The landscape of modern industries is undergoing a significant transformation, largely propelled by innovative fabrication services that enhance productivity and efficiency across various sectors. According to a recent report by MarketsandMarkets, the global fabrication services market is predicted to reach $30 billion by 2025, driven by increasing demand for custom parts and products tailored to specific applications.

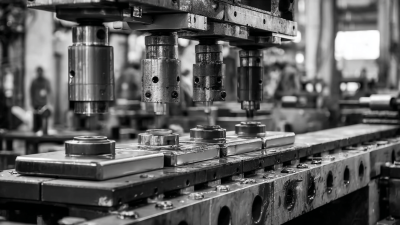

Industries including aerospace, automotive, and healthcare are leveraging advanced fabrication techniques such as additive manufacturing and CNC machining to create more complex designs while minimizing waste and production costs. As these technological advancements continue to unfold, businesses that embrace cutting-edge fabrication services set themselves apart, gaining a competitive edge in the increasingly dynamic market.

This blog delves into how these transformative services are reshaping industries and the implications for future innovations.

Innovative fabrication techniques are redefining traditional manufacturing, aligning with the concept of new quality productivity that emphasizes technological innovation as the primary driver of development. This shift is pivotal for industries aiming to deepen their integration with advanced technology, leading to enhanced production capabilities and overall efficiency. As the concept of new quality productivity gains traction, manufacturing sectors are called to adopt modernization strategies that leverage breakthroughs in digital technology, such as big data and artificial intelligence.

Innovative fabrication techniques are redefining traditional manufacturing, aligning with the concept of new quality productivity that emphasizes technological innovation as the primary driver of development. This shift is pivotal for industries aiming to deepen their integration with advanced technology, leading to enhanced production capabilities and overall efficiency. As the concept of new quality productivity gains traction, manufacturing sectors are called to adopt modernization strategies that leverage breakthroughs in digital technology, such as big data and artificial intelligence.

Tips: Explore how incorporating automation and smart technologies can optimize production processes and reduce operational costs. Industries should prioritize investing in R&D to foster innovation that not only improves productivity but also drives sustainability.

The pursuit of new quality productivity reflects a broader commitment to high-quality development that is essential in today’s rapidly changing economic landscape. This transformation is crucial for traditional industries seeking to maintain relevance and competitiveness. By embracing innovative fabrication services, these sectors can navigate the complexities of the modern manufacturing environment effectively.

Tips: Foster collaborations between technology developers and traditional manufacturers to ensure a seamless transition to advanced practices. Training workers in new technologies is also vital to maximize the potential of these innovations, ensuring they contribute positively to productivity and quality.

The advent of 3D printing technology has revolutionized customization and production speed across various industries. Unlike traditional manufacturing methods, which often involve lengthy processes and standardization, 3D printing allows for rapid prototyping and the creation of highly personalized products. In sectors like healthcare, customized implants and prosthetics can be designed based on an individual’s specific anatomy, enhancing patient outcomes. This capability not only shortens the lead time for new medical devices but also reduces wastage associated with mass production.

Moreover, industries such as automotive and aerospace benefit significantly from 3D printing's flexibility. Designers can produce lightweight, complex components that were previously deemed impossible or too costly to manufacture using conventional techniques. This opens the door for innovative designs that enhance fuel efficiency and performance, while simultaneously accelerating the production lifecycle. As businesses increasingly adopt these advanced fabrication services, 3D printing's impact on customization and speed is likely to set a new standard for efficiency and personalization across all sectors.

Sustainable fabrication practices are increasingly becoming the cornerstone of eco-friendly industries, demonstrating a commitment to both innovation and environmental responsibility. By employing advanced materials such as biodegradable plastics and recycled metals, businesses are not only reducing their carbon footprints but also promoting a circular economy. This shift not only conserves resources but also meets the growing consumer demand for greener products, proving that sustainability can go hand-in-hand with profitability.

Innovative manufacturing processes, like additive manufacturing and digital fabrication, have revolutionized how products are created while minimizing waste. These technologies allow for precise material usage, significantly reducing excess and leftover material. Furthermore, many companies are integrating renewable energy sources into their operations, which not only decreases reliance on fossil fuels but also enhances their overall sustainability profile. As these practices gain traction, they are setting new standards across various sectors, proving that eco-friendly initiatives are not just trends, but vital components of future industrial success.

In recent years, robotic automation has significantly transformed the landscape of fabrication services, leading to unprecedented efficiency and precision in manufacturing processes. According to a report by the International Federation of Robotics, the use of industrial robots has surged by 12% annually, with projections indicating that the market will exceed 1.7 million units by 2023. This growth highlights a critical shift towards automation in various industries, allowing companies to streamline operations and reduce production time while maintaining high-quality standards.

The integration of robotic systems in fabrication not only enhances speed but also improves accuracy. A study from McKinsey & Company indicates that automation can reduce error rates by as much as 30%, addressing common issues in manual assembly processes. As manufacturers increasingly adopt robotic technologies, they are also able to leverage data analytics for real-time monitoring and optimization of workflows. This data-driven approach not only fosters better decision-making but also drives innovation in product design and development, propelling industries towards greater competitiveness in an ever-evolving market.

Emerging technologies in fabrication are revolutionizing the way industries operate, paving the way for more efficient and sustainable production processes. Advanced methods such as 3D printing, laser cutting, and robotics are not only enhancing manufacturing speed but are also allowing for greater customization and innovation. As companies adopt these technologies, they are finding that the ability to prototype and produce components rapidly gives them a competitive edge in the marketplace.

Tips for leveraging innovative fabrication technologies include staying informed about the latest advancements. Engaging with industry suppliers and attending trade shows can provide insights into new tools and techniques that could benefit production. Additionally, investing in training for employees ensures teams are skilled in utilizing these technologies effectively, maximizing the return on investment.

Another essential tip is to remain adaptable. As new fabricating technologies emerge, being open to integrating them into existing processes can lead to significant improvements in production efficiency and product quality. Regularly assessing the technological landscape allows businesses to identify opportunities for innovation and maintain a leading position within their industry.

| Industry | Fabrication Technology | Impact | Emerging Trends |

|---|---|---|---|

| Automotive | 3D Printing | Reduced weight, enhanced design flexibility | Lightweight materials, rapid prototyping |

| Aerospace | Additive Manufacturing | Lower production costs, improved performance | Custom components, sustainability initiatives |

| Healthcare | Bioprinting | Patient-specific implants, regenerative medicine | Tailored treatments, research advancements |

| Construction | Robotic Fabrication | Increased efficiency, precision | Automation in building processes, smart materials |

| Consumer Electronics | Laser Cutting | High precision, unique designs | Customization options, eco-friendly processes |