CNC milling is a vital process in modern manufacturing. It allows for high precision in creating intricate parts. However, achieving consistent accuracy can be challenging. Many factors affect the outcome, including machine calibration, tool selection, and material choice.

Improving CNC milling techniques requires a detailed examination of these aspects. Operators must frequently evaluate the performance of their machines. It’s not enough to rely on the same settings over time. Each project may demand different approaches and adjustments. For instance, using the right tool for the material can lead to better results.

In practice, even minor mistakes can lead to significant errors. Failing to check for tool wear or not adjusting feed rates can compromise precision. Reflecting on these practices improves the overall quality of the manufacturing process. Attention to detail in CNC milling is essential for higher standards and better outcomes.

CNC milling is a crucial process for achieving high precision in manufacturing. Understanding its basics can significantly enhance the quality of the final product. Precision is not just a goal; it's a necessity in industries like aerospace and automotive. Reports indicate that over 30% of machining failures stem from poor milling techniques. This highlights the urgency for improvement.

Tools play a vital role in CNC milling. The choice of cutting tools can dramatically affect precision. For instance, utilizing tungsten carbide tools can increase tool life by up to 50%. However, many shops still rely on outdated tools, leading to inconsistencies. A study shows that 25% of shops do not regularly assess their equipment, risking accuracy in production.

Machine calibration is often overlooked yet is essential for precision. Inaccurate setups can cause dimensional errors of up to 0.5 mm, which may seem small but can lead to significant issues in assembly. Regular recalibration should be a fundamental part of maintenance protocols. Surprisingly, around 40% of manufacturers do not follow a consistent calibration schedule. Improving awareness in this area could lead to better overall outcomes in precision manufacturing.

This chart illustrates the impact of various parameters on the precision of CNC milling techniques. Higher RPM and optimized feed rates contribute significantly to improved precision, while factors such as tool diameter and material hardness also play crucial roles.

CNC milling is vital for precision manufacturing. However, various challenges can undermine accuracy. Some common issues include tool wear, improper setup, and vibrations. Tool wear can lead to dimensions drifting over time. Regular inspections of tools are essential. If tools are not sharp, results may suffer.

Improper setup of the workpiece affects precision. A misaligned piece can lead to errors in dimension and finish. It’s crucial to double-check fixtures. Investing time in setup can save significant rework later. Remember, a minute alteration in setup can amplify errors.

Vibrations during the milling process can disrupt finishes. These disturbances may stem from the machine, tools, or even surrounding equipment. Using rigid setups and dampening materials helps. Pay attention to spindle speeds and feed rates. Sometimes, an attempt to push speeds leads to more significant problems. Fine-tuning variables may help achieve better results.

Selecting the right tools and machinery is crucial for improving CNC milling precision. The choice of milling machines impacts accuracy significantly. High-quality machines often provide better stability and reduced vibration. A robust base and powerful spindle are essentials. Look for tools that offer precise control of feed rates and cutting depths.

Different materials require different tools. For hard materials, carbide end mills may work best. They offer durability and precision, yet can be costly. Sometimes, high-speed steel tools suffice. They are versatile but may wear faster. It's essential to evaluate the material used and adjust selections accordingly.

Calibration of equipment is another overlooked aspect. Regular checks can prevent unforeseen discrepancies. If a tool is blunt, it will lead to poor finishes. Balancing tools and workpieces correctly ensures uniform cuts. A small mistake in setup can cause greater issues later. Consistent reflection on equipment performance leads to continuous improvement in techniques.

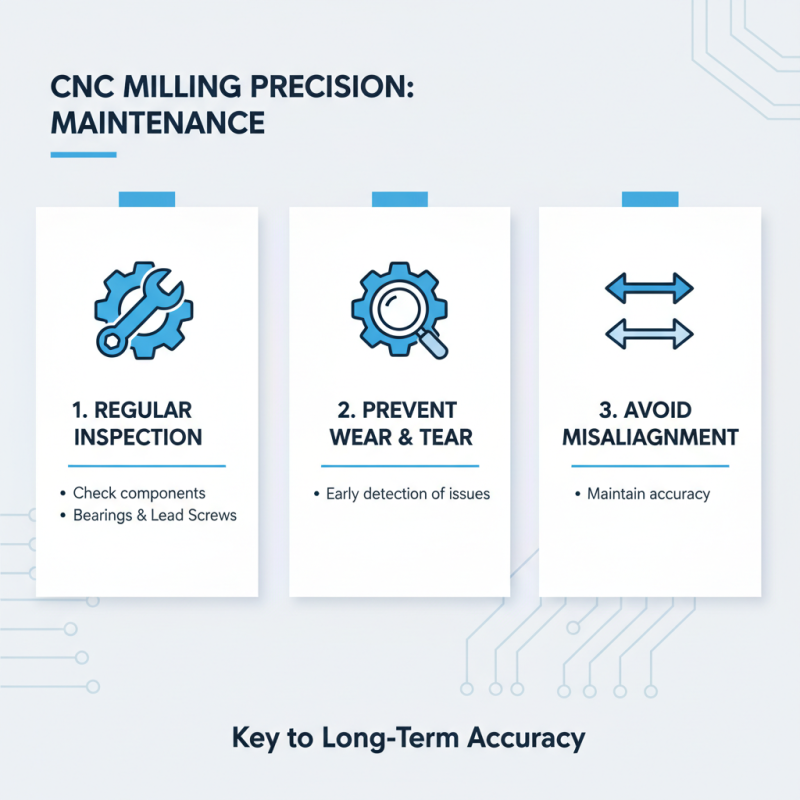

To enhance CNC milling precision, maintenance practices play a crucial role. Regular inspection of the machinery is essential. Check for wear and tear on components like bearings and lead screws. Slight misalignments can lead to significant errors over time. A vigilant eye can catch these issues early.

Tips for maintaining your CNC mill include cleaning the machine regularly. Dust and debris can affect the machining process. Ensure coolant systems function properly to prevent overheating. Neglecting these tasks can result in diminished accuracy.

Another critical aspect is calibrating your CNC machine often. Over time, machines can drift from their original settings. Fine-tuning the settings can correct this drift. Sometimes, it feels tedious, but it pays off in the long run. Regular adjustments lead to better results. Remember, every little detail counts in achieving high precision.

CNC milling has advanced significantly, driven by software solutions that enhance precision. Advanced software can analyze milling strategy and optimize tool paths. According to a recent industry report, using these tools can improve machining accuracy by up to 25%. The integration of real-time monitoring systems further refines this process. Accurate data capture helps in adjusting parameters on-the-fly, ensuring fewer errors in the final product.

Tips: Invest time in training staff on software capabilities. A skilled operator can leverage these tools effectively. Regularly review the software updates; outdated systems may hinder performance.

Despite these advancements, challenges remain. Operators might struggle to understand complex software interfaces. Moreover, the reliance on automated systems can lead to complacency. If the operator does not manually check key parameters, mistakes can still occur. Regular audits are crucial to ensure the systems work as intended.

Tips: Set up periodic training refreshers to keep skills sharp. Encourage operators to engage with the software, asking questions and offering feedback. Collaboration can bridge the gap between technology and experience.