The process of punching mould manufacture plays a vital role in various industries, from automotive to electronics, as it involves the precision shaping and cutting of materials. According to a recent market research report by Mordor Intelligence, the global die and mould market is projected to reach USD 88.16 billion by 2026, growing at a CAGR of 5.9% during the forecast period. This growth highlights the increasing demand for efficient and reliable punching moulds that cater to diverse applications. With advancements in technology and techniques, manufacturers are continually improving the accuracy and efficiency of punching processes, leading to higher production rates and reduced waste. This blog will delve into the intricacies of punching mould manufacture, exploring best practices, common challenges, and practical tips for maximizing productivity and quality in production lines.

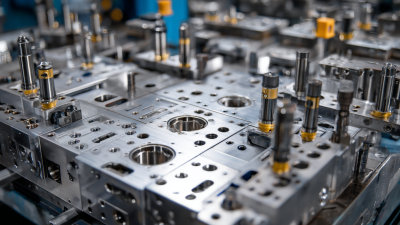

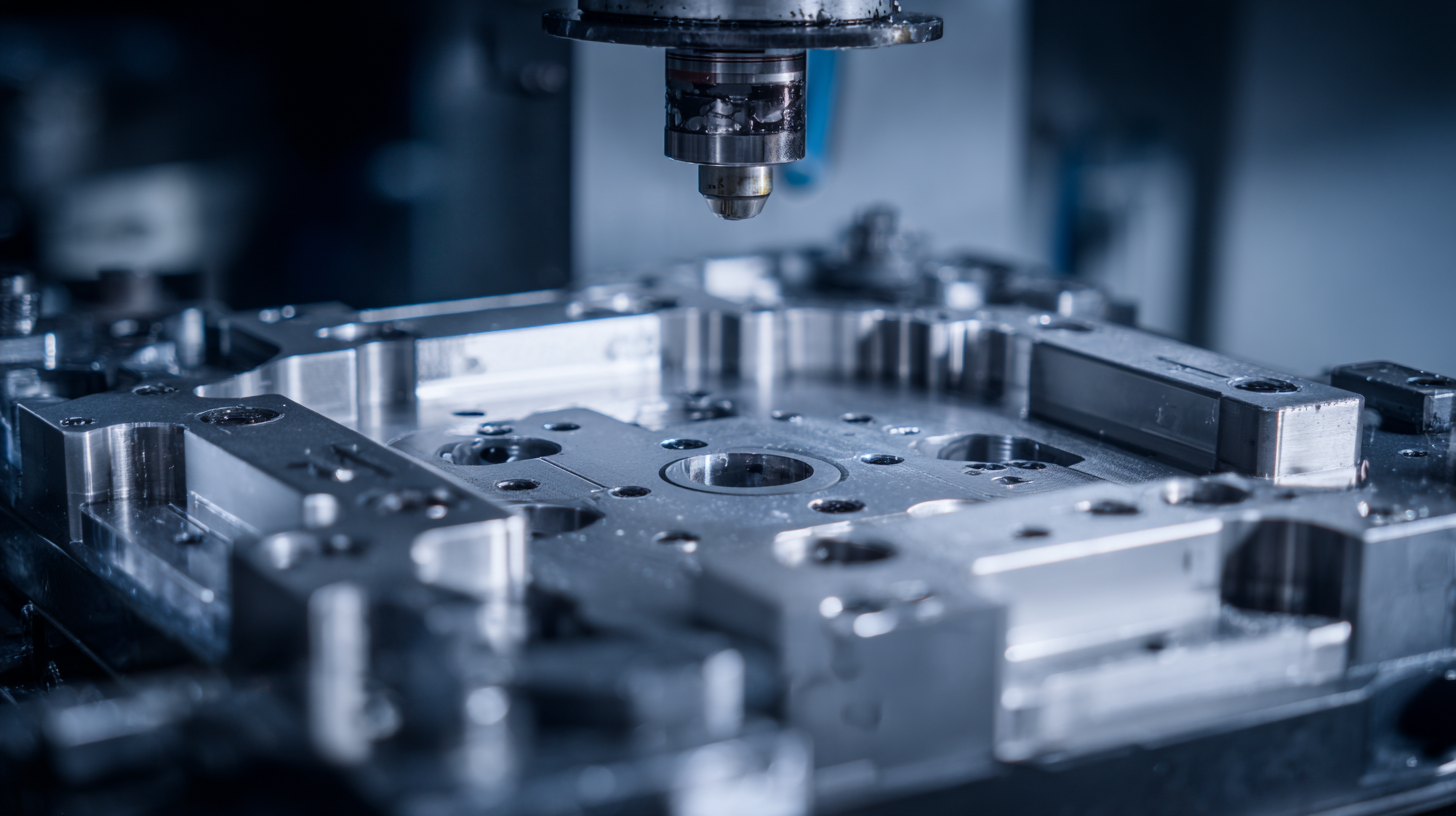

Punching mould design is a critical aspect of manufacturing that combines engineering principles with creativity to produce efficient and effective moulds. The process begins with understanding the specific requirements of the end product, including material type, thickness, and the desired shape. Designers must consider factors such as the type of punch and die, clearance between them, and the overall geometry of the mould. Advanced software tools are often utilized to create detailed simulations, which help in optimizing the design for maximum durability and precision.

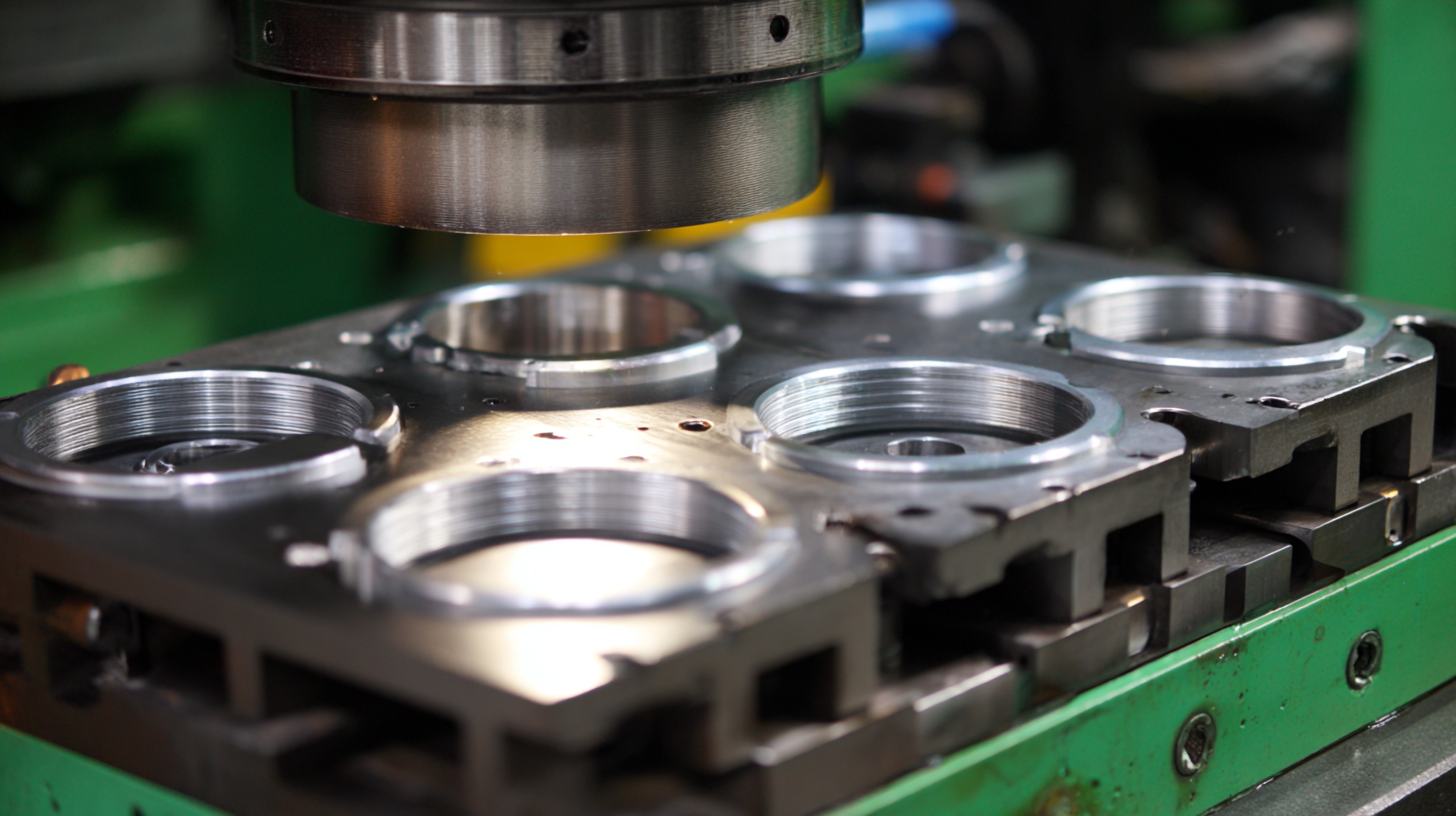

Construction techniques play a significant role in the efficacy of punching moulds. High-quality materials are chosen based on their wear resistance and strength to withstand repetitive impacts during the punching process. Additionally, precision machining methods, such as CNC milling and electrical discharge machining (EDM), are employed to ensure that each component meets strict tolerances. The integration of modern technology, such as laser cutting, further enhances the accuracy of the mould construction. These techniques collectively contribute to the overall performance of the punching mould, making it suitable for various applications across different industries, from automotive to electronics.

In the realm of punching mould manufacture, the choice of materials is crucial to achieving the desired functionality and durability of the moulds. Commonly used materials include high-strength steel, aluminum alloys, and increasingly, composite materials. These composites bring unique advantages to the manufacturing process, such as enhanced strength-to-weight ratios and improved resistance to corrosion. Their application in industrial processes signifies a shift from traditional metals, optimizing performance while minimizing weight, which is particularly relevant in industries like automotive manufacturing.

Moreover, innovations in processing techniques, including high-pressure spark plasma sintering (HPSPS), have opened new avenues for enhancing the properties of these materials. By applying specific pressures, manufacturers can achieve remarkable densification, resulting in moulds with superior mechanical and physical properties. The integration of advanced materials and innovative processing methods not only elevates the efficiency of mould production but also extends the lifespan and functionality of the resulting components across various applications. This interplay between material science and engineering practices is progressively shaping the future of punching mould manufacture.

Punching mould manufacturing is a meticulous process that transforms raw materials into precise components used in various industries. The journey begins with designing the mould, where engineers create blueprints that detail dimensions and specifications. This initial step is crucial, as it sets the foundations for the entire manufacturing process. Once the design is approved, the next stage involves selecting suitable materials, typically high-density steel, which provides the durability needed to withstand repeated use.

In the production phase, the central element is the machining process. Here, advanced techniques such as CNC machining and wire EDM come into play to shape the mould accurately. This stage requires careful attention to detail, as any discrepancies can affect the final product's quality. Tips for this phase include regular maintenance of machinery to ensure precision and conducting quality checks throughout the process to prevent errors.

Finally, the mould undergoes rigorous testing to confirm its performance before being delivered to clients. This includes not only functional tests but also assessments of wear and tear. A key tip here is to document all findings meticulously; this will help in fine-tuning future mould designs and improving manufacturing processes over time.

Punching moulds play a crucial role in various industries, offering precision and efficiency in manufacturing processes. One of the key applications of punching moulds is in the production of glass components, such as windows and mirrors. The glass moulding process requires meticulous attention to detail, as the quality and durability of the final products depend heavily on the precision of the moulds used. In sectors like the beverage and pharmaceutical industries, custom punching moulds enable manufacturers to create specialized packaging that meets strict regulatory standards while enhancing product safety and consumer convenience.

Beyond glass manufacturing, punching moulds are also pivotal in the automotive and tire industries. The demand for high-quality tire moulds has surged, driven by the need for improved performance and safety in vehicles. As technology evolves, manufacturers are embracing advanced techniques, such as the use of automated moulding processes, which significantly increase production efficiency and reduce costs. This shift not only caters to the growing market needs but also propels innovation within the industry, ensuring that punching moulds remain an integral component of modern manufacturing across various sectors.

When it comes to maintaining punching moulds, following best practices is essential to ensure their longevity and performance. Regular inspection is a crucial step; operators should routinely check for wear and tear, including any signs of rust, cracking, or deformation. This proactive approach allows for early detection of potential issues, reducing downtime and costly repairs. Additionally, keeping the moulds clean is vital since accumulated debris can interfere with the precision and functionality of the punching process. A thorough cleaning regimen using appropriate solvents can help in maintaining the integrity of the mould.

Quality control is another critical aspect of punching mould maintenance. Establishing a consistent quality assurance process helps to identify variances in mould performance, such as dimensional accuracy and surface finish. Implementing statistical process control (SPC) techniques can aid in monitoring the production parameters and ensuring that they remain within specified limits. Moreover, careful material selection and periodic testing of the moulds can enhance their durability and performance. By prioritizing these practices, manufacturers can significantly improve the output quality and efficiency of their punching operations.

This chart illustrates the impact of various dimensions of punching mould manufacture on overall mould performance. The data represents the relative performance percentage in key areas such as material quality, precision in machining, and maintenance frequency, highlighting best practices for maintenance and quality control.