In the rapidly evolving landscape of manufacturing, precision is paramount, particularly in CNC (Computer Numerical Control) machining, where the quality of parts for CNC significantly impacts overall performance and efficiency. According to a recent report by MarketsandMarkets, the global CNC machining market is expected to reach USD 100 billion by 2025, growing at a CAGR of 6.3% from 2020. This growth underscores the increasing reliance on advanced machining technologies, where the selection of high-quality parts for CNC machines becomes critical.

As the industry embraces innovation, manufacturers are tasked with sourcing components that not only meet exacting standards but also enhance productivity. "精工细造,中国制造,服务世界" encapsulates this commitment to excellence, emphasizing the need for precision-engineered parts that serve not just local but global demands, ultimately leading to improved operational efficiencies and competitive advantages in the market.

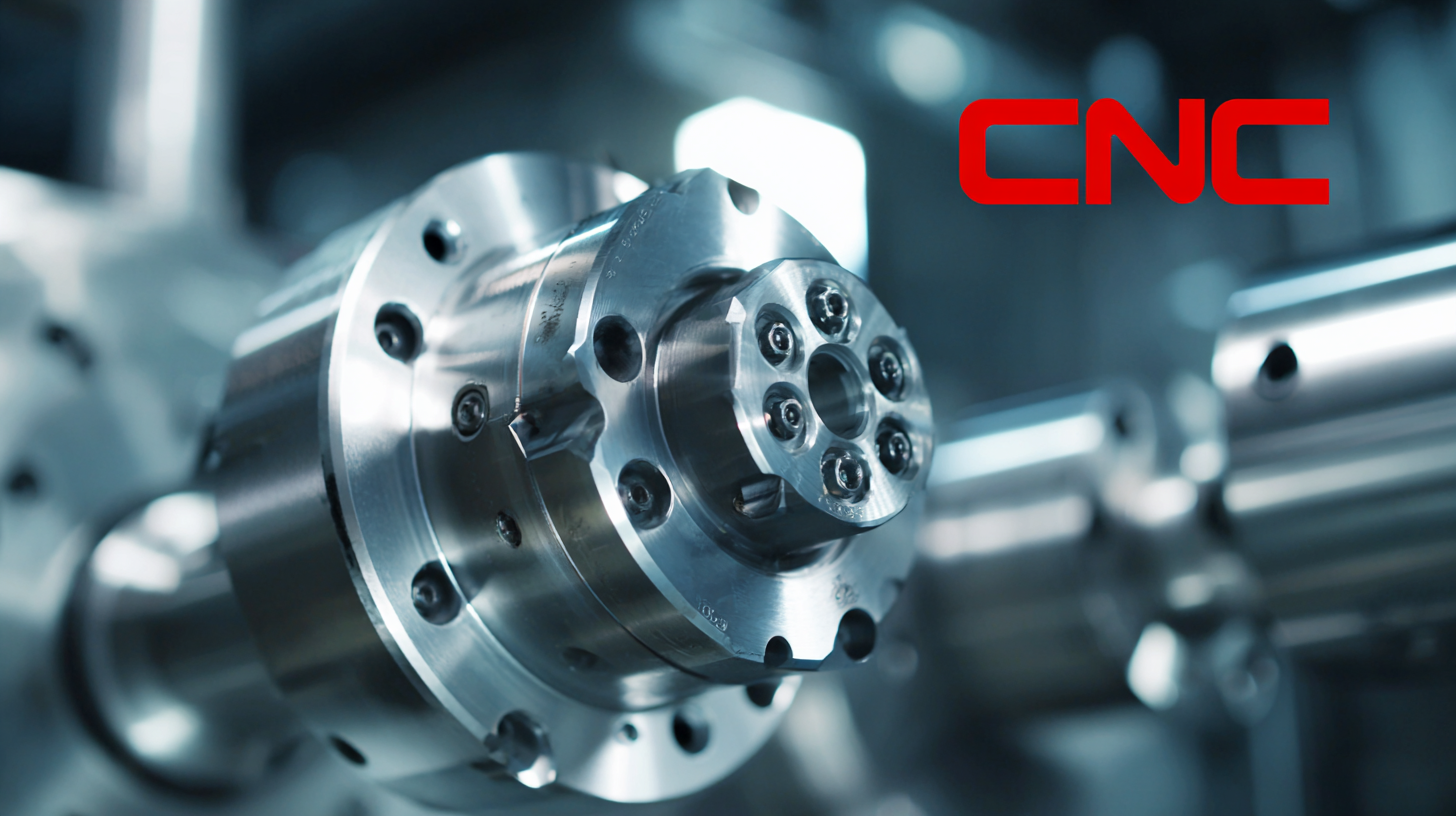

In the realm of CNC machining, precision parts play an indispensable role in enhancing overall performance and efficiency. The integration of advanced technologies, such as artificial intelligence, is revolutionizing the manufacturing landscape. AI-driven machinery can optimize cutting processes and tool paths, resulting in higher accuracy and reduced waste. This synergy between precision components and intelligent technology ensures that manufacturers can meet the rising demands for quality and efficiency, ultimately shaping the future of production.

Moreover, the evolution of high-performance grinding functions and the burgeoning precision tool market highlights the increasing value placed on precision parts in CNC applications. Cutting-edge solutions are being deployed to improve tool effectiveness, leading to superior output quality. Leveraging techniques such as digital twins enables manufacturers to simulate and analyze workflows, minimizing errors and enhancing productivity. As we advance, the focus on precision not only caters to market growth but also underscores its critical role in the transformation of modern manufacturing.

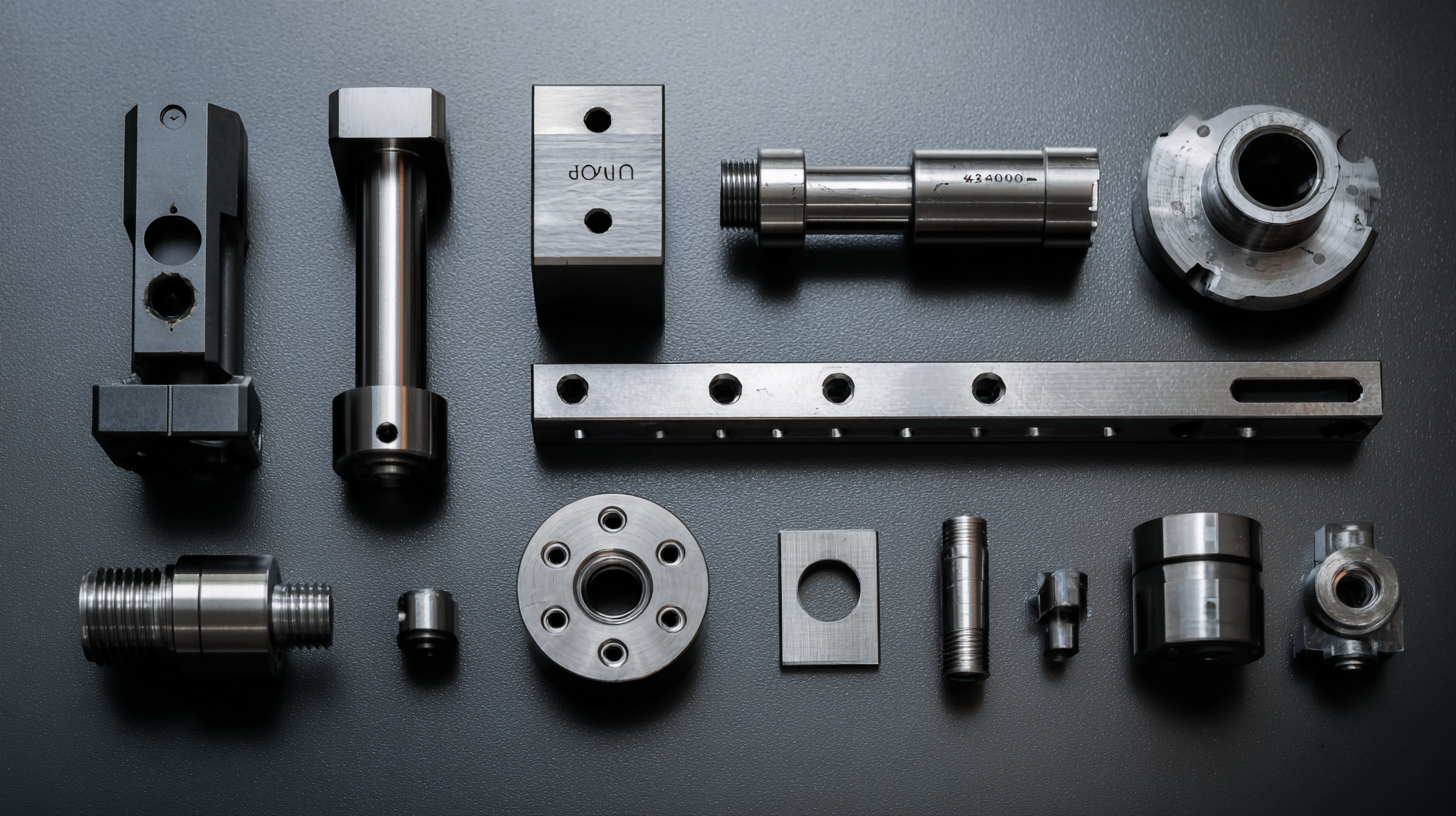

| Part Type | Material | Precision Level (µm) | Typical Applications | Maintenance Frequency (Months) |

|---|---|---|---|---|

| Spindle | Steel | 5 | High-speed machining | 3 |

| Tool Holder | Aluminum | 10 | Milling operations | 6 |

| Cutting Tool | Carbide | 2 | Precision cutting | 1 |

| Clamp | Plastic | 20 | Workpiece holding | 12 |

| Guide Rail | Cast Iron | 15 | Linear motion | 24 |

CNC machining efficiency is influenced by several key factors that determine the overall performance and output of the manufacturing process. One crucial element is the

quality of the components used in CNC machines. High-quality parts not only enhance precision but also lead to improved

durability and reduced maintenance costs. The right choice of tools, such as cutting blades and fixtures, can significantly

optimize machining operations, allowing for faster cycle times and better surface finishes

on the final products.

Another important aspect is the technological advancements in the CNC industry. Innovations in tooling materials and machining techniques

contribute to enhanced capabilities and versatility, enabling manufacturers to tackle complex designs and improve throughput. Moreover,

understanding market trends, including growth projections in sectors like automotive, precision machinery, and general mechanical

applications, helps businesses align their strategies to meet the evolving demands. Regional dynamics also play a role, as varying economic environments can affect supply chains, labor costs,

and overall investment in machining technologies. Addressing these factors holistically can lead to significant improvements in efficiency and productivity in CNC machining processes.

In the realm of CNC machining, material selection plays a critical role in determining the efficiency and performance of the final product. Recent advancements in additive manufacturing (AM) technologies have showcased significant material efficiency potential when contrasted with traditional subtractive approaches. These innovations allow for the production of complex geometries while minimizing waste, thus positioning AM as a pivotal alternative in the modern manufacturing landscape.

A notable area of investigation is the impact of residual stress on the quality and accuracy of machined components. Understanding the distortion caused by initial residual stresses present in raw materials, as well as those introduced during the machining process, is crucial. For instance, implementing finite element analysis can help optimize the structure of high-precision machine tools, enhancing their dynamic and static performance, ultimately leading to improved machining efficiency and product quality. With these insights, manufacturers can refine their material choices and machining strategies to achieve greater precision and operational reliability.

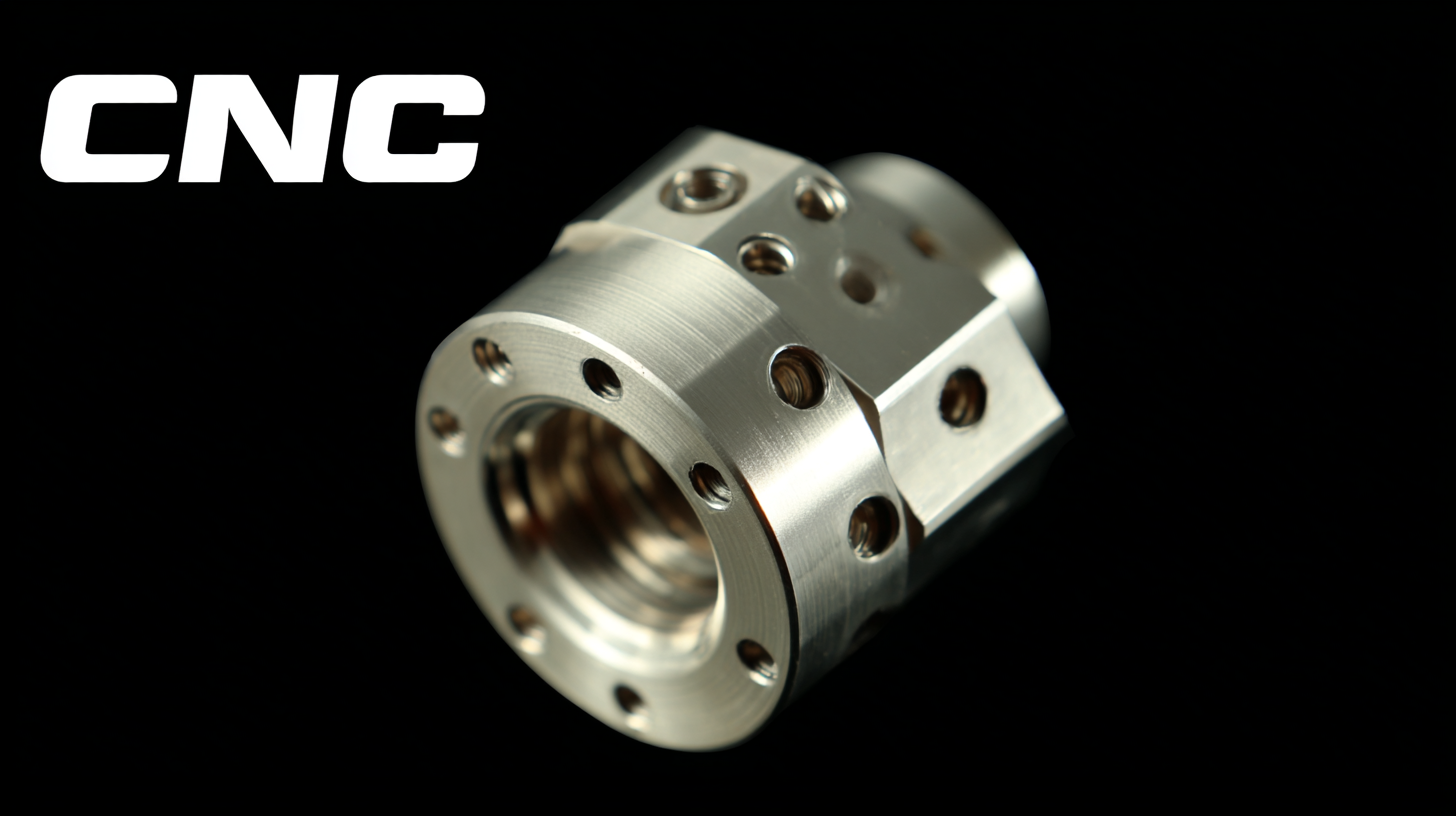

When it comes to CNC machining, the quality of components directly influences the precision and efficiency of the final product. Evaluating component quality requires understanding various factors, including material selection, manufacturing tolerances, and surface finishes.

High-quality materials—such as aerospace-grade aluminum or tool steel—offer enhanced strength and durability, enabling parts to withstand rigorous machining processes without deforming or degrading over time.

Additionally, tight tolerances are crucial to achieving the desired performance in CNC applications. Components manufactured with precision engineering ensure that each piece fits seamlessly within complex assemblies, minimizing the risk of errors or malfunctions.

Surface finish is another critical aspect; a well-finished surface reduces friction and wear, contributing to the longevity of both the part itself and the machinery overall. By prioritizing these quality indicators, manufacturers can unlock the full potential of CNC machining, leading to improved operational efficiency and outstanding results.

In the competitive landscape of CNC machining, the challenge of balancing cost and performance has never been more critical. According to a recent report by Deloitte, optimizing CNC machining efficiency can lead to a productivity increase of up to 30%. However, achieving this optimization often hinges on the components chosen for each machine. High-performance parts may come with a steeper price tag, but they can significantly reduce downtime and increase the longevity of the machinery, ultimately leading to cost savings in the long term.

Finding the right balance in selecting CNC machining parts requires a thorough understanding of project requirements and operational budgets. A study by the SME (Society of Manufacturing Engineers) indicated that 60% of manufacturers prioritize quality over cost, realizing that investing in superior components can lead to enhanced precision and decreased scrap rates. For instance, using advanced tooling materials like carbide versus standard steel can yield a 50% increase in tool life. Thus, companies must carefully evaluate their options, considering both initial expenses and the potential for performance gains when choosing CNC machining parts.