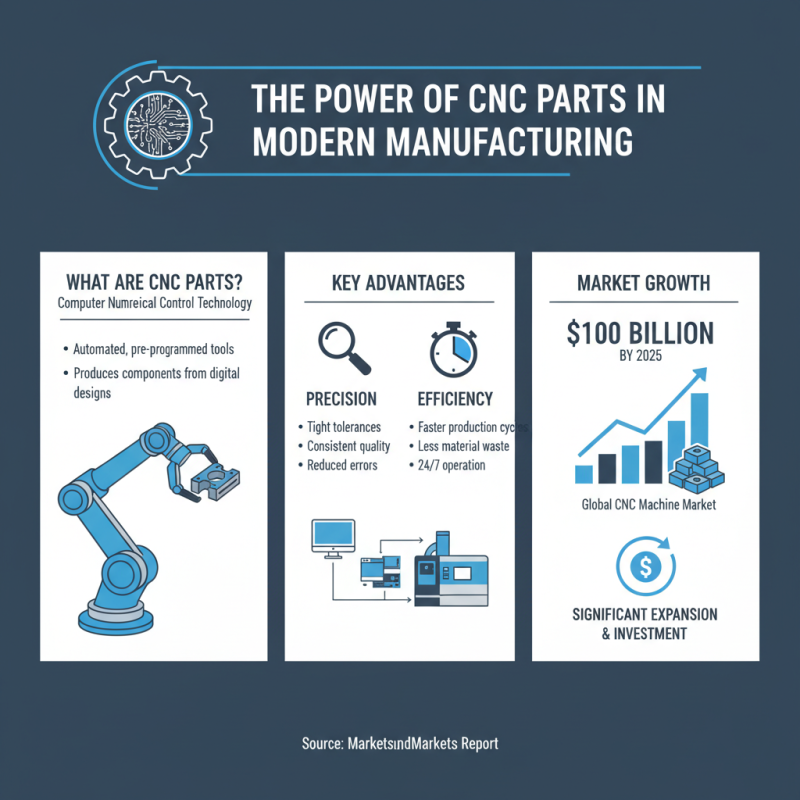

CNC (Computer Numerical Control) technology has revolutionized the manufacturing industry. By automating machine tools, it allows for precision and efficiency. The use of "parts for CNC" is crucial in various manufacturing processes, contributing to an increase in product quality and consistency. According to a report from MarketsandMarkets, the global CNC machine market is projected to reach $102 billion by 2025, showcasing its growing impact.

Experts in the field emphasize the importance of CNC parts. John Smith, a recognized authority in CNC technologies, stated, "Quality parts for CNC are vital for optimizing manufacturing efficiency." This highlights the critical role that properly machined components play in the overall CNC process.

However, challenges persist within the industry. Many manufacturers struggle to maintain the high standards required for these parts. As a result, some CNC machining operations face quality control issues that can adversely affect output. Continuous improvement in sourcing and producing parts for CNC remains essential.

CNC parts are essential components in modern manufacturing. CNC stands for Computer Numerical Control. This technology allows machines to operate with precision and automation. CNC parts are used in various industries, including aerospace, automotive, and electronics. According to recent industry reports, CNC machining can improve production efficiency by up to 30%.

These parts are typically made from materials like metal, plastic, and composites. The creation process often involves milling or turning operations. Each CNC part is designed for specific functions, such as gears, brackets, or housings. These components play critical roles in the assembly of larger systems. Accuracy is key. If a part is off by even a fraction, it can result in costly production errors.

Tip: Always ensure your design files are error-free. Double-check dimensions and tolerances before manufacturing. It's common to overlook small details, which can lead to big problems later. Another tip is to select the right material for your parts. Not every material suits every application. Testing prototypes can save time and resources during the production phase.

CNC machinery consists of several key components that work together to create precision parts. The heart of the system is the computer, which sends commands to the machine. This computer operates software that translates designs into machine language. The coding is essential. If there are errors in the code, the entire manufacturing process can falter.

Another critical component is the CNC controller. This directs the movements of the machine. It interprets the software commands, controlling speed, direction, and tools. Precision in these elements is vital. Even a slight miscalibration can lead to wasted materials and time. Tools are equally important. Various types such as drills, lathes, and mills are used in different applications. It’s crucial to select the right tool for the task.

Additionally, there are sensors involved that monitor the machine's performance. They ensure that everything is running smoothly. However, these sensors require regular maintenance. Neglecting this could result in mechanical failures. Regular checks might seem tedious but are essential for longevity and accuracy. Each of these components plays a significant role in creating finished products with high precision. Any weakness in one part can halt production completely.

CNC parts play a vital role in modern manufacturing. These components are fabricated using computer numerical control technology. This method improves precision and reduces human error. Operators can create complex shapes with minimal waste, which is essential for efficiency. CNC machines operate by following precise digital commands, transforming raw materials into finished products.

The fabrication of CNC parts begins with a detailed design. Engineers use CAD software to create a model. This model is then translated into machine language. CNC machines can cut, shape, and assemble materials like metal, plastic, and wood. The process is often quick but requires careful calibration. Inaccuracies can lead to poor outcomes, which can waste time and resources.

Tips: Always double-check your designs. Small mistakes can turn into big problems later. Keep your tools well-maintained for best results. Proper upkeep ensures accuracy and longevity of machinery. Understand that there may be a learning curve when using CNC technology. Embrace the challenges as part of the process.

| CNC Part Type | Material Used | Applications | Precision Level | Typical Tolerance |

|---|---|---|---|---|

| CNC Machined Parts | Aluminum | Aerospace Components | High Precision | ±0.01 mm |

| CNC Turned Parts | Stainless Steel | Automotive Parts | Moderate Precision | ±0.02 mm |

| CNC Sheet Metal Parts | Mild Steel | Enclosures | Standard Precision | ±0.05 mm |

| CNC Laser Cut Parts | Carbon Steel | Structural Components | High Precision | ±0.1 mm |

| CNC 3D Printed Parts | Plastic (PLA) | Prototyping | Low Precision | ±0.2 mm |

CNC parts play a crucial role in various manufacturing processes. These parts are machined components created using Computer Numerical Control technology. They offer precision and repeatability, essential for modern production. In industries like automotive, aviation, and medical devices, CNC parts are vital. Each of these sectors requires accuracy in its components.

Manufacturers use CNC parts for a range of applications. For example, in automotive production, CNC parts are used to create engine components and chassis parts. This ensures that each part fits perfectly, enhancing the vehicle's performance. In the medical field, CNC machined components are used to produce surgical tools and implants that need exact specifications to ensure patient safety.

However, it’s not always perfect. Some manufacturers struggle with the initial setup of CNC machines. Others find the learning curve steep. Ensuring quality control can also be challenging. Variations in material or machine calibration might affect the final product. Addressing these issues requires careful planning and attention to detail. In conclusion, while CNC parts are widely used, the process still needs improvement.

CNC parts play a crucial role in modern manufacturing processes. These components are produced using computer numerical control technology. This method enhances precision and efficiency in production. According to a report by MarketsandMarkets, the CNC machine market is projected to reach $100 billion by 2025. This shows significant growth and interest in CNC technology.

One clear advantage of using CNC parts is the reduction of human error. Traditional manufacturing often relies on manual labor, which can lead to inconsistencies. With CNC machinery, parts are manufactured to exact specifications every time. A study from Grand View Research highlights that CNC machines can improve productivity by up to 50%. This efficiency can lead to faster turnaround times and lower costs, especially in mass production.

However, reliance on CNC technology isn't without challenges. Initial setup costs can be high, making it difficult for small manufacturers. Additionally, there’s a learning curve for operators. Ensuring all staff are trained properly is essential. As industries continue to evolve, finding the right balance between automation and human skill remains a key consideration.