In today's interconnected world, the demand for efficient and reliable CNC milling services has never been greater. According to a report by Mckinsey & Company, nearly 70% of manufacturers believe that optimizing their supply chain is essential for achieving competitiveness in the global market. CNC milling services play a crucial role in this optimization, allowing companies to produce high-precision components that meet the stringent standards of various industries, from aerospace to automotive.

The global CNC machining market is projected to reach approximately $100 billion by 2025, underscoring the importance of adopting advanced strategies to enhance service efficiency and responsiveness. As manufacturers navigate complex supply chains, understanding how to streamline CNC milling services will be vital for success in the evolving landscape.

In today's interconnected world, the importance of CNC milling in the global supply chain cannot be overstated. Understanding the fundamentals of CNC milling involves recognizing its essential role in maintaining precision and efficiency in manufacturing processes. The global CNC machine market is projected to grow from $101.22 billion in 2025 to an astonishing $195.59 billion by 2032, reflecting a CAGR of 9.9%. This growth is largely driven by the increasing demand for high-quality components across various industries, including automotive, aerospace, and electronics.

To stay competitive in this expanding market, manufacturers must focus on optimizing their CNC milling services. One effective strategy is to leverage advanced technologies such as automation and AI. By integrating these innovations, companies can enhance machining accuracy and reduce lead times, thus meeting tight deadlines and higher customer expectations.

Tips: Ensure your CNC milling machines are regularly maintained to prevent downtime. Additionally, consider offering customized solutions to cater to the specific needs of global clients. By being adaptable and forward-thinking, businesses can secure a strong position in the global CNC landscape.

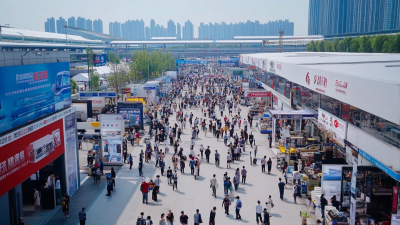

The global CNC milling market is poised for significant growth, projected to expand from a valuation of $25.01 billion in 2018 to $57.54 billion by 2032, reflecting a robust compound annual growth rate of 5.6%. This surge is largely attributed to the increasing demand for precision manufacturing, particularly in emerging markets across Asia, where innovative advancements in smart manufacturing are creating abundant market opportunities. By leveraging advanced technologies driven by artificial intelligence, CNC milling services are experiencing enhancements in efficiency, leading to faster production cycles and improved quality of output.

Key factors influencing CNC milling efficiency include automation and the integration of intelligent systems. The implementation of collaborative robots offers a solution to the pressing challenges of reduced labor costs and increased production speeds. Furthermore, the rise of Industry 4.0 emphasizes the interconnectedness of machinery, which allows for real-time monitoring and data analysis, ensuring consistent quality and efficiency. These technological evolutions are transforming CNC milling services, making them indispensable for businesses aiming to thrive in the competitive landscape of the global supply chain.

Integrating CNC milling into a supply chain requires a strategic approach that maximizes efficiency and reduces costs. According to a report from the Global CNC Machine Tool Market, the demand for CNC machining services has increased by over 5% annually, reflecting the growing importance of precision manufacturing across diverse industries. To effectively incorporate CNC milling into your supply chain, it’s essential to establish solid partnerships with reliable CNC service providers who can ensure timely delivery and maintain consistent quality standards.

Moreover, leveraging advanced technologies such as IoT and AI can significantly enhance CNC milling processes, leading to improved operational efficiencies. A study by Deloitte indicates that companies that embrace digital technologies within their supply chain can achieve up to a 20% reduction in costs and a 10% increase in operational speed. By utilizing data analytics, manufacturers can optimize their production schedules and minimize waste, thus creating a more agile supply chain that is better equipped to respond to market fluctuations and demands.

In today’s competitive landscape, optimizing CNC milling services through advanced technology is crucial for enhancing capabilities and ensuring supply chain success. According to a report by Markets and Markets, the CNC machine tools market is expected to reach $100 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.4%. This growth emphasizes the necessity for manufacturers to invest in cutting-edge technologies such as automation, AI, and IoT to streamline operations and improve efficiency.

Leveraging technology can significantly enhance precision and reduce downtime in CNC milling operations. By integrating IoT devices, manufacturers can monitor machinery in real-time, leading to predictive maintenance strategies that minimize disruptions. A study from Deloitte reveals that companies utilizing IoT technology experience a 10% increase in productivity and a notable reduction in operational costs. Furthermore, incorporating advanced software for design and simulation can optimize machining processes, ultimately leading to better resource management and faster turnaround times, creating a more agile global supply chain capable of responding swiftly to market demands.

This chart illustrates key performance metrics for optimizing CNC milling services within the global supply chain. Metrics include operational efficiency, lead time, cost reduction, and production volume.

Collaboration between suppliers is crucial in optimizing CNC milling services, especially in a global supply chain environment. According to a report by Deloitte, companies that actively engage in supplier collaboration can reduce their procurement costs by up to 20%. This highlights the importance of building strong relationships with suppliers to streamline operations and enhance efficiency. By fostering mutual trust and open communication, companies can leverage each other's strengths, leading to innovations in CNC milling processes that can significantly improve product quality and reduce lead times.

Integrating advanced technology solutions further enhances supplier collaboration in CNC milling services. A study from McKinsey & Company indicates that manufacturers adopting digital collaboration tools see a 25% increase in productivity. Implementing platforms that allow real-time data sharing and project tracking can help unify teams across geographical boundaries, ensuring that everyone stays aligned on goals and project timelines. Additionally, utilizing analytics to assess supplier performance can lead to informed decision-making, ensuring that only the best suppliers contribute to the supply chain. This not only boosts the overall quality of the milling services but also contributes to sustained business growth in an increasingly competitive global market.