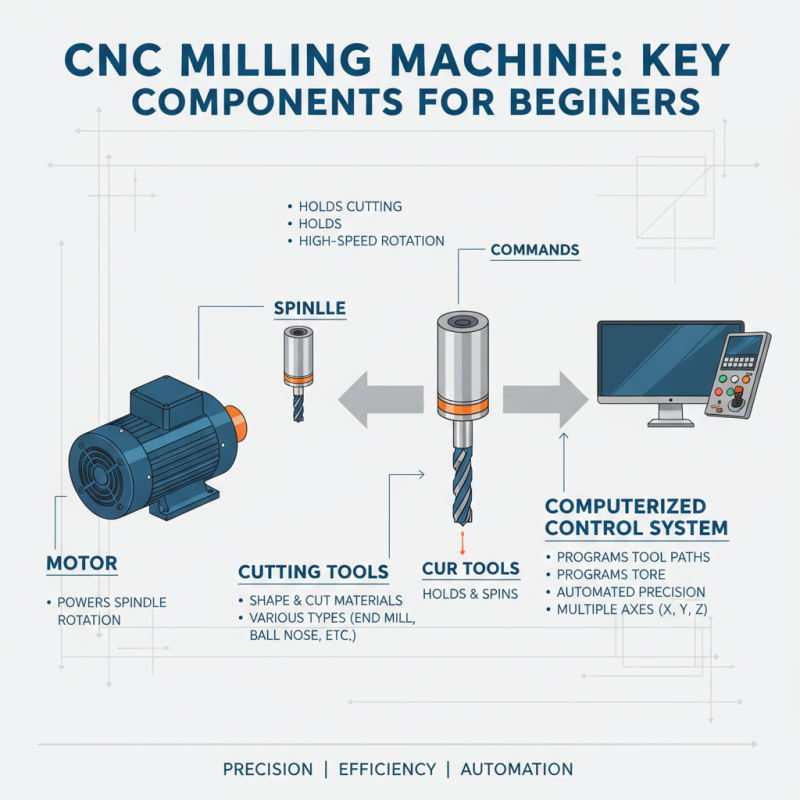

CNC milling machines are pivotal in modern manufacturing, offering precision and efficiency in creating complex shapes and designs. For beginners, understanding the main components of these machines is essential for mastering the milling process. A CNC milling machine generally consists of a motor, spindle, cutting tools, and a computerized control system. The motor powers the spindle, which holds the cutting tools and enables them to rotate while moving along multiple axes. Familiarizing yourself with how these components interact will significantly enhance your ability to operate and troubleshoot CNC mills effectively.

When starting your journey with CNC milling, keep in mind some valuable tips. First, always maintain your tools by regularly sharpening and cleaning them. Dull tools can ruin your workpiece and cause unexpected machine malfunctions. Secondly, it's important to set your workpiece securely in place to minimize movement during operation. A stable setup will not only improve the quality of your finished product but also ensure the safety of your work environment. Engaging with a supportive community of fellow beginners can also spur progress, as sharing experiences and challenges can lead to invaluable insights.

By focusing on the structure and function of CNC milling machines, as well as implementing practical tips, novice users can enhance their skills significantly. Understanding how each part works collaboratively will not only aid in effective operation but also pave the way for more advanced techniques in CNC milling.

Proper tool selection and setup are critical components in achieving precision and efficiency in CNC milling operations. For beginners, understanding the different types of tools available is vital. Each tool serves a specific purpose, from end mills and face mills to drills and reamers. Beginners should choose tools that align with the material they are working with; for example, harder materials require tools made from carbide rather than high-speed steel to ensure longevity and performance. Additionally, selecting the appropriate flute count can impact the cutting speed and finish quality; generally, more flutes enable smoother finishes but may reduce chip clearance.

Once the right tools are selected, setting them up correctly is equally important. This involves proper alignment and securing the tool in the spindle to minimize vibration during operation. It’s advisable to use tool holders that provide a stable grip and minimize runout, as any misalignment can lead to inaccuracies in the milled part. Moreover, adjusting cutting parameters such as speed, feed rate, and depth of cut according to the tool's specifications and the material being machined can significantly enhance the milling process. Ensuring that these elements are properly configured will not only improve the quality of the finished product but also extend the lifespan of the tools used.

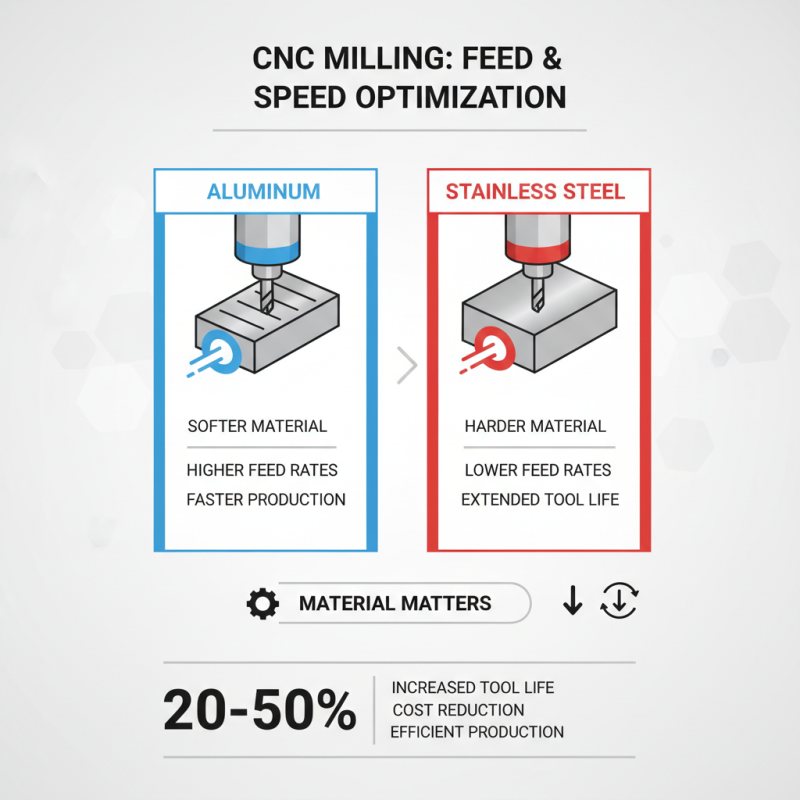

When optimizing feed rates and speeds in CNC milling processes, understanding the materials you are working with is crucial. Different materials require unique settings for optimal machining. For instance, aluminum typically allows for higher feed rates compared to harder materials like stainless steel due to its softer nature. According to industry reports, using the right feed rate can enhance tool life by 20% to 50%, allowing for more efficient production while reducing costs associated with tool wear.

Selecting the appropriate spindle speed is equally important. The spindle speed should match the characteristics of the tool and the workpiece material to achieve the best cutting conditions. A general rule of thumb is to use a higher spindle speed for smaller tools and softer materials and lower speeds for larger tools and harder materials. For example, a survey within the manufacturing sector showed that adjusting spindle speeds optimally can yield up to a 30% increase in production efficiency.

Tip: Always refer to the tooling manufacturer’s guidelines for recommended speeds and feeds. Additionally, implementing a feed rate calculator can help you achieve the best results, ensuring you are within the ideal range for your specific milling tasks.

When starting with CNC milling, beginners often fall into several common pitfalls that can hinder their progress. One significant mistake is neglecting the importance of proper machine setup. According to industry reports, approximately 30% of suboptimal milling results stem from improper calibration and alignment of the CNC machine. Ensuring that the machine is leveled, cutting tools are correctly installed, and the workpiece is securely clamped are essential steps that lay the foundation for quality milling work. Additionally, misjudging feed rates and spindle speeds can lead to tool wear and subpar finish quality, ultimately impacting project timelines and material usage.

Another frequent error is insufficient understanding of machining materials. A report by the Manufacturing Institute highlights that nearly 40% of new CNC operators overlook the specific properties of materials they are working with, leading to incorrect cutting parameters. Each material behaves differently under milling conditions, and lacking this knowledge can result in tool breakage or machining inaccuracies. Furthermore, failing to perform proper calculations for machining allowances can waste time and resources, as operators might find themselves backtracking to correct mistakes that could have been avoided with initial diligence.

By addressing these common mistakes, beginners can enhance their CNC milling skills and achieve more consistent, high-quality results.