In the competitive landscape of manufacturing, optimizing punch die performance has become a critical focus for companies aiming to enhance efficiency and reduce operational costs. According to a report by Grand View Research, the global metal stamping market is projected to reach $256.4 billion by 2025, highlighting the increasing reliance on advanced manufacturing techniques that incorporate punch die mechanisms. Issues such as die wear, inconsistent part quality, and maintenance costs can greatly hinder production timelines and profitability. Industry experts emphasize that leveraging innovative strategies in punch die design and application not only addresses these challenges but also drives substantial improvements in overall process efficiency.

As manufacturers seek to meet rising demand while maintaining quality, understanding and implementing the top strategies for optimizing punch die performance will be essential for sustaining competitive advantage in this evolving market.

In the realm of manufacturing, the performance of punch dies is critical to ensuring product quality and operational efficiency. According to a report by the International Journal of Advanced Manufacturing Technology, nearly 30% of production defects are attributed to suboptimal die performance. This highlights the necessity for manufacturers to prioritize the optimization of punch die parameters, as even minor improvements can lead to significant enhancements in output quality.

Additionally, a study from the Society of Manufacturing Engineers reveals that optimizing punch die performance can reduce production costs by up to 25%. This is primarily achieved through lower scrap rates and reduced machine downtime. Effective punch die maintenance strategies, such as regular inspections and timely replacements, can further enhance lifespan and reliability, contributing to a smoother production process. Therefore, acknowledging the importance of punch die performance not only safeguards product integrity but also ensures a more economically sustainable manufacturing operation.

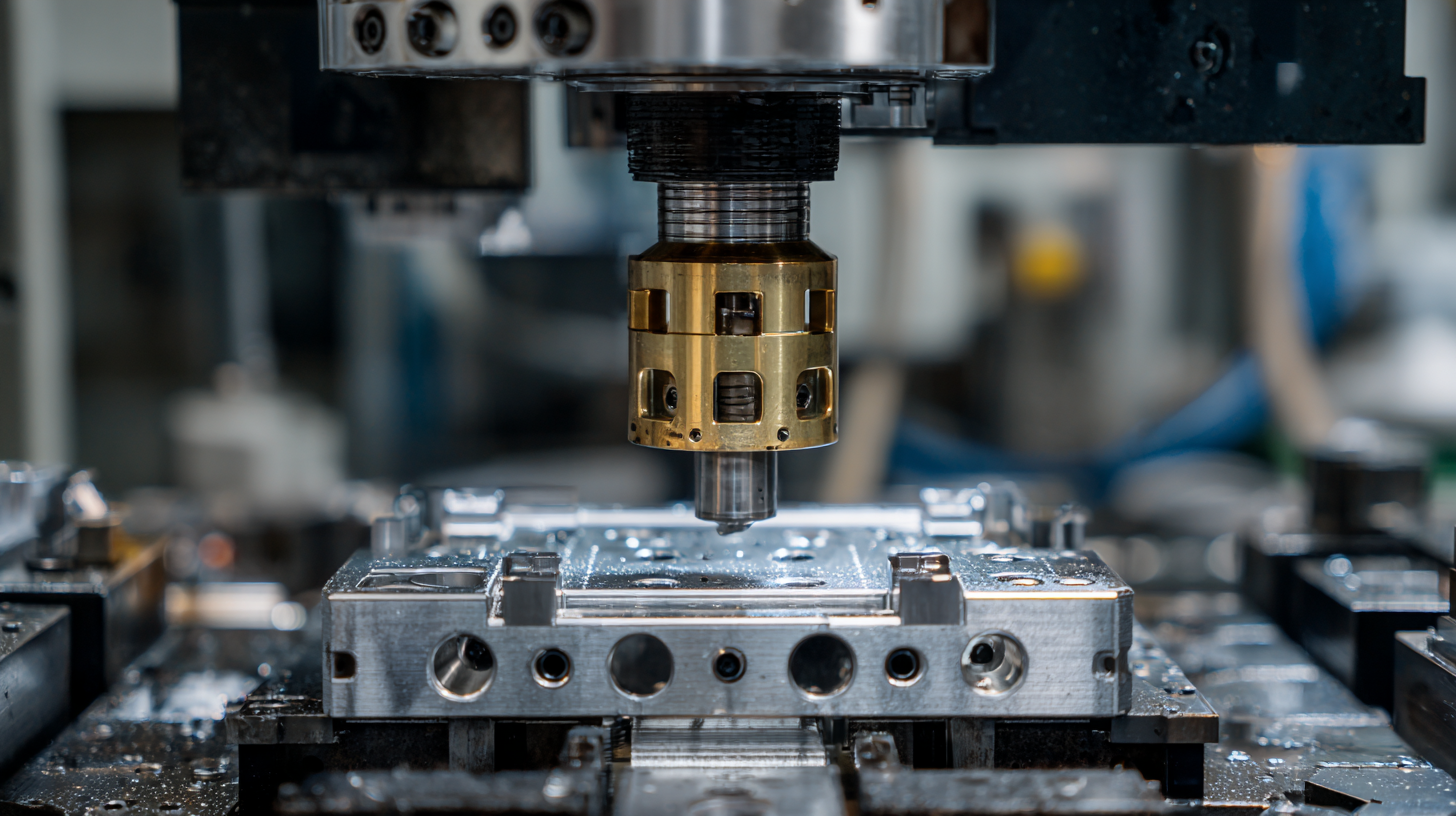

Punch dies play a crucial role in manufacturing processes, particularly in metalworking and stamping applications. Among the key factors influencing punch die efficiency, material selection stands out prominently. According to a 2022 report by the Manufacturing Institute, about 40% of die failures are attributed to suboptimal material choices. High-speed steel (HSS) and carbide are among the preferred options, providing durability and wear resistance that can increase the lifespan of the die by 30%, ultimately leading to reduced downtime and enhanced productivity.

Furthermore, the design and maintenance of punch dies significantly impact their performance. The same report highlights that nearly 25% of productivity loss in manufacturing can be traced back to inadequate die design. Implementing advanced simulation software during the design phase can help identify potential flaws and optimize the die geometry for specific production needs. Moreover, regular maintenance is essential; a comprehensive study from the Society of Manufacturing Engineers indicates that systematic maintenance can boost efficiency by up to 20% and prolong die service life, thereby enhancing overall production efficiency.

In the manufacturing sector, enhancing the durability and longevity of punch dies is crucial for maintaining efficiency and reducing production costs. Recent reports from the Technical Association of the Pulp and Paper Industry indicate that the use of advanced materials can significantly extend the service life of punch dies by up to 50%. High-speed steel (HSS) and carbides are commonly utilized for their excellent wear resistance and ability to withstand high-temperature environments, making them ideal for demanding manufacturing processes.

Moreover, innovative coatings such as TiN (Titanium Nitride) and CrN (Chromium Nitride) are transforming punch die performance. According to a study published by the Association for Iron and Steel Technology, tools coated with these materials demonstrate a reduction in friction and improved hardness, which can lead to a remarkable increase in operational efficiency. Furthermore, implementing these advanced materials not only optimizes punch die performance but also reduces the frequency of replacements, which is essential for minimizing downtime in production lines.

Embracing such technological advancements is vital for manufacturers seeking to remain competitive in a fast-evolving market.

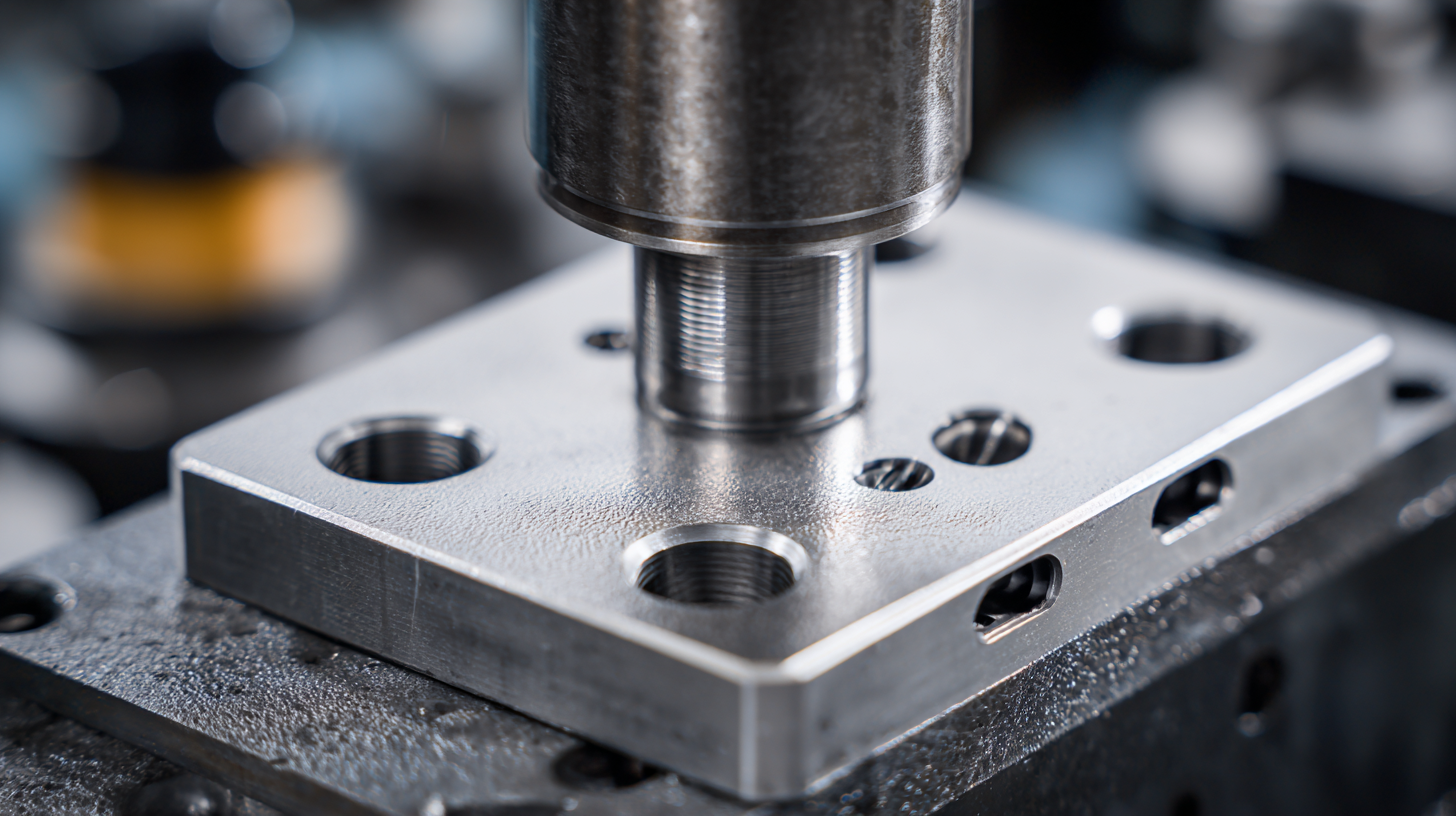

To ensure optimal punch die functionality in manufacturing processes, regular maintenance practices are crucial. According to a report by the International Society of Automation, approximately 30% of tooling failures are due to inadequate maintenance. Implementing a structured maintenance schedule can dramatically reduce downtime and improve tool performance. For instance, routine inspections and cleaning can prevent harmful build-up of debris that may lead to premature wear and tear.

Moreover, lubricating punch dies properly plays a significant role in extending their lifespan. The Society of Manufacturing Engineers found that proper lubrication can improve die performance by as much as 25%. Utilizing high-quality lubricants tailored for specific materials not only enhances tool efficiency but also minimizes friction, which can otherwise cause excessive heat and accelerate wear. Additionally, training personnel on best practices can create a culture of proactive maintenance, further ensuring that the punch dies operate at peak efficiency throughout their lifecycle.

In today's fast-paced manufacturing landscape, implementing technology for real-time monitoring of punch die performance is crucial for maximizing efficiency and minimizing downtime. Using advanced sensors and IoT devices, manufacturers can now collect live data on punch die usage, detecting any performance drops or abnormalities before they escalate into costly failures. This proactive approach not only enhances production quality but also prolongs the life of the tooling.

Tip 1: Integrate predictive analytics with your monitoring systems to forecast wear patterns and maintenance needs. By analyzing data trends, manufacturers can schedule maintenance activities during planned downtimes, reducing the risk of unexpected breakdowns.

Tip 2: Utilize a centralized dashboard that presents real-time insights into multiple punch dies across your facility. This allows for immediate adjustments to be made in the production process, ensuring optimal performance and reducing the risk of quality defects.

With these advancements, manufacturers are better equipped to maintain punch die efficiency, leading to improved overall productivity and lower operational costs.

| Strategy | Technology Implemented | Key Performance Indicator (KPI) | Impact | Frequency of Monitoring |

|---|---|---|---|---|

| Regular Maintenance Scheduling | Predictive Maintenance Software | Die Failure Rate | Reduction of 20% in failures | Weekly |

| Real-Time Die Performance Tracking | IoT Sensors | Punch Velocity | Improved efficiency by 15% | Real-Time |

| Data-Driven Decision Making | Analytics Software | Material Utilization Rate | Increased by 10% | Monthly |

| Enhanced Training for Operators | Virtual Reality (VR) Simulation | Operator Efficiency | Reduced error rates by 25% | Quarterly |

| Customized Die Design Improvements | CAD Software | Die Life Cycle | Extended lifespan by 30% | Bi-Annually |