In today's manufacturing landscape, the demand for precision and efficiency has never been greater, particularly in the realm of punching mould manufacture. According to a report by Mordor Intelligence, the global mould manufacturing market is projected to grow from $18 billion in 2021 to over $24 billion by 2026, driven by advancements in automation and the rising need for custom-shaped components across various industries. As businesses increasingly rely on high-quality moulds for production, selecting the right punching mould manufacturer becomes crucial to ensure that products meet rigorous standards.

In today's manufacturing landscape, the demand for precision and efficiency has never been greater, particularly in the realm of punching mould manufacture. According to a report by Mordor Intelligence, the global mould manufacturing market is projected to grow from $18 billion in 2021 to over $24 billion by 2026, driven by advancements in automation and the rising need for custom-shaped components across various industries. As businesses increasingly rely on high-quality moulds for production, selecting the right punching mould manufacturer becomes crucial to ensure that products meet rigorous standards.

This essential guide will delve into the critical aspects of sourcing the best punching mould manufacture, offering insights and strategies to help businesses navigate this intricate process effectively. Whether you’re a startup or an established corporation, understanding how to identify reliable partners can significantly impact your operational success and bottom line.

When selecting a punching mould manufacturer for your business, several key considerations can significantly impact your final decision. Firstly, evaluate the manufacturer’s experience and expertise in the industry. A company with a proven track record in producing high-quality moulds is more likely to meet your specifications and ensure durability. Inquire about their past projects and request references to gauge their reliability and professionalism.

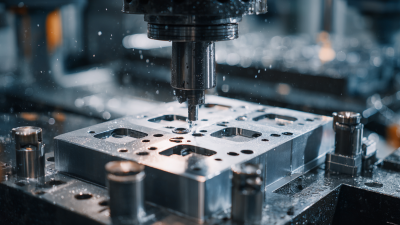

Another crucial aspect to consider is the manufacturer's technological capabilities. The use of advanced machinery and software can greatly enhance the precision and efficiency of the mould-making process. Assess whether the manufacturer invests in research and development, as this reflects their commitment to innovation and quality improvement. Additionally, it’s vital to ensure that the company adheres to industry standards and regulations, as compliance will help prevent future issues related to product quality and safety. By focusing on these considerations, businesses can make an informed choice that aligns with their production needs.

When sourcing the best punching moulds for your business, understanding the key features that contribute to efficiency and quality is crucial. A recent industry report by Smithers indicates that the global die casting market is expected to grow by 5.3% annually, underscoring the increasing demand for high-quality moulds. One of the top features to consider is the material used in the mould construction. High-quality steel or aluminum alloys ensure durability and longevity, which can significantly reduce replacement costs and downtime during production.

Another essential feature is the precision of the mould design. According to a report from Research and Markets, precision-engineered punching moulds can enhance production speeds by up to 30%. This is particularly important in industries where mass production is needed, as the accuracy of the punch can directly impact the quality of the finished products. Furthermore, effective heat treatment processes can improve the wear resistance of moulds, allowing for extended operational life and better performance under high-pressure conditions. Investing in moulds with these critical features can ultimately lead to a more efficient production process and superior end products for your business.

| Feature | Description | Importance | Rating (1-5) |

|---|---|---|---|

| Material Quality | High-quality materials ensure durability and longevity of the mould. | Critical | 5 |

| Customization Options | Ability to customize moulds according to specific business requirements. | High | 4 |

| Lead Time | Time taken to manufacture and deliver the moulds. | High | 4 |

| Technical Support | Availability of technical assistance during and after the mould setup. | Moderate | 3 |

| Cost-Effectiveness | Balancing quality with budget to avoid overspending. | Critical | 4 |

| Reputation & Experience | Proven track record and experience in the industry can influence quality. | High | 5 |

When sourcing the best punching mould manufacturers for your business, asking the right questions is crucial to ensure you partner with a reliable supplier. One essential question is about their production capabilities. According to a 2022 report by the Global Market Insights, the punching mould market is projected to reach $12 billion by 2028, indicating a growing demand for high-quality moulding solutions. Understanding a supplier's production capacity can help you gauge whether they can meet your business needs, especially during peak periods.

Another important question revolves around their quality control measures. The same report emphasizes that 70% of manufacturers fail to consistently maintain quality standards, leading to increased defects and production delays. Inquire about the quality assurance processes, certifications, and the frequency of inspections that the supplier undertakes. This will give you insights into their commitment to producing reliable and durable moulds that meet industry standards and your specific requirements.

When sourcing high-quality punching molds for your business, it's essential to consider the top countries renowned for their manufacturing excellence. Japan remains a powerhouse in the mold and die sector, leveraging its traditional monozukuri craftsmanship alongside innovative technologies. In recent years, however, other countries in the Asia-Pacific region, such as Vietnam, Cambodia, and Indonesia, have emerged as formidable competitors, successfully adopting and adapting Japanese manufacturing processes. This shift highlights the importance of not only quality but also strategic location when selecting a manufacturing partner.

In Europe, Switzerland stands out with its advanced technologies in high-speed precision stamping and punching. Companies in this region are setting benchmarks for quality and efficiency, attracting businesses looking for reliable mold manufacturers. As the market continues to evolve, understanding the strengths of different regions is crucial for making informed sourcing decisions. Whether focusing on tradition or innovation, aligning your manufacturing needs with the right country can significantly impact your product quality and overall business success.

When sourcing a punching mould manufacturer, one of the pivotal decisions you’ll face is choosing between local and overseas suppliers. A 2022 industry report by Market Research Future indicates that 70% of businesses that opted for local manufacturers cited quicker turnaround times and easier communication as significant advantages. In contrast, overseas manufacturers, particularly in Asia, often offer lower production costs due to lower labor expenses. However, these savings can sometimes be offset by longer shipping times and potential language barriers.

Tips: When assessing overseas manufacturers, always request samples to evaluate quality. Additionally, consider visiting the supplier's facility if possible, as this can provide invaluable insights into their operational capabilities.

Furthermore, local manufacturers can be advantageous for businesses needing rapid prototyping or modifications. A survey from the National Association of Manufacturers found that companies working with local suppliers experienced a 30% decrease in lead times. Therefore, if your business thrives on innovation and requires flexibility, local options might suit you best.

Tips: Leverage technology tools for track and trace to monitor production processes, regardless of whether you choose local or overseas partners. This ensures you maintain quality control throughout the manufacturing process.