Choosing the right die mold components is crucial for the success of any project. Each component plays a significant role in the overall performance and quality of the final product. Mistakes in selection can lead to delays or increased costs, which can harm your project outcomes.

When evaluating die mold components, consider factors such as material durability and compatibility. It’s important to assess your specific needs. A component that works for one application may not be suitable for another. This requires thoughtful analysis and sometimes trial and error.

Additionally, you may face challenges in balancing cost with quality. High-quality components often come at a premium. However, investing in reliable die mold components can ultimately save money by reducing failure rates. Reflecting on past experiences, both good and bad, will help inform better decisions in the future.

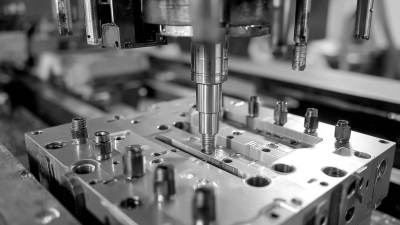

Understanding the different types of die mold components is crucial for any project. Each component serves a unique function. For example, the core and cavity are essential for shaping. The core creates the internal features, while the cavity forms the outer shape. Selecting the right materials for these components is vital. Steel and aluminum are common choices, but they have different properties.

Another critical component is the ejector system. This system helps remove the finished part from the mold. It can be complex, and mistakes can happen during design. Sometimes, the ejector pins may break or wear down too quickly, causing delays. Choosing the right configuration can prevent these issues.

Cooling channels are also important in die mold design. They help regulate temperature during the molding process. Inefficient cooling can lead to inconsistent product quality. However, designing the channels can be challenging. It requires careful planning and sometimes trial and error. These components work together, and understanding their roles is key to success in molding projects.

Selecting the right materials for die mold components is crucial for any project. According to a report by the Society of Plastics Engineers, up to 40% of manufacturing costs can be attributed to poor material choices. In die mold production, the materials must withstand high pressure and temperature. Steel, aluminum, and certain alloys are popular, but each has its unique properties. Steel offers durability, while aluminum is cost-effective and lightweight.

When considering material selection, it’s essential to balance cost and performance. Many engineers overlook the long-term implications of their choices. Certain materials may lead to faster production but can break down over time. Additionally, a study from the American Society of Mechanical Engineers highlights that choosing the wrong material can double maintenance costs. It’s a reminder that haste can lead to poor decision-making.

Environmental impact is also a vital consideration. As industries move towards sustainability, many manufacturers are exploring greener alternatives. However, the current options may not always match traditional materials in performance. This leaves a gap worth reflecting on. Selecting the right material is a complex decision, and sometimes experience may lead to biases. A fresh perspective can be beneficial in these scenarios.

When selecting die mold components, tolerance and precision are critical factors. Studies indicate that up to 70% of production errors arise from misaligned tolerances. A difference of just 0.01 mm can lead to defects in molded parts. This small variation often goes unnoticed until the final stages of production, resulting in costly delays.

Precision impacts not only the final product but also the efficiency of the manufacturing process. For instance, molds with higher precision levels tend to have longer lifespans. Reports suggest that these molds can last 30% longer than their less precise counterparts. However, achieving such precision requires careful planning and, surprisingly, often a higher initial investment. This trade-off between cost and quality must be carefully weighed.

In practice, many engineers overlook the importance of specifying tolerances correctly. They may assume standard values are sufficient, leading to unexpected issues. Regular calibration and checking of machinery also play a significant role in maintaining precision. A slight oversight can chase away potential reliability, jeopardizing the entire project. Fine-tuning these aspects is essential for optimal performance.

| Component Type | Tolerance Level (mm) | Precision Rating | Material Type | Application Area |

|---|---|---|---|---|

| Ejector Pin | 0.01 | High | Steel | Injection Molding |

| Core Block | 0.02 | Medium | Aluminum | Die Casting |

| Guide Pin | 0.005 | Very High | Hardened Steel | Stamping |

| Insert | 0.03 | Medium | Brass | Plastic Molding |

| Punch | 0.01 | High | Tool Steel | Sheet Metal |

When choosing die mold components, cost and quality are key factors to consider. A cheaper component might seem appealing at first. However, low-quality materials can lead to significant issues, including premature wear and production delays. You need to evaluate the long-term costs alongside initial expenses. A quality component might have a higher upfront cost but could save money in maintenance and replacement over time.

Here are some tips for obtaining the right components. Always assess the material used. Steel and aluminum have different lifespans and costs. For instance, aluminum molds are lightweight and less expensive but may not withstand heavy use. Think about your project's specific needs. Consider whether your project requires high precision or can tolerate minor variances.

Additionally, research the manufacturer's reputation. Good suppliers offer warranties. This can safeguard your investment. Remember, a well-made die mold contributes to higher production efficiency. Sometimes, taking the cheaper route leads to more expensive outcomes later on. Focus on finding a balance between cost and quality that aligns with your project's goals.

Selecting the right die mold components can be a daunting task. It’s essential to follow industry standards to ensure quality and efficiency. Start by understanding the specific requirements of your project. Each component plays a critical role in the overall performance. The wrong choice can lead to defects, delays, or increased costs. Pay attention to factors like material properties, dimensional tolerances, and surface finishes.

It’s also vital to consider the supplier's reputation. Not all suppliers adhere to the same quality standards. Verify their certifications and past client feedback. Communication is key here. If a supplier cannot clearly explain their processes, it raises red flags. Remember, quality assurance checks are not optional. Make them a priority in your selection process.

Another aspect to reflect on is whether the design is too complex. While intricate designs can offer benefits, they may also complicate the manufacturing process. Evaluate whether simplicity can achieve the same results. Regularly revisit your choices and be open to making adjustments. This adaptability can lead to improved outcomes in your die mold projects.