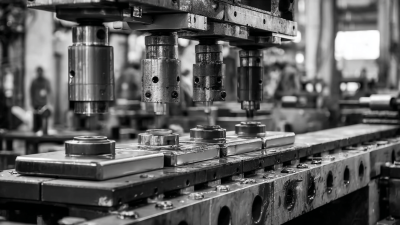

The manufacturing industry is on the brink of a significant transformation, driven by innovative technologies that are reshaping traditional processes. Among these advancements, the realm of stamping parts stands out, offering unprecedented efficiency, precision, and versatility.

As manufacturers begin to adopt digital solutions, such as automation, AI, and advanced materials, the potential for enhancing the production of stamping parts grows exponentially.

This exploration into the future of stamping parts reveals not only the critical role of technology in streamlining operations but also the emergence of new techniques that can reduce waste and improve sustainability.

In this context, understanding the innovations impacting stamping parts will equip industry leaders with the insights needed to remain competitive and responsive to the evolving market demands. Embracing these changes will be essential for companies aiming to excel in an increasingly complex manufacturing landscape.

The manufacturing industry is on the brink of a significant transformation, driven by innovative technologies that are reshaping traditional processes. Among these advancements, the realm of stamping parts stands out, offering unprecedented efficiency, precision, and versatility.

As manufacturers begin to adopt digital solutions, such as automation, AI, and advanced materials, the potential for enhancing the production of stamping parts grows exponentially.

This exploration into the future of stamping parts reveals not only the critical role of technology in streamlining operations but also the emergence of new techniques that can reduce waste and improve sustainability.

In this context, understanding the innovations impacting stamping parts will equip industry leaders with the insights needed to remain competitive and responsive to the evolving market demands. Embracing these changes will be essential for companies aiming to excel in an increasingly complex manufacturing landscape.

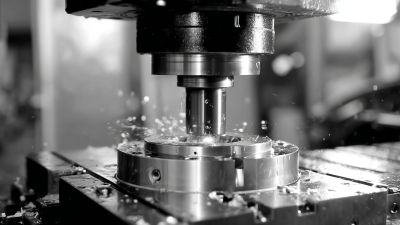

Recent advancements in stamping technology are playing a crucial role in the evolution of smart manufacturing environments. The integration of digital manufacturing technologies has notably enhanced productivity across various industries, allowing manufacturers to adapt quickly to changing market demands. These innovations facilitate more precise and efficient production processes, resulting in improved quality and reduced waste. As industries increasingly turn towards automation and smart solutions, the capabilities of stamping techniques are rapidly evolving to meet these new requirements.

In addition to technological advancements, the motor lamination market is experiencing significant growth, driven by the need for energy-efficient electric motors. The use of silicon steel in motor laminations is crucial for minimizing energy losses, emphasizing the importance of innovative materials in modern manufacturing. The metal stamping market, projected to see considerable expansion by 2032, is also adapting to emerging trends and demands, further showcasing the interconnectedness of these advancements. As manufacturers embrace digital tools and innovative practices, the future of stamping parts looks promising and pivotal for smart manufacturing.

The integration of AI and machine learning in stamping processes is revolutionizing the manufacturing industry. According to a report by MarketsandMarkets, the global AI in manufacturing market is projected to reach $16.7 billion by 2026, with a compound annual growth rate (CAGR) of 47.4% from 2021 to 2026. Utilizing advanced algorithms, manufacturers can optimize stamping operations by predicting machine failures, reducing downtime, and enhancing product quality. This proactive approach can lead to a significant reduction in operational costs, with some studies indicating savings of up to 20% in maintenance expenses.

Moreover, machine learning enables manufacturers to analyze vast amounts of data generated during the stamping process. By identifying patterns and anomalies, ML algorithms can fine-tune production parameters in real-time to improve precision and efficiency. According to a survey by Deloitte, 73% of manufacturers that deploy AI solutions experience improved production efficiencies. This integration not only enhances productivity but also supports the development of smart factories, where interconnected devices and systems seamlessly communicate to streamline operations, ensuring that the future of stamping parts is not only innovative but also highly efficient.

| Innovation | Description | Impact on Stamping Processes | Estimated Adoption Year |

|---|---|---|---|

| Predictive Maintenance | Utilizing AI to analyze machine data to predict failures before they occur. | Reduces downtime and maintenance costs, enhances productivity. | 2024 |

| Quality Inspection | AI-driven visual inspection systems that ensure product quality. | Minimizes defects, increases production speed, and lowers costs. | 2023 |

| Smart Robotics | Integration of AI with robotic arms for flexible automation. | Enhances efficiency in manufacturing processes with adaptive capabilities. | 2025 |

| Data Analytics | Analyzing production data to gain insights and optimize processes. | Increases efficiency and reduces waste in production lines. | 2023 |

| 3D Stamping Technology | Leveraging 3D printing techniques within stamping processes. | Allows for complex designs and reduces lead time for prototyping. | 2026 |

With the automotive metal market projected to reach USD 174.2 billion by 2033, growing at a CAGR of 4.50%, the focus on sustainable practices in stamping parts is more crucial than ever. Innovations in manufacturing processes that prioritize eco-friendly materials and production techniques are redefining industry standards. For instance, companies are beginning to adopt advanced technologies and materials that significantly reduce waste and energy consumption, aligning with global sustainability goals.

Recent initiatives showcase a commitment to the circular economy, with businesses exploring ways to integrate recycled materials into their stamping processes. This shift not only minimizes environmental impact but also drives efficiency and cost-effectiveness. Companies are increasingly being held accountable for their carbon footprint, pushing the boundaries of traditional stamping methods to incorporate greener practices. As the market for standard parts for toolmaking is expected to grow from USD 4.1 billion in 2024 to USD 7.6 billion by 2035, with a CAGR of 5.9%, there is a clear trend towards innovation that values both performance and environmental stewardship. This paradigm shift suggests that the future of stamping parts will be defined by those who embrace sustainable practices, transforming manufacturing industries on a global scale.

This chart illustrates the growth trends in sustainable practices within the stamping parts manufacturing industry from 2018 to 2023. The data reflects the increasing investment in eco-friendly technologies and methodologies.

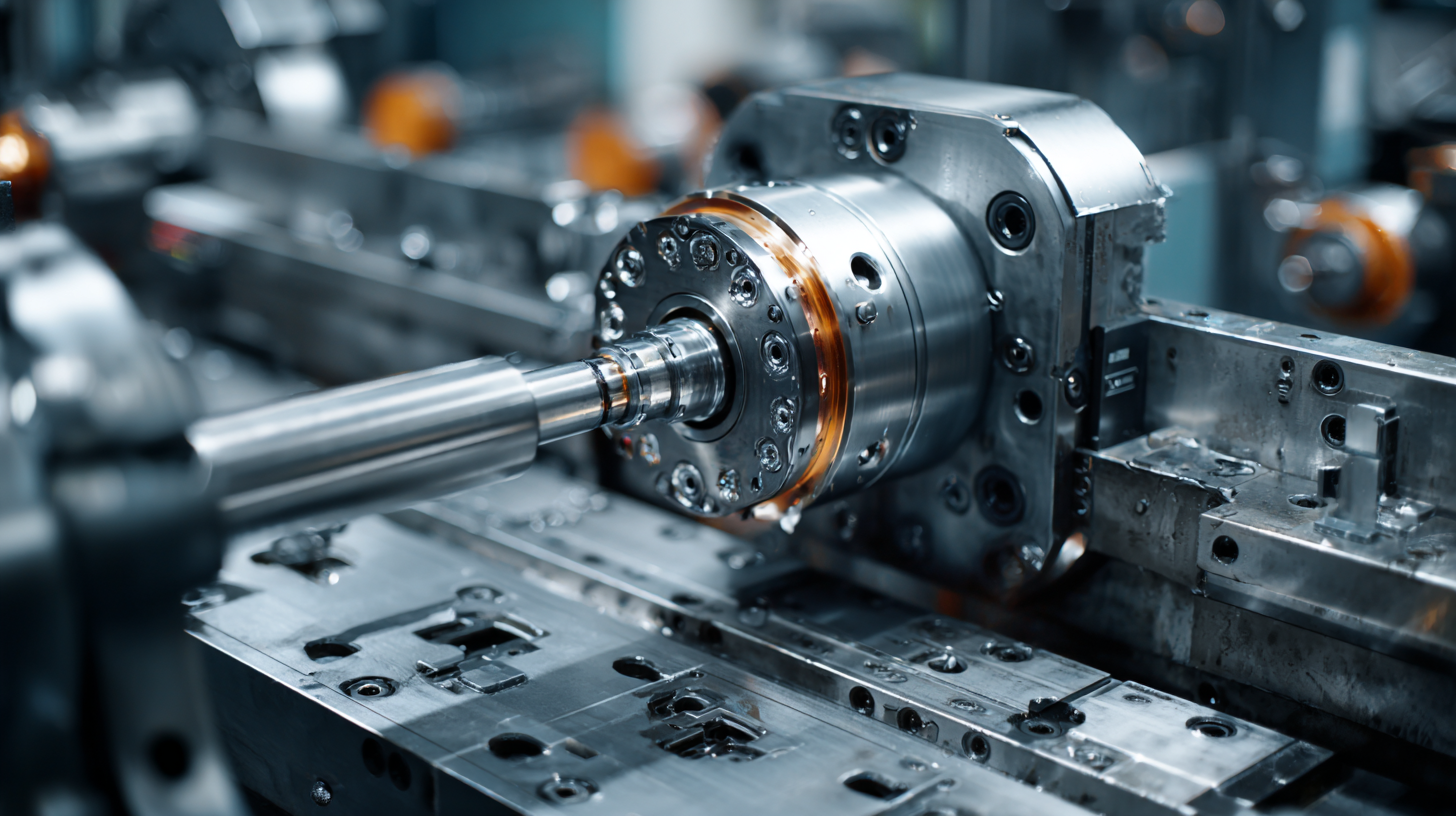

The future of stamping parts in diverse industries is increasingly defined by customization and flexibility. As manufacturers seek to meet the unique demands of their clients, the traditional one-size-fits-all approach is giving way to tailored solutions. Advanced stamping technologies are now capable of producing components that cater to specific applications, enabling industries like automotive, aerospace, and electronics to thrive in a highly competitive market. This shift toward customization not only enhances product quality but also streamlines production processes, reducing lead times and costs.

Moreover, the evolution of stamping methods, including the integration of digital tools and automation, adds another layer of flexibility. Manufacturers can quickly adapt to changing market trends or customer specifications, allowing for smaller batch sizes and less waste. This adaptability not only supports sustainability efforts by minimizing excess material but also enables innovative designs that were previously difficult to achieve. As stamping technology continues to advance, the synergy between customization and flexibility will undoubtedly propel manufacturers into a new era of efficiency and creativity.

Digital twins are set to revolutionize the stamping operations and maintenance within manufacturing industries, providing unprecedented insights and control over production processes. By creating a virtual replica of physical stamping machines, manufacturers can monitor their performance in real-time, allowing for immediate detection of anomalies and predictive maintenance. This innovation minimizes downtime and extends the lifespan of equipment, ultimately enhancing overall productivity and reducing operational costs.

Digital twins are set to revolutionize the stamping operations and maintenance within manufacturing industries, providing unprecedented insights and control over production processes. By creating a virtual replica of physical stamping machines, manufacturers can monitor their performance in real-time, allowing for immediate detection of anomalies and predictive maintenance. This innovation minimizes downtime and extends the lifespan of equipment, ultimately enhancing overall productivity and reducing operational costs.

Furthermore, the integration of digital twins facilitates a more robust data analysis framework. Manufacturers can simulate various scenarios, optimizing stamping operations based on changing demands or material variations without disrupting actual production lines. The ability to test and refine processes in a virtual environment empowers organizations to innovate continuously, ensuring they remain competitive in an ever-evolving market. As the industry embraces these technologies, the shift toward smart manufacturing becomes inevitable, paving the way for more efficient and sustainable practices in stamping operations.