In recent years, the global export landscape for metal stamping has witnessed a remarkable transformation, particularly driven by the robust capabilities of Chinese factories. According to industry reports, China has dominated the metal stamping sector, with exports reaching over $70 billion in 2022, signifying a year-on-year growth of approximately 15%. This uptick can be attributed to the integration of advanced manufacturing technologies and stringent quality control measures that enhance the efficiency and precision of production. Furthermore, the increasing demand for metal stamping components in various sectors—such as automotive, electronics, and aerospace—underscores the necessity for gaining the right export certifications. Understanding the intricacies of these certifications not only streamlines the export process but also grants companies a competitive edge in the international market. As businesses look to expand their reach globally, recognizing these trends in metal stamping will be crucial for success.

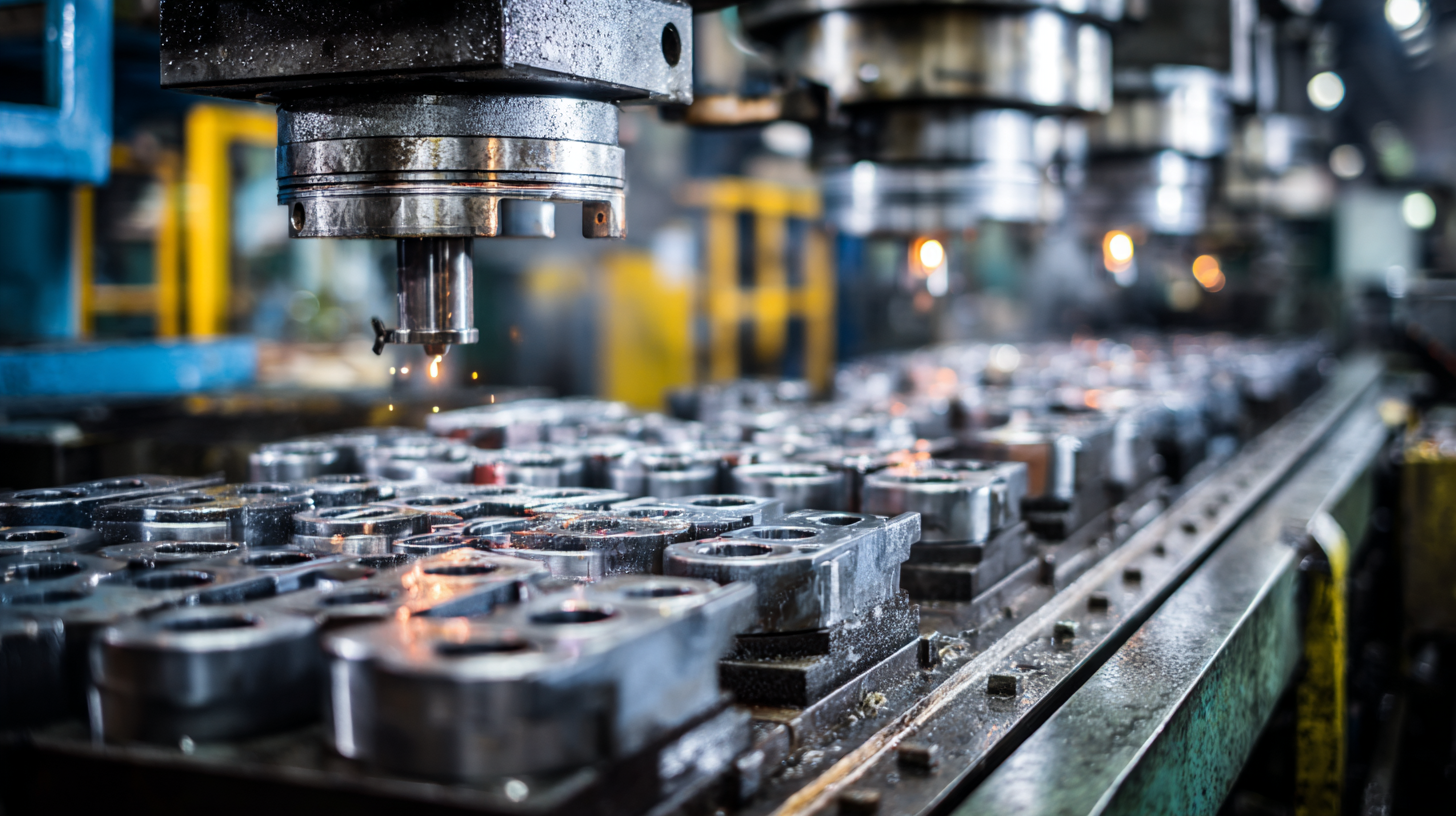

China's metal stamping industry has emerged as a formidable player in the global markets, offering distinct advantages that set it apart from competitors. One significant benefit is the scale of production capabilities. Chinese factories are equipped with state-of-the-art machinery and technologies that allow for mass production and efficiency. This not only reduces costs but also ensures a rapid turnaround time for clients, making it an attractive option for businesses around the world.

Tip: When partnering with a metal stamping manufacturer, be sure to assess their production facilities and technology. High-quality machinery is crucial for consistent output and product reliability.

Moreover, the expertise and skilled workforce in China contribute to high-quality standards in metal stamping processes. With a rich history in manufacturing and a strong emphasis on research and development, these factories are at the forefront of innovation. This results in superior product offerings that meet the diverse needs of global clientele.

Tip: Consider manufacturers that prioritize R&D and innovation in their operations. This focus can lead to better customization options and more advanced stamping techniques that benefit your projects.

This chart illustrates the export volume of metal stamping products from Chinese factories to various global markets. The data reflects the strong export capability and competitive edge of China's metal stamping industry in the international market.

The global metal stamping industry has witnessed unprecedented growth, largely fueled by the robust production capabilities of leading Chinese factories. According to a report by Research and Markets, China accounted for approximately 30% of the world's metal stamping market in 2022, with a remarkable production volume exceeding 8 million metric tons. This significant output underscores China’s dominance in the sector, attributable to its advanced technologies and efficient manufacturing processes.

In addition to high volume, these Chinese factories have embraced innovation, enhancing the quality and precision of their metal stamping products. For instance, the use of automated stamping machines has increased productivity by over 25% in recent years. Furthermore, the value of exported metal stamping products from China reached an impressive USD 15 billion in 2023, signifying a strong demand in global markets. As industries continue to seek cost-effective and high-quality metal components, the statistics firmly place Chinese factories at the forefront of the metal stamping sector.

| Country | Production Volume (tons) | Export Volume (tons) | Market Share (%) | Average Price per Ton ($) |

|---|---|---|---|---|

| China | 500,000 | 200,000 | 35 | 800 |

| USA | 300,000 | 120,000 | 25 | 900 |

| Germany | 250,000 | 80,000 | 20 | 1000 |

| Japan | 200,000 | 60,000 | 15 | 950 |

| South Korea | 150,000 | 50,000 | 10 | 850 |

In the competitive landscape of global manufacturing, advanced technology has emerged as a game-changer in the metal stamping industry. Chinese factories have taken significant strides in integrating state-of-the-art machinery and software into their production processes. This technological infusion enhances precision, reduces waste, and accelerates production speeds, allowing manufacturers to meet the increasing demands of international markets. By leveraging computer numerical control (CNC) systems and automated stamping processes, these factories not only improve the quality of their metal products but also drive down costs, making them formidable players on the global stage.

Moreover, the application of cutting-edge technologies such as artificial intelligence and machine learning in quality control has revolutionized the metal stamping sector. These systems are capable of real-time monitoring, ensuring that any deviations from product specifications are detected and corrected immediately. This not only boosts overall product quality but also instills confidence in clients who prioritize reliability and excellence in their supply chains. As Chinese factories continue to adopt these advancements, their ability to deliver superior metal stamping solutions will solidify their reputation as leaders in global exports.

Sourcing metal stamping from China has proven to be a cost-effective strategy for manufacturers worldwide. According to a report by Smithers Pira, the global metal stamping market is projected to reach $200 billion by 2025, with Asia-Pacific holding a significant share, primarily driven by China’s manufacturing capabilities. Chinese factories benefit from advanced automation technologies, skilled labor, and economies of scale, which collectively reduce production costs by approximately 20-30% compared to manufacturers in North America and Europe.

Furthermore, a study by Deloitte highlights that companies sourcing metal products from China can achieve a substantial reduction in their total landed costs. The report indicates that sourcing from China can not only save on direct manufacturing costs but also help mitigate shipping expenses due to the country’s well-established logistics infrastructure. For instance, the average ocean freight costs from China to the U.S. have decreased by 15% over the past few years, making it easier for companies to maintain competitive pricing while ensuring high-quality metal stamping components. As such, leveraging China's robust manufacturing environment continues to be a strategic move for businesses aiming to optimize their supply chains and enhance profitability.

The global metal stamping market is poised for significant growth, reflecting the rising demand across various industries, particularly in automotive and consumer goods. As we navigate through evolving market trends, projections indicate that the market revenue will surge from USD 223.68 billion in 2025 to an estimated USD 312.32 billion by 2033, signifying an impressive increase driven by technological advancements and production efficiency. This growth trajectory, with a projected rise of USD 40.18 billion between 2023 and 2028, illustrates a robust annual growth rate, highlighting the sector's resilience.

The global metal stamping market is poised for significant growth, reflecting the rising demand across various industries, particularly in automotive and consumer goods. As we navigate through evolving market trends, projections indicate that the market revenue will surge from USD 223.68 billion in 2025 to an estimated USD 312.32 billion by 2033, signifying an impressive increase driven by technological advancements and production efficiency. This growth trajectory, with a projected rise of USD 40.18 billion between 2023 and 2028, illustrates a robust annual growth rate, highlighting the sector's resilience.

China plays a pivotal role in this growth, being home to some of the most powerful factories equipped to meet global demands. These factories leverage advanced manufacturing techniques and scale economies to produce high-quality metal stampings that cater to international markets. As global industries seek reliable suppliers for their stamping needs, China's contribution to the sector becomes increasingly significant, ensuring a steady supply of innovative and cost-effective solutions. The combination of strong demand and China's manufacturing capabilities positions the country as a key player in the global metal stamping landscape.