In the ever-evolving landscape of global manufacturing, the importance of selecting a reliable punching mould manufacture cannot be overstated. According to recent industry reports, the global demand for high-quality moulds is projected to grow significantly, with the market expected to reach $12 billion by 2025, reflecting a compound annual growth rate of 5.8%. As China's manufacturing capabilities continue to upgrade, the nation stands poised as a leader in providing innovative and efficient solutions for businesses worldwide. A focus on quality and precision in punching moulds not only enhances production efficiency but also ensures sustainability in manufacturing processes. Thus, understanding the criteria for choosing the right supplier is crucial for companies aiming to stay competitive in the bustling international marketplace.

When selecting a punching mould manufacturer, several key factors must be carefully evaluated to ensure the highest quality and reliability in your parts. First and foremost, consider the manufacturer’s experience and expertise in the industry. A well-established company with a proven track record is likely to have a deeper understanding of the complexities involved in the production process. Additionally, their knowledge of advanced technologies, such as hydraulic press technology, can significantly impact the quality of the aerospace and critical parts they produce.

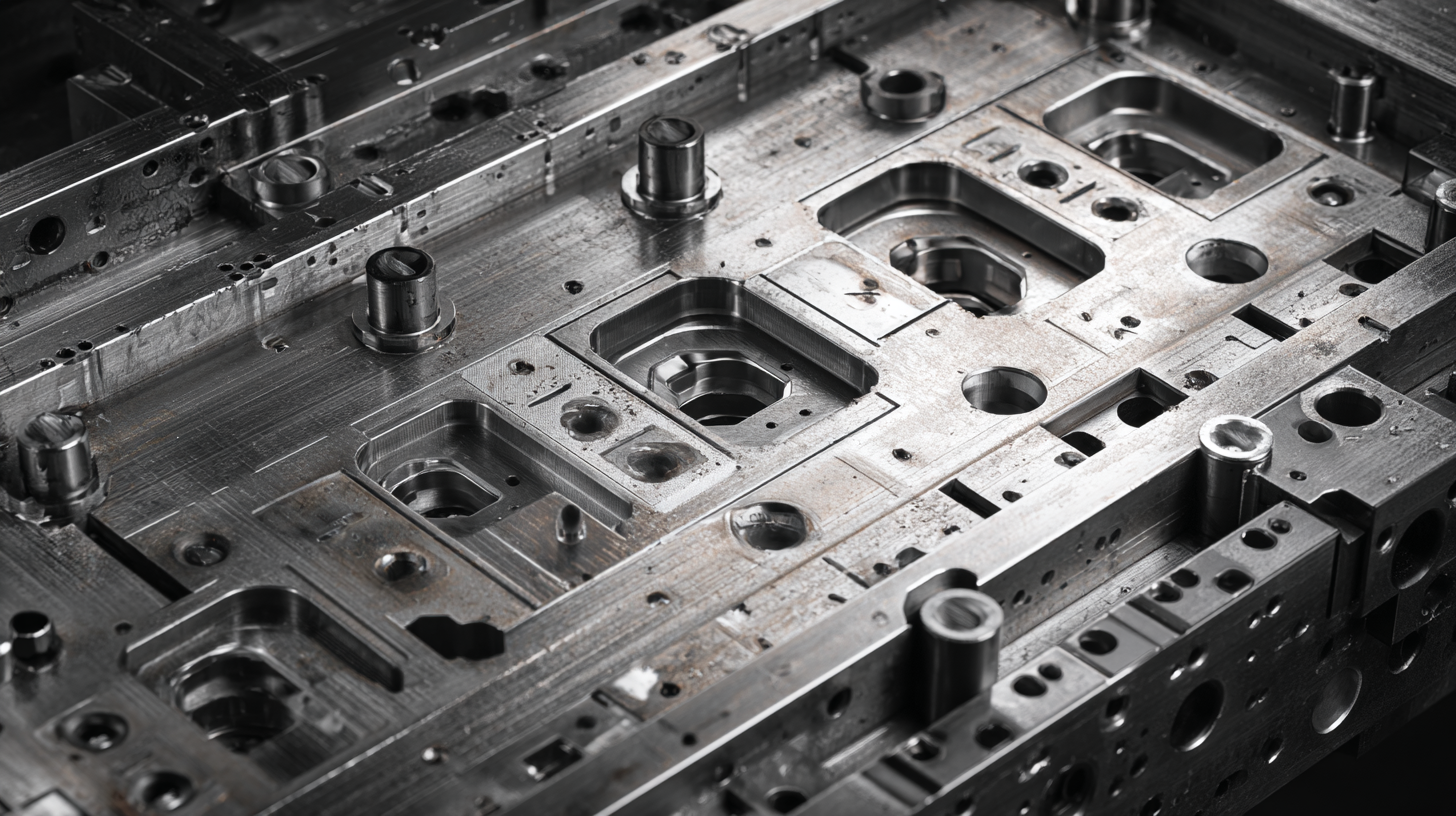

Another essential aspect to consider is the manufacturer's production capabilities and equipment. It’s vital to assess whether they utilize state-of-the-art machinery and techniques for mould manufacturing. A manufacturer that stays updated with the latest technology can provide precision and efficiency in their operations, leading to superior end products. Also, do not overlook their ability to offer customization options, as this flexibility can be crucial in meeting specific project requirements and ensuring the moulds are tailored to your needs.

When selecting a punching mould manufacturer, quality assurance is paramount. To ensure you find a supplier that meets your standards, it's essential to ask the right questions. Start by inquiring about their quality management system—specifically, whether they adhere to Total Quality Management (TQM) principles. A robust TQM approach can significantly enhance efficiency and customer satisfaction by promoting continuous improvement and staff engagement. Understanding their commitment to quality can provide insight into how they will manage your production needs.

Additionally, delve into their supplier sustainability practices. In 2025 and beyond, integrating sustainable practices is crucial not just for compliance but also for enhancing competitiveness in a global marketplace. Ask potential suppliers about their sustainability audit standards and how they measure their impact on environmental and social aspects. This will not only reflect their commitment to responsible sourcing but also ensure that your business aligns with sustainability goals, ultimately safeguarding it against global disruptions. Positively, this approach fosters a long-term partnership built on shared values.

When selecting a punching mould supplier, one of the critical considerations is whether to go local or international. According to a recent industry report by Grand View Research, the global mould manufacturing market was valued at $235 billion in 2021 and is projected to grow significantly, with Asian countries leading in production capability. Local suppliers may offer advantages such as reduced shipping costs and shorter lead times, enabling faster prototype development. These factors can be crucial for businesses requiring rapid turnarounds in a competitive landscape.

In contrast, international suppliers often benefit from larger economies of scale and advanced technological expertise. A survey conducted by Deloitte revealed that about 54% of manufacturers prefer sourcing components from international companies due to their ability to invest in high-quality machinery and skilled labor. However, companies must also consider potential communication barriers and logistical challenges when dealing with overseas partners. Balancing the pros and cons of local versus international suppliers is essential to ensure that the chosen punching mould manufacturer aligns with your specific operational needs and quality standards.

| Supplier Type | Supplier Location | Average Lead Time (Weeks) | Minimum Order Quantity | Quality Standards | Price Range (USD) |

|---|---|---|---|---|---|

| Local Supplier | USA | 4-6 | 50 | ISO 9001 | $200 - $500 |

| International Supplier | China | 8-12 | 100 | ISO 9001, CE | $150 - $400 |

| Local Supplier | Germany | 5-8 | 30 | ISO 9001, TS 16949 | $300 - $600 |

| International Supplier | India | 6-10 | 200 | ISO 9001 | $100 - $300 |

When selecting a punching mould manufacturer, evaluating supplier capabilities and track record is essential to ensure you partner with a reliable and competent supplier. A comprehensive assessment should start with the supplier's production capacity. According to a recent report by Grand View Research, the global mould manufacturing market is expected to reach USD 36.4 billion by 2027, underscoring the need for manufacturers to keep pace with growing demand. A capable supplier should demonstrate not only adequate production scale but also flexible manufacturing processes that can adapt to specific and evolving client needs.

Furthermore, examining a supplier's track record is crucial for assessing their reliability and quality assurance. A study from the American Society for Quality (ASQ) highlights that 63% of organizations reported improved performance metrics after implementing proper supplier evaluation processes. This involves reviewing customer testimonials, case studies, and any industry certifications that validate their quality. Additionally, consider their experience in the specific industry you operate in; suppliers well-versed in your niche often provide better insights into optimal designs and materials, significantly impacting the final product's quality and longevity. Understanding these capabilities can help ensure that your final moulds meet both performance and financial benchmarks.

When selecting a punching mould manufacturer, being aware of common red flags during the supplier selection process is critical. Recent guidance from the Bureau of Industry and Security (BIS) highlights new indicators of concern that can also apply to manufacturing contexts. For instance, a company facing unexpected supply chain disruptions or inconsistencies in quality may signal deeper issues such as vendor fraud or compliance violations. These concerns can be supported by the finding that over 50% of companies experience at least one vendor-related fraud incident, often rooted in inadequate due diligence.

Additionally, the digital landscape brings unique challenges. As highlighted in industry reports, swindlers increasingly operate through online channels, making it imperative for businesses to conduct thorough vetting. This includes assessing a supplier’s compliance with updated industry standards and verifying their reliability. A significant flag would also be a supplier’s unwillingness to share documentation regarding their supply chain practices. According to compliance experts, around 30% of organizations fail to implement effective forced-labour mitigation protocols, showcasing the importance of transparency in choosing a reliable manufacturer.