In recent years, the global demand for precision manufacturing has surged, with CNC machining emerging as a cornerstone of modern production processes. According to a report by MarketsandMarkets, the CNC machining market is projected to reach USD 100 billion by 2026, expanding at a CAGR of 6.2% from 2021. This growth is driven by the increasing need for high-quality, efficient, and reliable manufacturing solutions across various industries including automotive, aerospace, and electronics. A leading Chinese factory is stepping up to meet this demand, exemplifying the slogan "中国制造,全球共享,品质值得信赖" – underscoring a commitment to global quality standards. As these manufacturers leverage advanced CNC machining technologies, they not only enhance production capabilities but also ensure the export of high-quality components worldwide, positioning China as a pivotal player in the global manufacturing landscape.

When exploring the world of high-quality CNC machining, especially from a leading Chinese factory, it is vital to understand the technical specifications that define these products. Precision is paramount in CNC machining, which utilizes computer-controlled processes to produce intricate components with tight tolerances. Specifications such as material type, finishing processes, and dimensional accuracy directly affect the performance and durability of the final products. Factories that adhere to internationally recognized standards often leverage advanced technology to ensure that every cycle of production meets stringent quality controls.

Tips: When selecting CNC machining services, always inquire about the materials used and their compatibility with your project requirements. Additionally, consider their quality certifications, such as ISO 9001, which can be indicative of a factory's commitment to maintaining high standards. Don’t hesitate to request sample parts, as they can provide insight into the factory's machining capabilities and attention to detail.

Moreover, understanding the finishing processes is equally crucial. A high-quality CNC part may undergo various finishing treatments such as anodizing, polishing, or coating to enhance properties like corrosion resistance or surface smoothness. Each process has its own set of specifications, impacting not just aesthetics but also performance over time.

Tips: Evaluate the finishing options offered by the manufacturer and ask for data sheets that detail the expected results. This information can help you make informed decisions and ensure that the end products align perfectly with your quality and performance expectations.

The adoption of advanced digital manufacturing technologies in CNC machining has revolutionized productivity across various industries. Leading Chinese CNC machining factories have leveraged these innovations, resulting in significant reductions in lead time and increased precision in manufacturing processes. Reports indicate that the integration of automation and real-time data analytics can enhance production efficiency by over 30%, allowing manufacturers to respond swiftly to market demands while maintaining high-quality standards.

Furthermore, partnering with a top-tier Chinese CNC machining factory provides key advantages, such as cost-effectiveness and access to a skilled workforce. The labor cost advantage, combined with cutting-edge technology, allows for competitive pricing without sacrificing quality. According to industry analyses, manufacturers can achieve up to 20% lower production costs when outsourcing to leading CNC machining providers in China. This strategic approach not only helps businesses improve their bottom line but also positions them to scale operations effectively in today's rapidly changing global market.

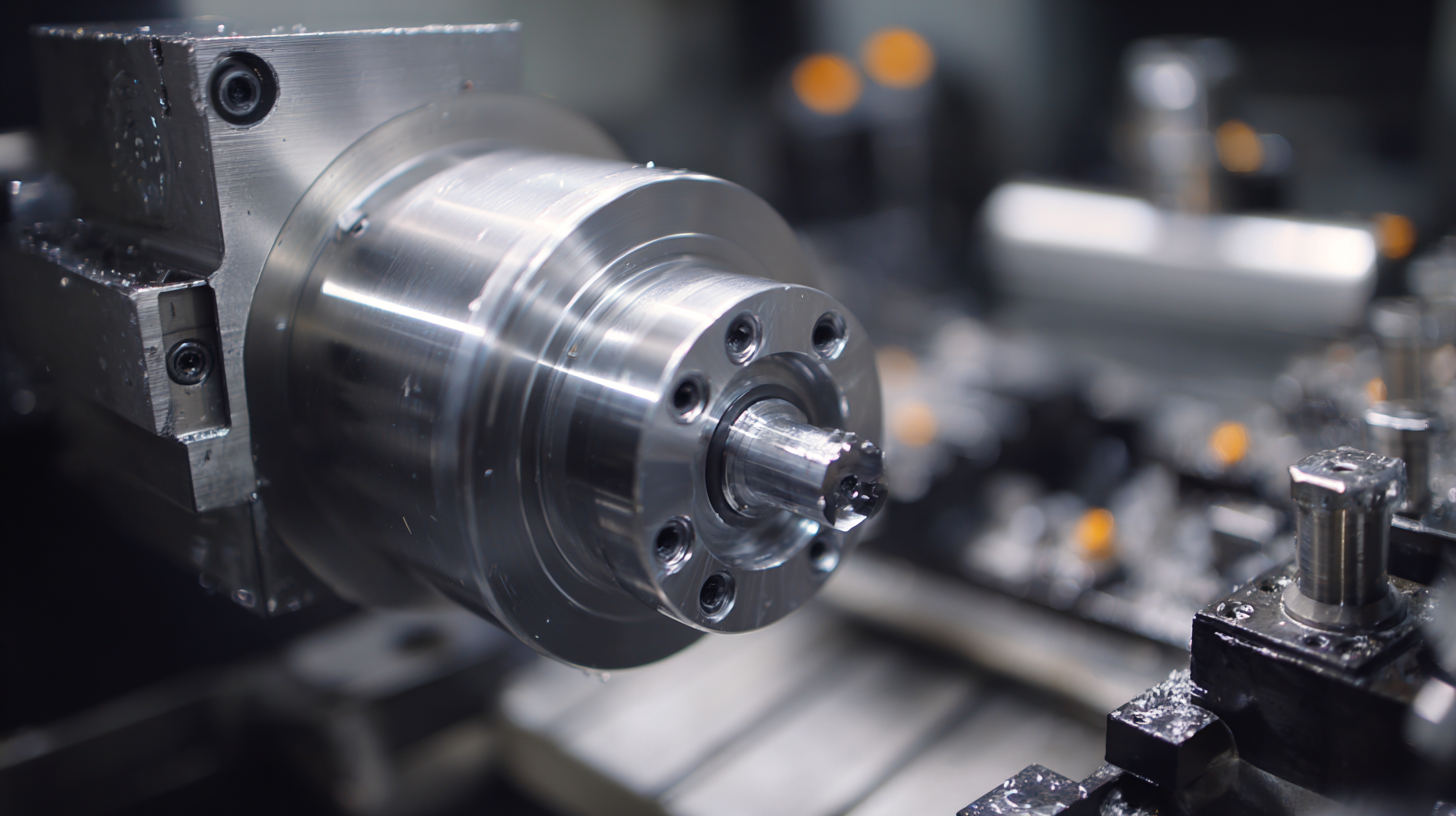

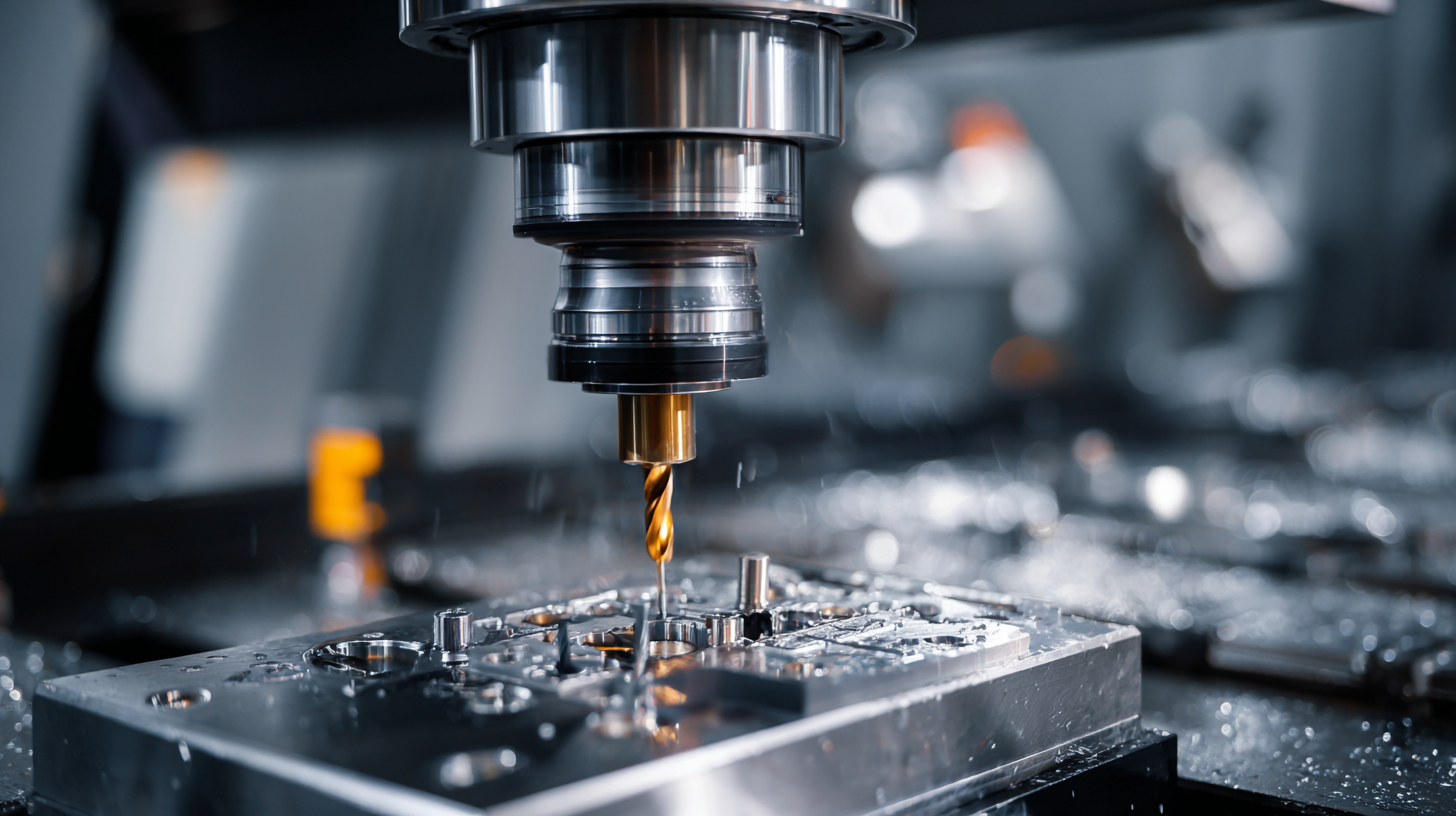

CNC machining has revolutionized the manufacturing industry by offering unparalleled precision and efficiency. The process begins with design, where CAD (Computer-Aided Design) software is used to create a digital blueprint of the part. According to data from MarketsandMarkets, the global CNC machining market is expected to reach $100 billion by 2026, driven by advancements in technology and increasing demand for high-quality components in various sectors.

Once the design is finalized, the CNC machine is programmed using G-code, which instructs the machine on the movements and operations required to shape the material. This step is crucial as it directly impacts the precision of the final product. Industry reports indicate that this level of control allows factories to achieve tolerances as tight as ±0.005 inches, significantly enhancing product quality. The machining process continues with the selection of appropriate materials and tools, ensuring that each component meets the specific requirements of the project.

With the rapid growth in automation, the efficiency of CNC machining processes continues to improve. According to a study by Grand View Research, increased automation in CNC machining is projected to reduce manufacturing times and operational costs by up to 30%. This not only boosts production rates but also enhances the competitiveness of leading manufacturers in China and worldwide, positioning them as key players in the global market for high-quality CNC machined components.

This bar chart illustrates the export volumes of high quality CNC machining parts from various regions in 2023. The data reflects the increasing demand for precision machining in several industries.

The global CNC machining market is poised for significant growth, with projections indicating an increase from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a robust compound annual growth rate of 9.9%. As this market expands, ensuring quality control in CNC machining exports becomes paramount, particularly for manufacturers in China looking to establish themselves as industry leaders. Quality control measures must be integrated at every stage of the manufacturing process, from raw material selection to final product inspection, ensuring that exported goods not only meet but exceed international standards.

Adopting advanced technologies and methodologies is essential for effective quality control. Companies should invest in automated inspection systems that leverage artificial intelligence to detect defects early in production, reducing waste and enhancing efficiency. Additionally, fostering a culture of continuous improvement among employees can drive a commitment to quality at all levels of the organization. By prioritizing rigorous quality control processes, manufacturers can gain a competitive edge in the global market, ultimately contributing to the high-quality development of the CNC machining sector as a whole.

The global market for CNC machining solutions is witnessing substantial growth, driven by increasing demand across various industries. The CNC controller market, for instance, is expected to expand from approximately $33.67 million in 2025 to around $228.7 million by 2033, reflecting a consistent compound annual growth rate (CAGR) of 2.2%. This trend highlights the rising need for precision in manufacturing processes, which CNC technologies are well-equipped to provide.

In parallel, the overall machine tool market is projected to grow from $129.2 billion in 2025 to an impressive $230.42 billion by 2033, indicating a robust CAGR of 7.5% during the forecast period. This growth is largely attributed to advancements in machining capabilities and the increasing adoption of automation technologies, which enhance production efficiency and reduce operational costs. As manufacturers seek to improve throughput and quality, high-quality CNC machining solutions will play a pivotal role in meeting these evolving market demands.