The 138th Canton Fair in 2025 serves as a pivotal platform for showcasing the latest advancements in various industries, with a particular emphasis on innovations in metal mold manufacturing. As global demand for precision and efficiency in manufacturing processes rises, metal mold manufacturers are stepping up to demonstrate cutting-edge technologies and methodologies that redefine production standards. This year’s fair promises to highlight pioneering techniques, sustainable practices, and high-performance materials utilized in the creation of molds, catering to a wide array of sectors including automotive, electronics, and consumer goods.

Attendees will have the unique opportunity to engage with leading metal mold manufacturers, discover emerging trends, and explore future-ready solutions that could well shape the manufacturing landscape in the years to come. As participants gather to exchange insights and foster collaborations, the fair underscores the critical role of innovation in enhancing competitiveness within the global marketplace.

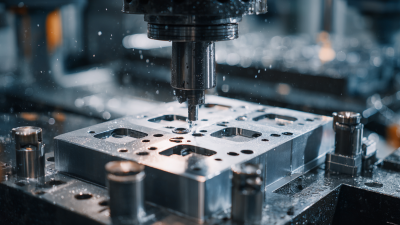

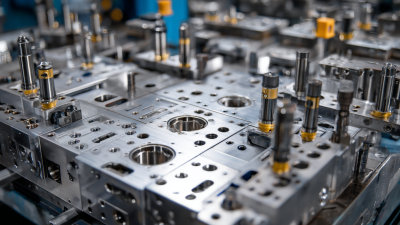

The 138th Canton Fair in 2025 showcased a remarkable array of innovations in metal mold technology, reflecting the industry's evolving landscape. Exhibitors presented cutting-edge advancements that cater to the growing demand for precision and efficiency in manufacturing processes. Notably, the introduction of smart molds equipped with IoT capabilities allows for real-time monitoring and adjustments, significantly enhancing production accuracy and reducing waste. This integration of technology not only streamlines the manufacturing workflow but also opens up new possibilities for customization, enabling businesses to tailor solutions that meet specific customer needs.

Another prominent trend highlighted at the fair was the shift towards sustainable practices in metal mold manufacturing. Companies are increasingly adopting eco-friendly materials and processes, such as the use of recycled metals and energy-efficient production techniques. This commitment to sustainability not only aligns with global environmental standards but also resonates with the values of today’s consumers, making it a competitive advantage. As the fair concluded, it was evident that these innovations are setting the stage for a transformative era in metal mold technology, where efficiency, customization, and sustainability are at the forefront of industry advancements.

At the upcoming 138th Canton Fair in 2025, metal mold manufacturing will take center stage, showcasing cutting-edge innovations from key exhibitors leading the charge in the industry. This event serves as a significant platform for highlighting advancements such as sustainable practices, automation, and precision engineering that are transforming traditional manufacturing processes. Attendees can expect to see new methodologies that improve efficiency while reducing environmental impact, aligning with global trends toward green manufacturing.

Tips: When attending such expos, focus on networking opportunities with thought leaders and innovators in the field. Engaging with exhibitors who are pioneering new technologies can provide valuable insights into future market trends.

Additionally, take note of the seminars and workshops offered during the fair. These sessions often feature industry experts discussing the latest advancements and best practices, allowing participants to gain firsthand knowledge that can drive their own business strategies forward.

The 138th Canton Fair in 2025 is set to be a significant platform for showcasing sustainable practices in metal mold manufacturing. As the industry grapples with environmental challenges, innovations such as eco-friendly materials and energy-efficient production techniques are gaining traction. According to a report by the International Metalworking Federation, around 25% of metal mold manufacturers are now adopting sustainable practices, significantly reducing their carbon footprints. This shift not only benefits the environment but also enhances operational efficiencies, leading to cost savings for manufacturers.

Moreover, the use of biodegradable polymers and recycled metals is on the rise. A recent study indicated that integrating recycled materials into mold production can reduce energy consumption by up to 30%. This is a crucial step towards a circular economy within the metalworking sector. Attendees at the Canton Fair can expect to see cutting-edge innovations that prioritize sustainability, sparking discussions on future industry standards.

Tips: When exploring sustainable options, consider evaluating your current suppliers for their commitment to eco-friendly practices. Additionally, invest in training your workforce on sustainable techniques to maximize the benefits of your initiatives. Networking at events like the Canton Fair can also help you discover new technologies that align with your sustainability goals.

The 138th Canton Fair in 2025 promises to be a significant platform for industry professionals in the metal mold sector, offering abundant networking opportunities. As the demand for innovative manufacturing techniques intensifies, professionals can connect with peers and stakeholders to exchange ideas and foster partnerships. The fair will feature advancements in metal mold manufacturing processes, emphasizing collaborative efforts that drive the industry forward.

Given the recent trends in metal injection molding, particularly its robust application in the medical sector, attendees will gain insights into emerging technologies that enhance product quality and efficiency. Events like these provide a unique chance for professionals to delve into discussions around market challenges, including the effects of tariffs on commodity markets, while also exploring how these challenges can create new manufacturing prospects. By participating in the Canton Fair, industry members can leverage these interactions to stay at the forefront of innovation and growth within the metal mold landscape.

The evolution of metal mold manufacturing is being significantly shaped by innovations showcased at events like the 138th Canton Fair 2025. As industries increasingly turn to automation and advanced manufacturing technologies, the demand for precision and efficiency in metal mold production is expected to surge. Reports indicate that the global precision metal stamping market is projected to grow to $33.5 billion by 2026, driven by advancements in manufacturing technologies and emerging applications across various sectors.

At the Canton Fair, manufacturers will focus on integrating new technologies that enhance production efficiency and reduce waste. This aligns with trends seen at other manufacturing exhibitions, such as EMO Hannover 2025, which emphasizes automation's role in driving innovation. To stay competitive, mold manufacturers must adopt smart manufacturing practices, leveraging data analytics and AI to optimize processes and product quality.

**Tips:** Embracing sustainable practices can further elevate a company's market position. Investing in energy-efficient machinery and biodegradable materials not only complies with regulatory standards but also appeals to environmentally conscious consumers. Additionally, fostering partnerships with tech firms can facilitate the integration of IoT and robotics, enabling manufacturers to streamline their operations and respond swiftly to market demands.

| Innovation Category | Description | Impact on Industry | Future Trends |

|---|---|---|---|

| 3D Printing in Metal Molds | Utilizing additive manufacturing to create complex mold geometries. | Increased design flexibility and reduced lead times for mold production. | Growth in applications across automotive and aerospace industries. |

| Smart Mold Technologies | Integration of IoT sensors for real-time monitoring of mold performance. | Enhanced efficiency and predictive maintenance capabilities. | Shift towards fully automated manufacturing processes. |

| Sustainable Materials | Use of eco-friendly materials in mold manufacturing. | Reduction in environmental impact and compliance with regulations. | Increased focus on circular economy principles. |

| Simulation Software | Advanced simulation tools for mold testing and optimization. | Minimized errors in mold design and reduced production costs. | Widespread adoption in training for mold design engineers. |

| Robotics in Molding Processes | Deployment of robotic arms for precision handling of molds. | Improved production speed and worker safety. | Automation trends leading to decreased labor costs. |