As the landscape of manufacturing continues to evolve, metal stamping stands at the forefront of innovation, driven by advancements in technology and design. According to a recent industry report by Grand View Research, the global metal stamping market is expected to reach USD 263.5 billion by 2025, with a CAGR of 4.3%. This substantial growth highlights the increasing demand for precise and cost-effective manufacturing solutions across various sectors, including automotive, aerospace, and electronics. In this context, exploring the future of metal stamping through the lens of emerging trends and innovations becomes crucial. The integration of automation, the rise of Industry 4.0, and advancements in materials technology are just a few elements that are reshaping the industry. This article will delve into these transformative forces, providing insights that manufacturers and stakeholders cannot afford to overlook.

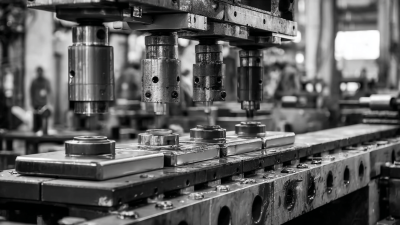

The integration of automation in metal stamping processes is revolutionizing the industry, significantly enhancing efficiency and product quality. According to a report by MarketsandMarkets, the global metal stamping market is projected to reach $210 billion by 2025, driven largely by advancements in automation technologies. Automated systems can streamline operations, reducing cycle times by up to 30%, which not only increases productivity but also lowers labor costs.

Moreover, automation aids in maintaining consistent quality in metal stamping. A study by the American Society for Metalworking and Technology indicates that automation can decrease defects by over 25% compared to manual processes. This is critical as industries demand tighter tolerances and higher-quality finishes. As manufacturers embrace smart technologies—such as robotics and advanced sensors—their ability to monitor and adjust processes in real time leads to superior output and reduced waste, positioning companies to better meet the demands of the market. The ongoing evolution of automation in metal stamping is an opportunity that cannot be overlooked by industry players aiming for sustainable growth.

The metal stamping industry is undergoing a significant transformation as it embraces sustainable practices aimed at reducing environmental impact. Innovations such as energy-efficient machinery and alternative materials are becoming focal points for manufacturers looking to minimize their carbon footprints. By incorporating advanced technologies like automation and IoT, companies can optimize production processes, thereby increasing efficiency and decreasing waste. This shift not only benefits the environment but also improves operational costs, making sustainability a key driver of competitiveness.

In addition to process optimization, the adoption of recycled materials in metal stamping is gaining traction. Manufacturers are exploring the use of scrap metal and eco-friendly coatings that reduce harmful emissions during production. These practices not only support the circular economy but also appeal to environmentally conscious consumers. As the industry evolves, collaborative efforts between manufacturers, suppliers, and regulatory bodies will be essential in fostering an ecosystem that prioritizes sustainability, paving the way for a greener and more responsible future in metal stamping.

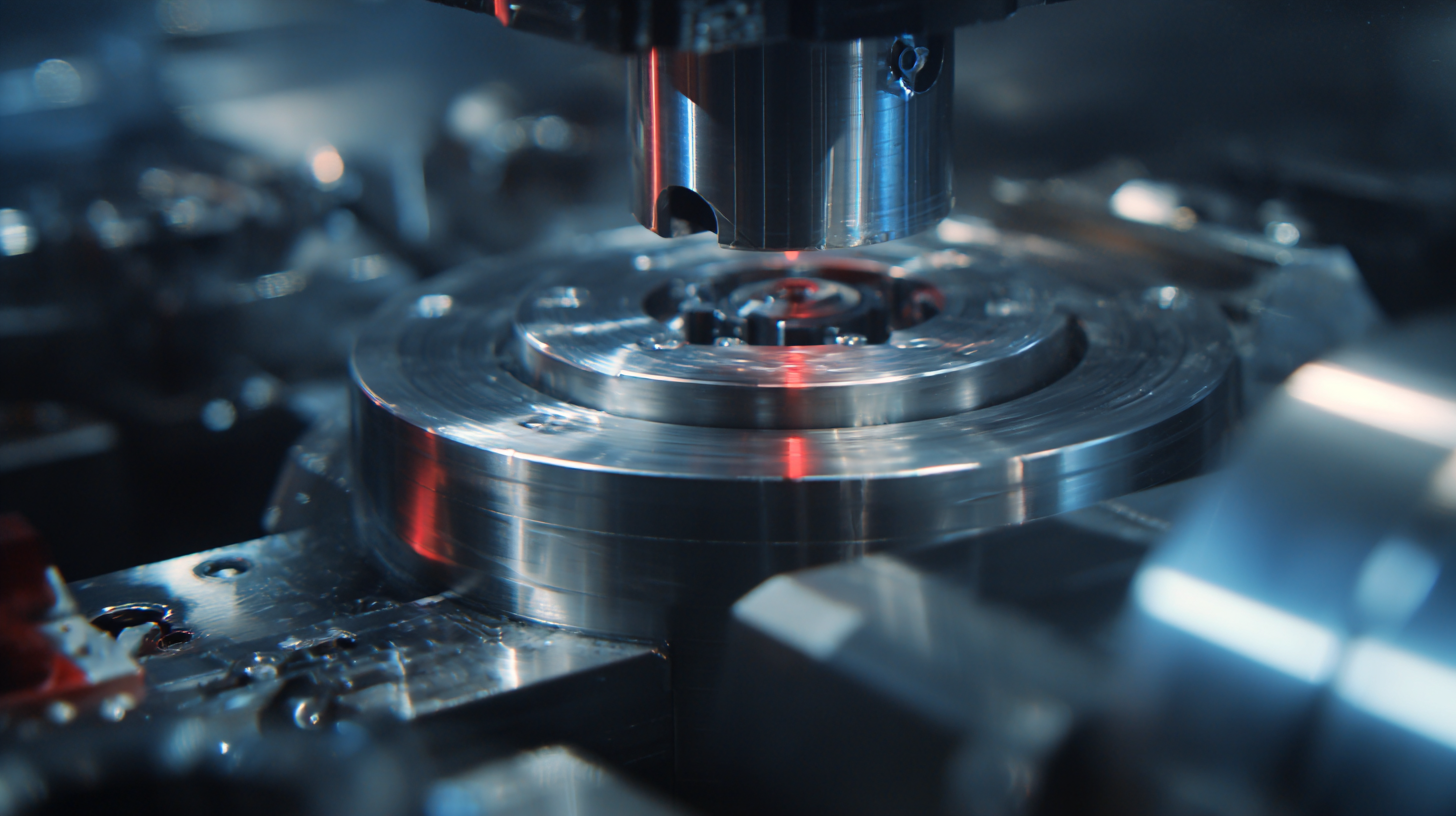

The metal stamping industry is witnessing a transformative shift with the incorporation of advanced materials, significantly enhancing performance and efficiency. As the global motor lamination market is expected to grow from USD 21.38 billion in 2025 to USD 30.89 billion by 2030, the demand for innovative materials within metal stamping processes is surging. This momentum is driven by the automotive sector's pursuit of lightweight solutions, where the lightweight cars market alone is projected to reach USD 130.30 billion by 2034. The use of advanced composite materials is becoming crucial in achieving these goals, allowing for better performance while reducing overall vehicle weight.

In the realm of composite materials, we see a rise in high-performance resins and adhesives, which offer superior bonding properties and durability. These materials are pivotal in metal stamping applications, contributing to improved production efficiency and product reliability. According to a report on the sheet metal market, a growing emphasis on advanced materials such as steel and aluminum will play a significant role in shaping industry trends through 2033. The integration of these materials paves the way for innovative manufacturing techniques and the robust performance of metal components in various applications, setting the stage for future advancements in the industry.

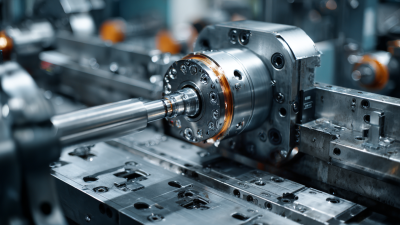

The metal stamping industry is undergoing a significant transformation driven by key technological trends that are reshaping its future. One of the most notable changes involves the adoption of digital manufacturing technologies, which enhance productivity across various sectors, including automotive and aerospace. Innovations in automation and artificial intelligence are streamlining processes, reducing waste, and increasing precision, which are crucial for meeting the demands of modern manufacturing.

Tips: When considering advancements in metal stamping, businesses should invest in training their workforce to effectively use new technologies. Continuous education in the latest tools and techniques will help maintain a competitive edge.

Additionally, the global automotive metal stamping market is projected to experience a healthy growth rate, with a CAGR of 5.1% expected in the coming years. With an increasing focus on lightweight materials, such as high-strength steel and aluminum, manufacturers are poised to enhance vehicle performance while adhering to sustainability goals. Adopting these materials not only improves energy efficiency but also aligns with the industry’s shift toward eco-friendly practices.

Tips: Companies should also explore partnerships with tech firms specializing in smart manufacturing solutions, as collaboration can lead to innovative methods and improved product outcomes.

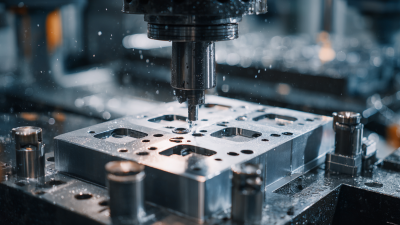

The integration of artificial intelligence (AI) in metal stamping processes is revolutionizing the industry by enhancing accuracy and efficiency. As manufacturers strive for precision, AI technologies are becoming indispensable tools. By combining deep learning algorithms with traditional stamping techniques, companies can optimize forming processes and significantly reduce errors. Recent studies highlight practical optimization strategies that leverage AI to improve the stamping formability of materials, such as AZ31 magnesium alloy. This not only streamlines production but also ensures high-quality outputs, thereby meeting the increasing demands of the market.

Moreover, the exploration of automated solutions in metal stamping is gaining traction. The implementation of intelligent robotics is enhancing the capabilities of CNC machines, enabling them to perform complex tasks with higher precision. Innovations like automatic strip layout design using genetic algorithms further illustrate the potential of AI in solving intricate design challenges in progressive die applications. As these technologies converge, manufacturers can expect a transformation in operational workflows, leading to a competitive edge in the evolving landscape of metal stamping.