The mold manufacturing industry is undergoing a transformative phase driven by innovative technologies and digital integration.

According to a report by MarketsandMarkets, the global mold market is projected to reach USD 21.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.9% from 2020.

This growth is significantly attributed to advancements such as additive manufacturing, which allows for more complex and efficient mold designs, and Industry 4.0 principles that enhance automation and data analytics in production processes.

Additionally, the increasing demand for lightweight materials in sectors like automotive and aerospace further propels the need for sophisticated mold solutions.

As we explore the future of mold manufacturing, it becomes essential to understand how these innovations not only improve efficiency and reduce costs but also address challenges in sustainability and customization.

Embracing these changes is crucial for industry players aiming to stay competitive in a rapidly evolving market landscape.

The future of mold manufacturing is being significantly shaped by innovative materials that enhance both production efficiency and final product quality. According to a report by the Global Mold Manufacturing Market Analysis, the use of advanced materials such as carbon fiber reinforced plastics (CFRP) and thermoplastic elastomers (TPEs) is projected to increase substantially, with the market for these materials expected to grow at a CAGR of 7.5% through 2027. These materials offer superior strength-to-weight ratios and increased durability, making them ideal for high-performance mold applications.

In addition to traditional materials, the adoption of additive manufacturing techniques is revolutionizing the mold making process. A study by the American Institute for Manufacturing Innovation reported that 3D printing technologies are leading to a 30% reduction in lead times and production costs. By allowing for more complex designs and the ability to create molds without the need for extensive tooling, these innovations not only streamline the manufacturing process but also enable the production of lightweight molds that contribute to sustainability goals within the industry. As these trends continue to evolve, it's clear that innovative materials will play a pivotal role in driving the efficiency and effectiveness of mold manufacturing in the years to come.

| Innovation Type | Description | Benefits | Key Trends |

|---|---|---|---|

| 3D Printing | Additive manufacturing techniques to produce complex mold designs. | Reduced lead times, lower production costs, and flexibility in design. | Rapid prototyping, customization. |

| Smart Molding | Integration of sensors and IoT to monitor the molding process. | Improved quality control and predictive maintenance. | Data analytics, Industry 4.0. |

| Eco-friendly Materials | Use of sustainable or recycled materials in mold production. | Reduced environmental impact and cost savings on material sourcing. | Sustainability initiatives, consumer demand for green products. |

| Simulation Software | Advanced software to model the flow and cooling of materials in molds. | Enhanced design accuracy and reduced trial-and-error time. | Virtual testing, optimization strategies. |

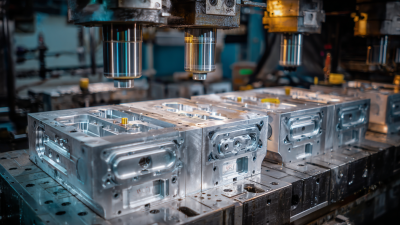

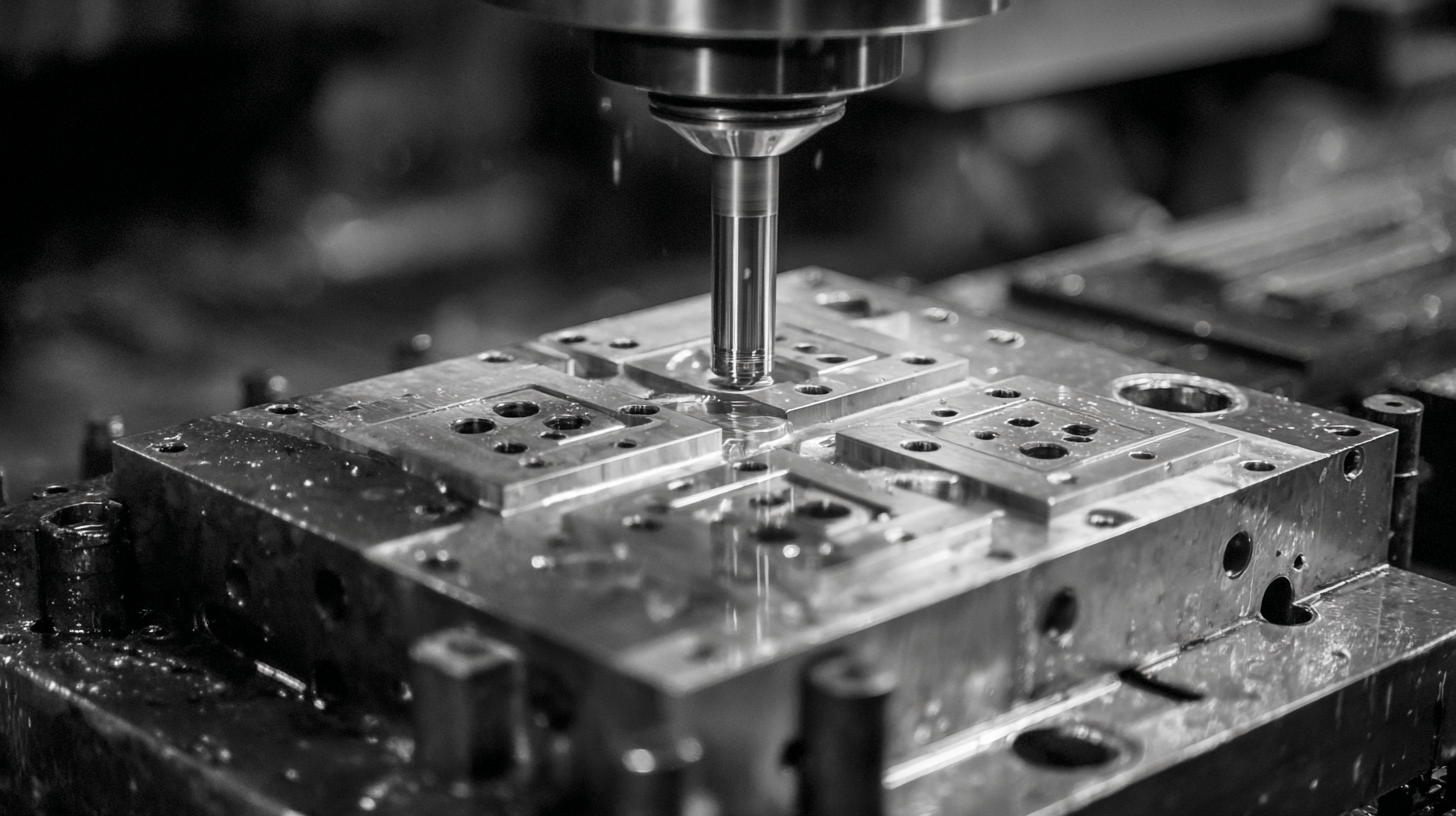

The landscape of mold manufacturing is undergoing significant transformation, largely driven by automation and robotics. According to a report by the International Federation of Robotics, the global market for industrial robots is expected to reach $70 billion by 2025, reflecting a compounding annual growth rate of 12%. This leap is largely due to advancements in robotics technology, which enable manufacturers to enhance accuracy, reduce operational costs, and significantly shorten production cycles.

Automation in mold production not only addresses the demand for faster outputs but also mitigates the risks associated with manual labor. With automated systems, the labor-intensive processes of mold making, such as machining and assembly, can now be performed with greater precision. A study by MarketsandMarkets indicates that the adoption of automation in manufacturing industries could lead to a productivity increase of up to 30% by 2025. By integrating advanced technologies such as AI and machine learning into their operations, companies can ensure consistent quality and minimize waste, propelling the industry forward into a more efficient future.

This chart showcases the impact of automation and robotics in modern mold production. The data illustrates the percentage growth in efficiency, quality, and cost reduction in the mold manufacturing industry from 2018 to 2023.

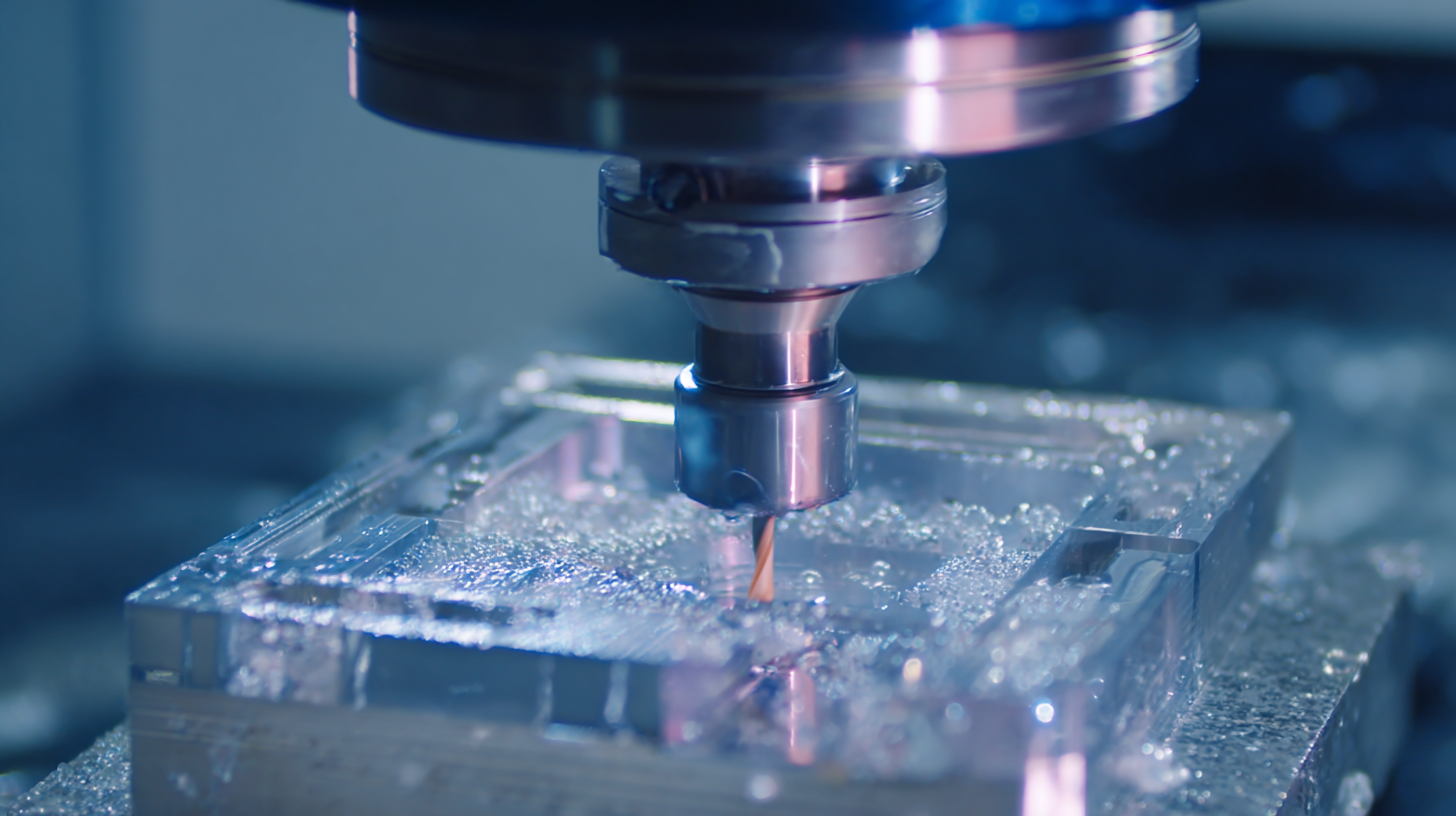

Recent advancements in 3D printing techniques are revolutionizing mold manufacturing, presenting new opportunities for efficiency and customization. Unlike traditional methods that often rely on subtractive processes, 3D printing enables the creation of complex geometries directly from digital models. This allows manufacturers to design molds that are not only lightweight but also optimized for thermal performance, reducing cycle times and energy consumption during production.

Additionally, the integration of advanced materials in 3D printing has further enhanced the mold-making process. Innovations such as metal 3D printing and high-performance polymers allow for molds that possess superior durability and precision. These materials can withstand extreme conditions, making them ideal for high-volume production runs. The shift towards additive manufacturing in mold making signifies a pivotal transformation in the industry, fostering creativity and enabling rapid prototyping, which ultimately leads to faster time-to-market for new products.

The mold manufacturing industry is witnessing a significant shift towards sustainability, driven by the urgent need for eco-friendly practices. As environmental concerns escalate, manufacturers are increasingly adopting greener approaches in their production processes. This includes the use of biodegradable materials and the implementation of energy-efficient technologies that reduce waste and minimize carbon footprints. Innovations such as additive manufacturing and 3D printing are also becoming more prevalent, allowing for precision molding with less material waste.

Moreover, companies are focusing on the lifecycle of molds, from production to disposal. Strategies such as recycling old molds and employing sustainable sourcing of raw materials contribute to a more circular economy within the industry. Businesses are not only meeting regulatory demands but are also responding to consumers' preferences for environmentally responsible products. This evolution signals a transformative period in mold manufacturing, where sustainability is not merely an option but a core principle guiding future innovations and practices.

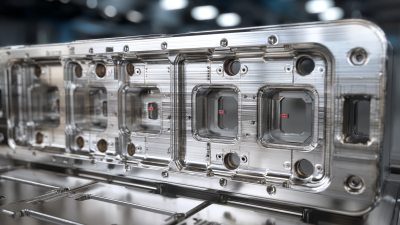

The integration of smart technologies into mold manufacturing is dramatically reshaping design and workflow processes. According to a recent industry report by MarketsandMarkets, the global smart manufacturing market is projected to reach $520 billion by 2025, underlining the growing trend towards automation and intelligent systems. One of the key innovations is the use of advanced software tools that enable real-time data analysis and simulation. This capability allows manufacturers to optimize designs before physical production begins, significantly reducing prototyping costs and time.

The integration of smart technologies into mold manufacturing is dramatically reshaping design and workflow processes. According to a recent industry report by MarketsandMarkets, the global smart manufacturing market is projected to reach $520 billion by 2025, underlining the growing trend towards automation and intelligent systems. One of the key innovations is the use of advanced software tools that enable real-time data analysis and simulation. This capability allows manufacturers to optimize designs before physical production begins, significantly reducing prototyping costs and time.

In addition, the deployment of IoT (Internet of Things) devices in mold manufacturing facilitates continuous monitoring of workflow efficiency. These devices collect data on machine performance, enabling predictive maintenance that can mitigate downtime. A study from Deloitte highlights that companies employing IoT solutions can reduce operational costs by up to 20%. By integrating smart technology, businesses in the mold manufacturing sector are not only enhancing their workflow but also aligning themselves with the Industry 4.0 paradigm, positioning them for sustained competitiveness in an evolving marketplace.