In the rapidly evolving landscape of manufacturing, understanding die mold components is crucial for engineers and practitioners alike. According to industry expert Dr. Amelia Carter, a renowned figure in mold technology, "The effectiveness of any manufacturing process heavily relies on the quality and design of die mold components." This statement encapsulates the essence of why a deep comprehension of these elements is essential not just for efficiency but also for innovation in production.

As we delve into the intricate world of die mold components, we explore the latest innovations and best practices shaping the industry. From advanced materials to cutting-edge production techniques, these advancements not only enhance the performance of die molds but also contribute to overall cost-effectiveness and sustainability in manufacturing. By integrating state-of-the-art technologies and methodologies, manufacturers can improve their workflows and produce higher-quality products at unprecedented speeds.

This essential guide serves as a comprehensive resource for understanding the multifaceted components of die molds. Whether you are a seasoned expert or new to the field, gaining insights into the innovations and best practices surrounding die mold components will empower you to stay ahead of the curve and drive success in your projects.

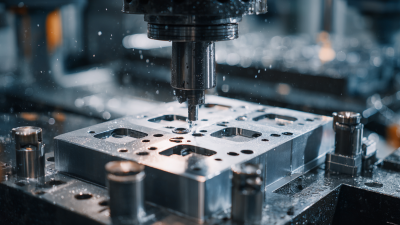

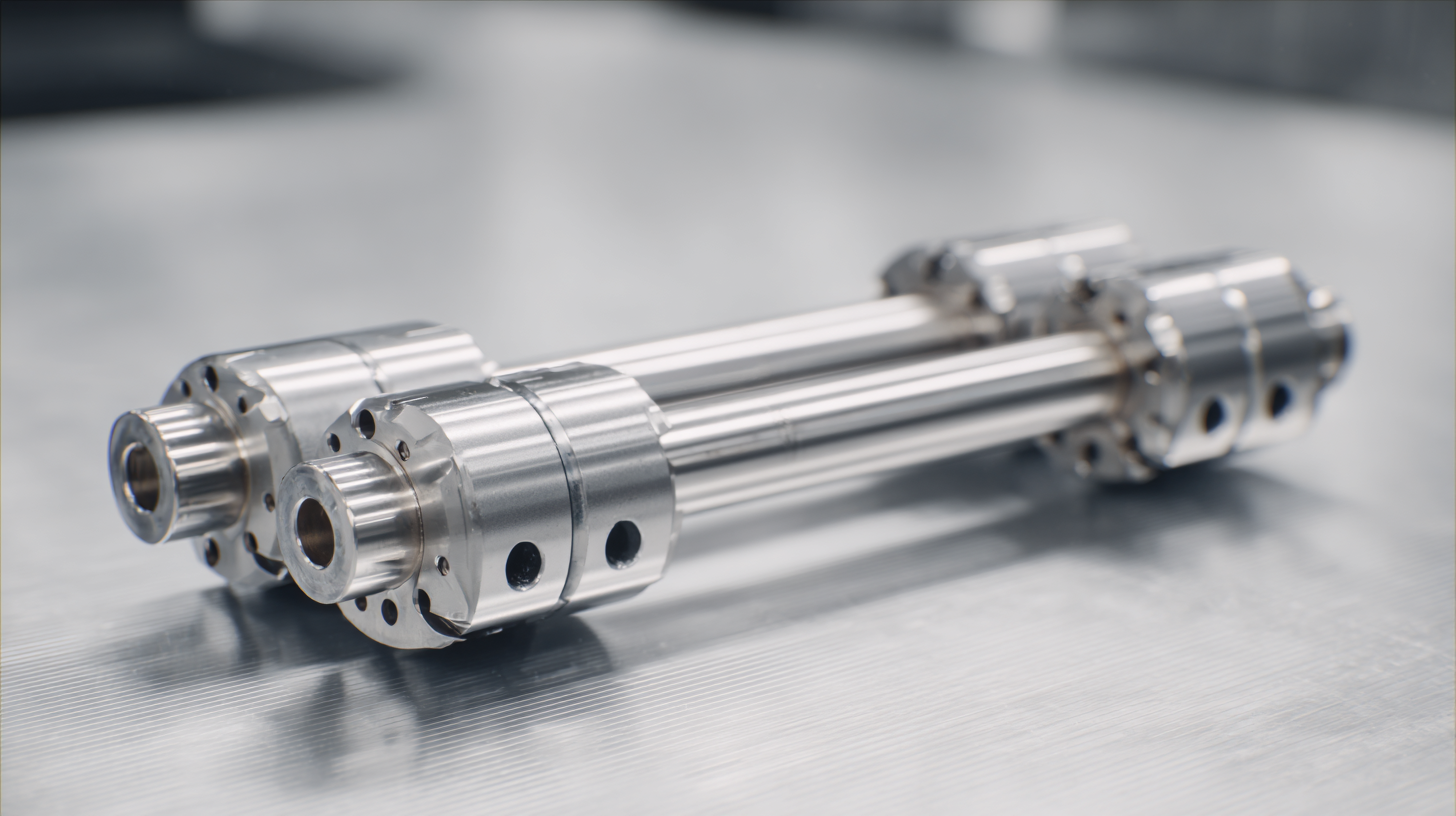

Die molds are critical in the manufacturing process, particularly in injection molding, where precision and efficiency are paramount. Key components of a die mold include the core, cavity, ejector pins, and cooling channels, each playing a vital role in producing high-quality parts. According to a report by MarketsandMarkets, the global mold market is expected to grow significantly, from $24.5 billion in 2021 to over $32 billion by 2026, emphasizing the increasing importance of understanding these components for optimal production output.

Die molds are critical in the manufacturing process, particularly in injection molding, where precision and efficiency are paramount. Key components of a die mold include the core, cavity, ejector pins, and cooling channels, each playing a vital role in producing high-quality parts. According to a report by MarketsandMarkets, the global mold market is expected to grow significantly, from $24.5 billion in 2021 to over $32 billion by 2026, emphasizing the increasing importance of understanding these components for optimal production output.

The core and cavity form the shape of the product, while ejector pins facilitate the removal of the finished part, minimizing defects and cycle times. Cooling channels are particularly critical, as they manage the mold temperature, influencing the solidification process and overall quality of the molded item. Industry data reveals that an efficient cooling system can decrease cycle times by up to 25%, significantly enhancing productivity. Investing in state-of-the-art die mold technology and understanding the function of each component is essential for manufacturers striving for excellence in their production processes.

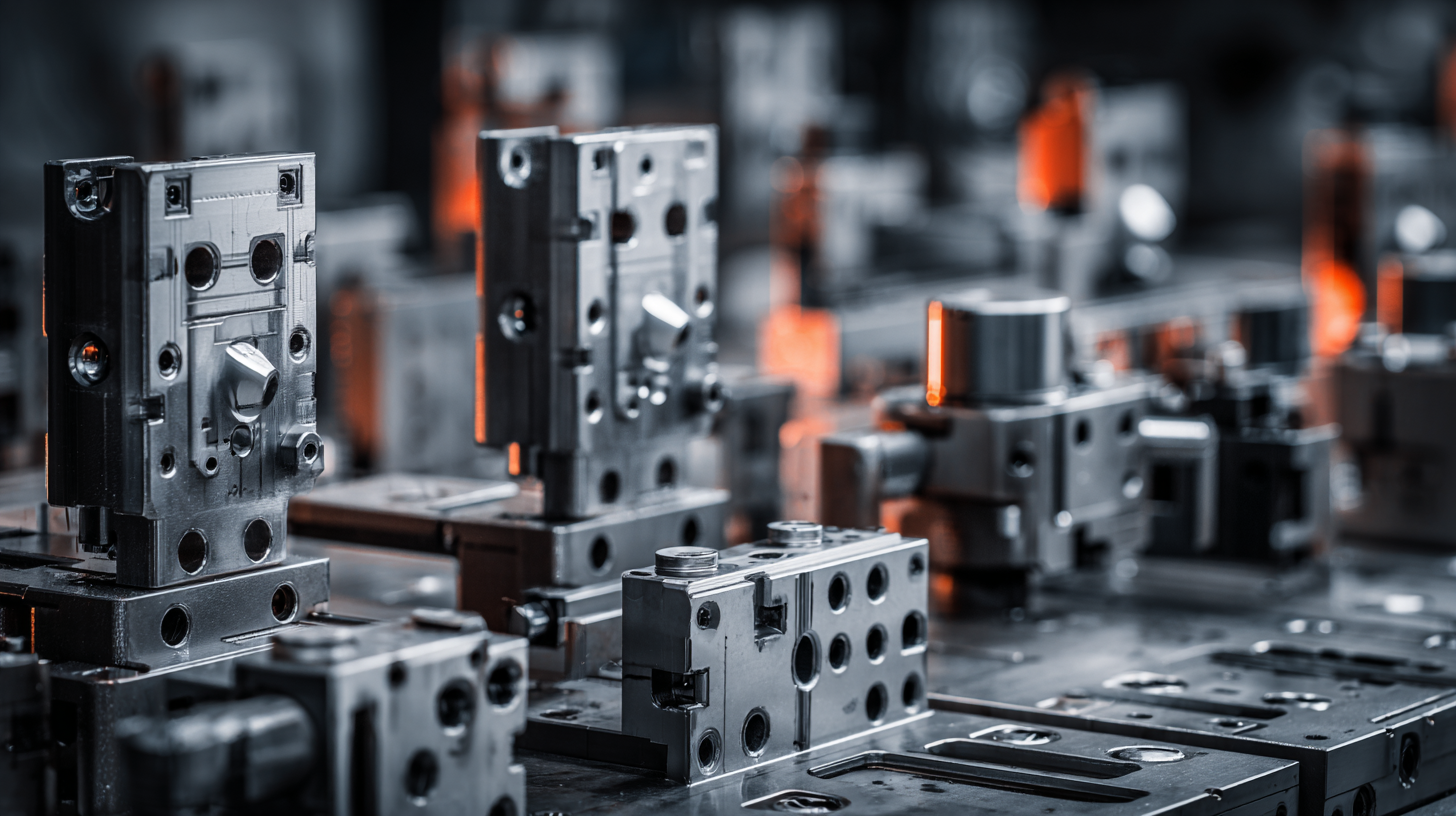

The advancements in materials science have significantly transformed die mold design, leading to enhanced durability and performance. Innovative materials such as high-performance polymers, composite materials, and advanced alloys are now at the forefront of die mold manufacturing. These materials offer superior mechanical properties, such as increased tensile strength and resistance to deformation, which are critical for producing high-quality molded parts. For instance, the use of engineered thermoplastics not only reduces the weight of molds but also improves their thermal stability, which is essential in rapid cooling processes.

Furthermore, the integration of surface treatment technologies has played a vital role in elevating the lifespan of die molds. Techniques such as coating with hard metals or ceramics can enhance wear resistance, reducing the frequency of maintenance and replacement. Additionally, innovations like 3D printing allow for the creation of complex geometries that were previously unattainable with traditional manufacturing methods. This not only helps in optimizing the cooling channels for better temperature control during production but also facilitates quicker design iterations, leading to increased overall efficiency in the molding process. Embracing these innovative materials and techniques is paramount for manufacturers looking to improve their operational capabilities and competitiveness in the market.

Maintaining and caring for die mold components are crucial for ensuring optimal performance and longevity in manufacturing processes. One of the best practices is to establish a regular maintenance schedule. This includes frequent inspection of the components for signs of wear, corrosion, or damage, which can lead to costly downtimes if not addressed promptly. Utilizing advanced monitoring technologies, such as temperature and pressure sensors, can help identify potential issues before they escalate, allowing for timely interventions.

Another vital practice is the use of high-quality lubricants and cleaning agents to protect the molds. Proper lubrication reduces friction and wear, while routine cleaning removes debris and contaminants that can affect the mold’s performance. It’s essential to select the right products specifically designed for the materials used in the molds. Additionally, training personnel in best cleaning techniques and safe handling procedures can significantly enhance the lifespan of die mold components, ensuring that they operate at peak efficiency. By prioritizing maintenance and care, manufacturers can maximize their investment in die mold technology and improve overall productivity.

The die mold manufacturing industry is experiencing a transformative shift driven by emerging technologies that enhance precision, efficiency, and sustainability. One notable trend is the integration of additive manufacturing, which allows for rapid prototyping and the creation of complex geometries that were previously impossible with traditional methods. This technology not only reduces material waste but also shortens lead times, offering manufacturers a competitive edge in a fast-paced market.

Another significant development is the implementation of automation and robotics within the die mold production process. These innovations streamline operations and reduce human error, leading to higher quality outputs. Moreover, advanced analytics and AI are being utilized to predict maintenance needs and optimize production workflows, enabling manufacturers to respond more agilely to changing market demands. As these technologies continue to evolve, they are set to define the future landscape of die mold manufacturing, pushing the boundaries of what is achievable in the industry.

In the die mold industry, safety considerations are paramount to ensure effective risk management and regulatory compliance. According to a report by the Occupational Safety and Health Administration (OSHA), approximately 36,000 injuries occur annually in manufacturing facilities, with a significant portion attributable to improper die mold operations. Implementing robust safety protocols can mitigate these risks, safeguarding both employees and machinery.

Moreover, the introduction of advanced safety technologies has transformed die mold operations. For instance, the integration of machine learning algorithms allows for predictive maintenance, which can forecast potential equipment failures before they occur. A study from the National Institute of Standards and Technology (NIST) suggests that manufacturers adopting such technologies have reported a 25% reduction in workplace accidents. Ensuring compliance with guidelines outlined by organizations like the American National Standards Institute (ANSI) is essential, as adherence not only protects workers but also enhances the overall efficiency of die mold operations.