The manufacturing industry has reached a pivotal moment in its journey towards sustainability, and the role of moulds in this transformation cannot be overstated. With increasing pressure from consumers and regulatory bodies, companies are seeking innovative approaches that reduce waste and enhance resource efficiency. According to a report by the World Economic Forum, the adoption of sustainable manufacturing practices can improve productivity by up to 20%, while significantly cutting down carbon emissions. Moulds, as essential components in production processes, are key to achieving these goals.

Recent advancements in mould design and material technology have opened new avenues for sustainable practices. By utilizing eco-friendly materials and energy-efficient processes, manufacturers can minimize their environmental footprint. As highlighted in a study by the International Journal of Advanced Manufacturing Technology, innovations in mould-making are projected to reduce waste by 30% and energy consumption by 15% within the next decade. This shift not only addresses sustainability concerns but also enhances a company’s competitiveness in a rapidly evolving market.

In summary, moulds are not merely tools of production; they are integral to shaping a sustainable manufacturing future. As industries pivot towards greener methodologies, the importance of innovative moulds becomes evident, driving both ecological responsibility and economic benefits. Embracing these advancements is crucial for manufacturers aiming to thrive in a world increasingly focused on sustainability.

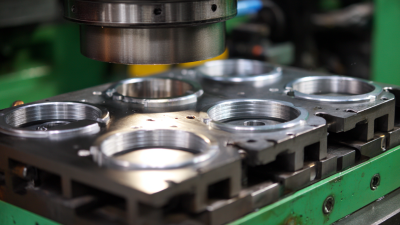

Innovative mould design techniques are revolutionizing sustainable manufacturing practices by significantly reducing waste and energy consumption. According to a report by the International Sustainable Manufacturing Consortium, innovative moulding processes can decrease material waste by up to 30%. This reduction is achieved through technologies such as 3D printing and computer-aided design, which allow for the creation of highly precise and optimised moulds. These advancements not only enhance the efficiency of the manufacturing process but also facilitate the use of sustainable materials, such as bioplastics, which are increasingly gaining traction in the industry.

Innovative mould design techniques are revolutionizing sustainable manufacturing practices by significantly reducing waste and energy consumption. According to a report by the International Sustainable Manufacturing Consortium, innovative moulding processes can decrease material waste by up to 30%. This reduction is achieved through technologies such as 3D printing and computer-aided design, which allow for the creation of highly precise and optimised moulds. These advancements not only enhance the efficiency of the manufacturing process but also facilitate the use of sustainable materials, such as bioplastics, which are increasingly gaining traction in the industry.

Furthermore, the application of simulation techniques in mould design can lead to improved energy efficiency during production. A study published by the Journal of Cleaner Production highlights that implementing advanced simulation during the mould-making process can decrease energy consumption by as much as 20%. These design techniques not only contribute to lower operational costs but also align with the broader goals of circular economy models, where resource efficiency and sustainability are paramount. As the manufacturing sector shifts towards more eco-friendly practices, innovative mould designs stand as a pivotal element in achieving sustainability-focused production.

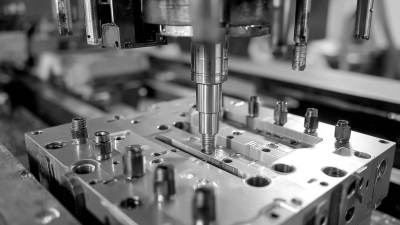

The integration of 3D printing technology in mould production is transforming the landscape of sustainable manufacturing practices. Traditional mould-making processes often produce significant material waste due to subtractive techniques, where excess material is cut away from larger blocks. In contrast, 3D printing allows for additive manufacturing, where material is built layer by layer. This not only minimizes waste but also enables the creation of complex geometries that were previously difficult, if not impossible, to achieve using conventional methods.

Furthermore, the use of biodegradable materials in 3D printing contributes to sustainability in mould production. As industries increasingly seek eco-friendly alternatives, the development of sustainable filaments supports the creation of moulds that are less harmful to the environment. This shift towards greener practices not only helps reduce the carbon footprint associated with manufacturing but also encourages a circular economy where materials can be reused and recycled more efficiently. Overall, the role of 3D printing in mould production signifies a significant stride towards more responsible and innovative manufacturing practices.

This chart illustrates the reduction in material waste percentage from traditional mould production methods compared to those utilizing 3D printing technology.

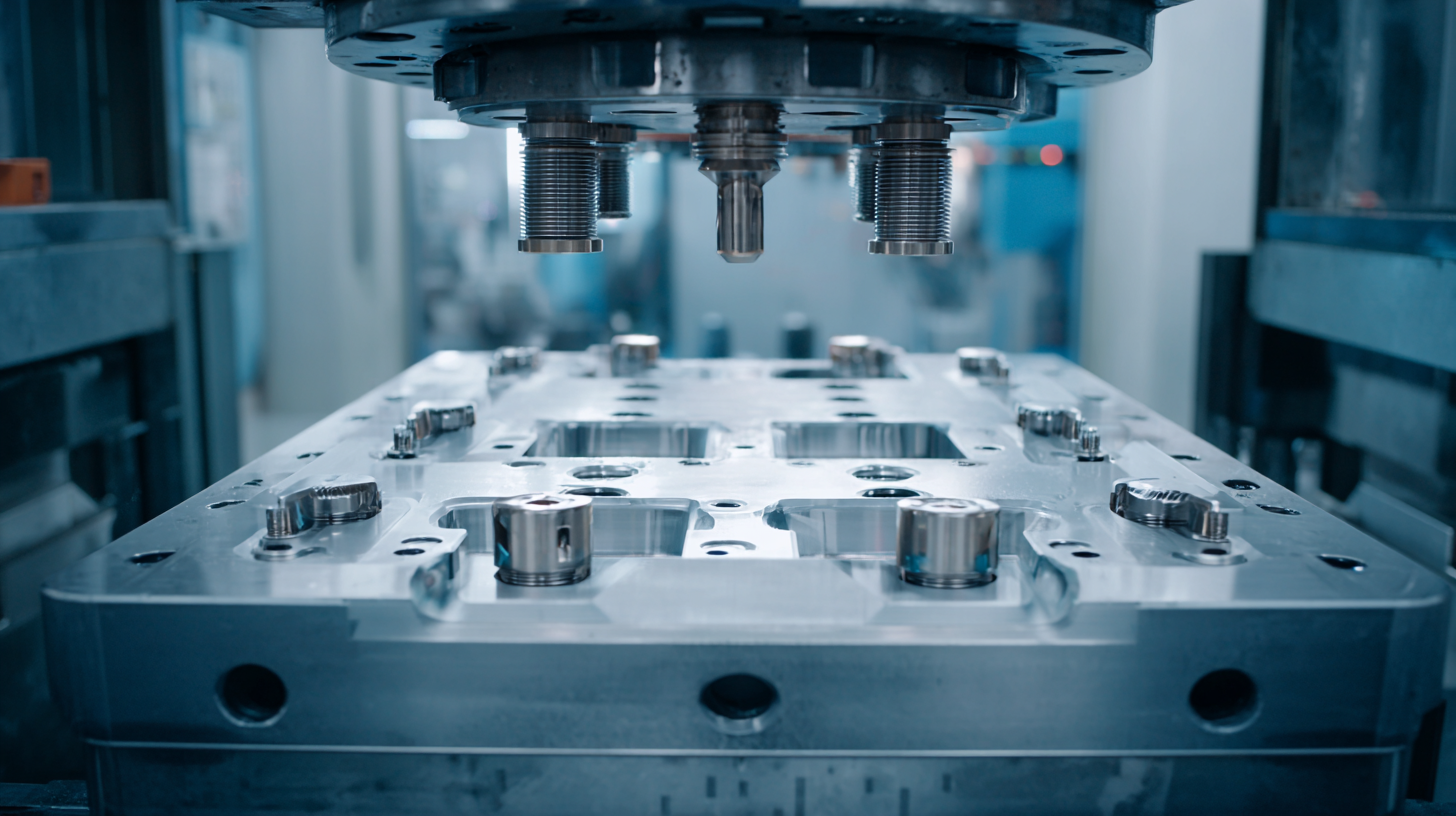

The transition towards sustainable manufacturing practices is gaining momentum, particularly in the realm of mould design and production. Case studies showcasing the successful application of eco-friendly moulds illustrate the potential for significant reductions in environmental impact. For instance, a report by McKinsey & Company highlights that the adoption of bio-based materials in mould manufacturing could lead to a carbon footprint reduction of up to 70%. Companies such as BASF have embraced this shift, utilizing biodegradable plastics that enhance product end-of-life sustainability while maintaining high performance standards.

Moreover, the integration of advanced technologies in mould production has enabled manufacturers to optimize resources and minimize waste. A notable example is the use of additive manufacturing, which can reduce material waste by as much as 90% compared to traditional moulding techniques. A case study from Siemens demonstrates how their implementation of 3D-printed moulds not only lowered production costs by 30% but also improved lead times significantly. Initiatives like these not only drive operational efficiency but also contribute to the overarching goal of reducing industrial waste, thereby setting a precedent for others in the industry to follow.

The evolution of sustainable manufacturing practices is intricately linked to the advancement of innovative mould technologies. In recent years, data-driven approaches have emerged as crucial tools for optimizing mould lifecycles and enhancing resource efficiency. For instance, a report by the International Energy Agency indicates that implementing advanced data analytics can reduce manufacturing energy consumption by up to 25%, showcasing the significant impact of precise mould management. By leveraging real-time data, manufacturers can predict wear and performance issues, allowing them to schedule maintenance proactively and extend the lifespan of their moulds.

Tips: Integrate smart sensors in your moulding equipment to continuously monitor performance metrics. These insights can lead to timely interventions, reducing downtime and maintenance costs, while promoting a more sustainable production process.

Moreover, using simulation software to model mould performance under various conditions can further enhance resource utilization. A study published in the Journal of Cleaner Production found that companies that adopted simulation techniques reduced material waste by approximately 15% during the mould design phase. Embracing these data-driven methodologies not only fosters sustainability but also yields significant economic benefits for manufacturers striving to remain competitive in the industry.

The future of sustainable manufacturing is increasingly shaped by innovative moulding solutions that prioritize biodegradability and smart technologies. According to industry experts, the 3D printing sector is predicted to surpass $40 billion by 2030, driven by advancements in material science and manufacturing processes. As businesses adopt these technologies, the emphasis on biodegradable materials will likely revolutionize the landscape, enabling manufacturers to reduce waste and environmental impact significantly.

To stay ahead in this rapidly evolving environment, manufacturers should consider several key strategies. First, adopting smart moulding solutions that utilize AI and IoT can optimize production processes, improving efficiency and reducing costs. Second, investing in biodegradable materials not only supports sustainability goals but can also attract eco-conscious consumers increasingly prioritizing environmentally friendly products.

Tips: It's essential to conduct thorough market research before adopting new technologies to understand their long-term viability and ROI. Additionally, collaborating with startups focused on sustainable innovations can provide greater insights into emerging trends and solutions within the industry. Embracing these practices today can position businesses favorably for the sustainable landscape of tomorrow.

| Material Type | Properties | Applications | Sustainability Impact | Smart Moulding Technology |

|---|---|---|---|---|

| PLA (Polylactic Acid) | Biodegradable, High tensile strength | Food packaging, Disposable cutlery | Reduces plastic waste, Compostable | Digital temperature control |

| PHBV (Polyhydroxybutyrate-co-valerate) | Flexible, Biodegradable | Biomedical applications, Packaging | Eco-friendly, Biodegrades in soil | AI-driven process optimization |

| Bio-resins | Renewable resources, Customizable properties | Automotive parts, Electronics | Lower carbon footprint, Non-toxic | Smart sensors for defect detection |

| Sugarcane-based Polymers | Renewable, Strong, Lightweight | Consumer goods, Packaging | Sustainable sourcing, Reduces reliance on fossil fuels | Automated moulding adjustments |