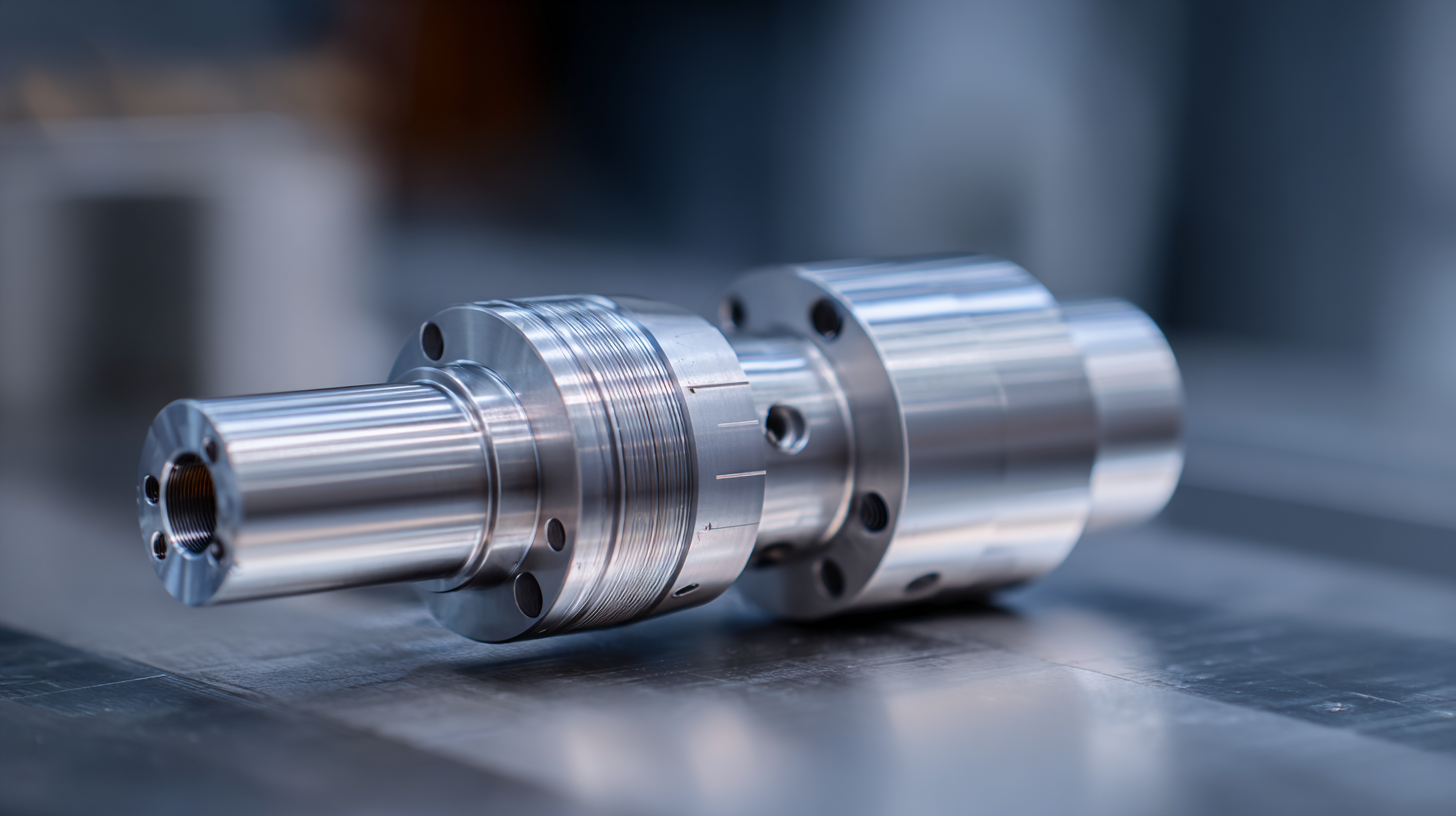

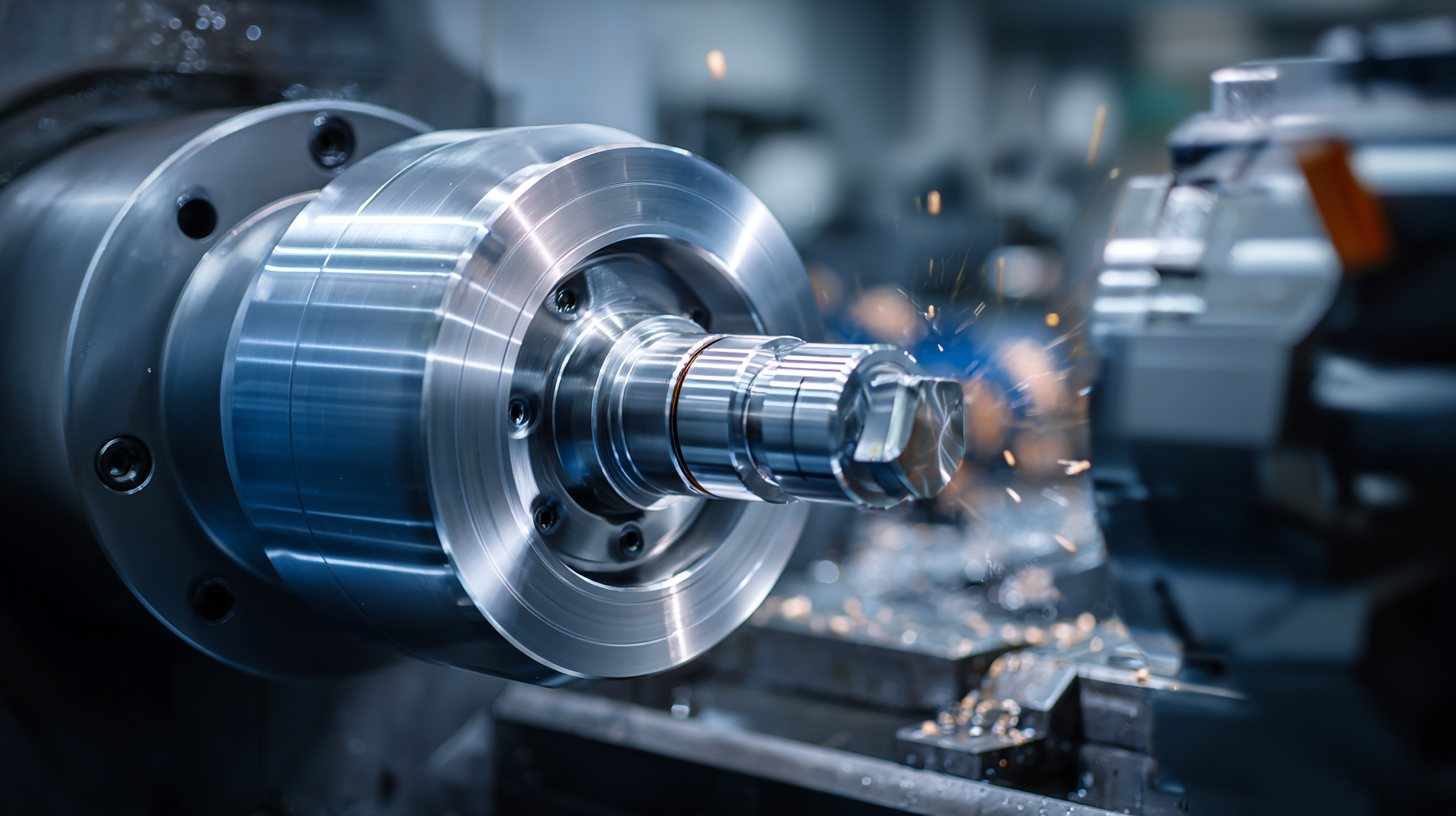

In today’s highly competitive manufacturing landscape, the significance of obtaining the right import and export certifications cannot be overstated, especially for businesses involved in the production of CNC machining parts. According to a recent report by Research and Markets, the global CNC machining market is projected to reach $117 billion by 2027, driven by the growing demand for precision parts in industries such as automotive, aerospace, and electronics. However, navigating the complex maze of certifications can be a daunting task for companies aiming to ensure compliance and maintain quality standards. Understanding the nuances of certification processes not only safeguards against legal risks but also enhances marketability and client trust. This guide will elucidate the essential steps and considerations for securing the necessary certifications for CNC machining parts, positioning your business for success in both local and international markets.

Import and export certifications play a crucial role in the CNC machining industry, impacting everything from compliance to market access. These certifications ensure that manufacturers adhere to international quality standards, environmental regulations, and safety requirements. For businesses looking to expand their reach globally, obtaining the necessary certifications can be a significant differentiator, as they signal reliability and commitment to excellence. Without these certifications, companies may face delays, increased costs, or even legal issues when attempting to enter foreign markets.

Moreover, the importance of these certifications extends beyond regulatory compliance; they can enhance a company’s reputation. Customers increasingly prioritize working with suppliers who demonstrate adherence to best practices in quality assurance. By navigating the complex landscape of import and export certifications, CNC machining companies can position themselves more favorably in the competitive marketplace. Ultimately, investing time and resources into understanding and obtaining these certifications not only aids in compliance but also paves the way for sustainable growth and long-term success in international operations.

In the world of CNC machining, the significance of import and export certifications cannot be overstated. Certifications such as ISO 9001, ISO 13485, and RoHS play a crucial role in ensuring quality and compliance. According to a report from the International Organization for Standardization (ISO), over 1.5 million ISO 9001 certificates were issued globally by the end of 2021, reflecting a growing emphasis on quality management systems in manufacturing. This trend highlights how manufacturers who obtain these certifications can enhance their credibility and competitiveness in the international market.

CNC machining parts intended for export often require additional certifications such as CE marking for compliance within the European market or FDA approval for medical device components. The global CNC machine market is projected to reach $117 billion by 2027, as noted in a study by Grand View Research. With such growth, the necessity of adhering to these certifications becomes paramount for suppliers who wish to penetrate diverse markets. Understanding the implications of these certifications not only ensures legal compliance but also fosters consumer confidence, leading to increased sales and long-term business sustainability.

| Certification | Description | Implications for CNC Machining Parts | Region/Market |

|---|---|---|---|

| ISO 9001 | Quality Management Systems | Ensures consistent quality in manufacturing. | Global |

| CE Marking | European Conformity | Indicates compliance with EU safety and environmental standards. | European Union |

| RoHS | Restriction of Hazardous Substances | Limits hazardous materials in electronic products. | European Union |

| UL Certification | Underwriters Laboratories | Indicates product safety and reliability standards. | North America |

| FDA Approval | Food and Drug Administration | Necessary for medical devices and food contact materials. | United States |

When selecting a reliable CNC machining supplier, it's critical to prioritize those with the necessary certifications that ensure compliance with industry standards. Certifications such as ISO 9001 demonstrate a supplier's commitment to quality management systems, which is essential for maintaining consistency in manufacturing processes. In fact, data indicates that companies with these certifications can experience up to 20% improved operational performance. Furthermore, suppliers involved in the defense sector must adhere to specific regulations, such as ITAR (International Traffic in Arms Regulations), which adds another layer of compliance that should not be overlooked.

When selecting a reliable CNC machining supplier, it's critical to prioritize those with the necessary certifications that ensure compliance with industry standards. Certifications such as ISO 9001 demonstrate a supplier's commitment to quality management systems, which is essential for maintaining consistency in manufacturing processes. In fact, data indicates that companies with these certifications can experience up to 20% improved operational performance. Furthermore, suppliers involved in the defense sector must adhere to specific regulations, such as ITAR (International Traffic in Arms Regulations), which adds another layer of compliance that should not be overlooked.

Working with certified suppliers not only reduces the risks associated with product quality but also enhances your credibility in the marketplace. A recent report highlighted that manufacturers partnering with certified suppliers enjoyed a 15% boost in customer satisfaction ratings, as consistency and reliability became hallmarks of their product offerings. Moreover, in the global landscape, CE marking is crucial for compliance with EU safety and environmental standards, enabling manufacturers to access broader markets. Hence, businesses prioritizing partnerships with certified CNC machining suppliers are more likely to succeed in a competitive environment, making informed supplier selection a cornerstone of effective supply chain optimization.

When dealing with CNC machining parts, ensuring compliance with import and export regulations is not just a legal requirement but a crucial factor for business success. One of the best practices is to familiarize yourself with the relevant regulations in both your home country and the countries you do business with. This means understanding tariffs, trade agreements, and any specific certifications that might be necessary for your products. Engaging legal experts or compliance specialists can provide valuable insights that help navigate these complex requirements effectively.

Additionally, maintaining clear documentation throughout the import and export process is essential. This includes keeping accurate records of all transactions, shipments, and certifications. Utilizing a centralized digital management system can streamline this process, making it easier to track compliance and provide necessary documentation when requested by customs authorities.

Establishing strong relationships with suppliers and logistics providers can also facilitate smoother transactions, ensuring that all certification requirements are met and reducing the risk of delays or penalties. By adopting these best practices, businesses can safeguard their operations while enhancing their global reach.

Navigating the complexities of import and export certifications is essential for ensuring the success of CNC machining parts in the global market. Manufacturers often face numerous challenges, such as understanding regulatory requirements and navigating bureaucratic red tape. Each country has its own set of rules and standards that can complicate the certification process, leading to delays and increased costs. This makes it vital for businesses to stay informed about the latest regulations and compliance requirements to avoid penalties and ensure a seamless supply chain.

Moreover, communication is key when dealing with certification agencies and customs officials. Companies must establish strong relationships and maintain open lines of communication to effectively address any potential issues. A proactive approach, such as investing in training for employees who manage these processes, can significantly enhance a company's ability to navigate these challenges. By prioritizing awareness and communication, CNC manufacturers can streamline certification processes and gain a competitive edge in the global market, ultimately driving better business outcomes.

This chart illustrates the percentage of CNC machining parts requiring different types of certifications for successful import and export processes. Understanding these certifications helps streamline operations and ensure compliance in global markets.