In the rapidly evolving landscape of modern manufacturing, the role of a metal mold manufacturer has become increasingly significant in shaping production efficiency and product quality. As industries strive for innovation and competitiveness, the expertise of metal mold manufacturers is paramount in creating precision molds that drive the manufacturing processes of a wide range of products. From automotive components to consumer goods, the intricate designs and durable molds produced by these manufacturers are crucial for achieving high standards of accuracy and repeatability in production. By understanding the intricacies of how metal mold manufacturers operate, including their design capabilities, materials selection, and technological advancements, businesses can enhance their own manufacturing strategies, reduce costs, and improve their overall output. This article will explore the essential contributions of metal mold manufacturers in contemporary manufacturing environments, illustrating best practices and key considerations for companies looking to optimize their mold-making processes.

In the rapidly evolving landscape of modern manufacturing, the role of a metal mold manufacturer has become increasingly significant in shaping production efficiency and product quality. As industries strive for innovation and competitiveness, the expertise of metal mold manufacturers is paramount in creating precision molds that drive the manufacturing processes of a wide range of products. From automotive components to consumer goods, the intricate designs and durable molds produced by these manufacturers are crucial for achieving high standards of accuracy and repeatability in production. By understanding the intricacies of how metal mold manufacturers operate, including their design capabilities, materials selection, and technological advancements, businesses can enhance their own manufacturing strategies, reduce costs, and improve their overall output. This article will explore the essential contributions of metal mold manufacturers in contemporary manufacturing environments, illustrating best practices and key considerations for companies looking to optimize their mold-making processes.

In today's production landscape, metal mold manufacturing plays a crucial role in driving efficiency and innovation across various industries. As manufacturers strive for faster, cheaper, and more sustainable solutions, the incorporation of advanced technologies like 3D printing has become increasingly significant. Recent advancements in 3D printing technology enable the rapid production of molds and patterns, allowing companies to enhance their research and development processes and quickly respond to changing market demands. This agility not only strengthens local manufacturing but also contributes to a more competitive environment.

Furthermore, the global industrial mold market is projected to see substantial growth in the coming years, driven by the rising demand for high-quality molds and the increasing adoption of automated manufacturing processes. As industries such as aerospace and automotive seek lightweight materials and enhanced manufacturing techniques, metal mold manufacturers are at the forefront of this transformation. With the expected valuation of the 3D printing industry surpassing $40 billion by 2030, the significance of metal mold manufacturing becomes even more pronounced as it aligns with broader manufacturing trends focused on innovation, efficiency, and sustainability.

This chart illustrates the market share of metal mold manufacturers across various industries. The automotive sector leads with 25%, followed closely by consumer electronics at 30%. Understanding these dynamics is crucial for recognizing the significance of metal mold manufacturing in the current production landscape.

When selecting a metal mold manufacturer, several key considerations can significantly impact the success of your manufacturing processes. First and foremost, assess the manufacturer’s experience and expertise in the specific type of mold you require. Companies that have a proven track record in producing high-quality molds will not only ensure durability and precision but also offer valuable insights that can streamline your project.

When selecting a metal mold manufacturer, several key considerations can significantly impact the success of your manufacturing processes. First and foremost, assess the manufacturer’s experience and expertise in the specific type of mold you require. Companies that have a proven track record in producing high-quality molds will not only ensure durability and precision but also offer valuable insights that can streamline your project.

Tip: Always ask for case studies or examples of previous work to gauge their capabilities and reliability.

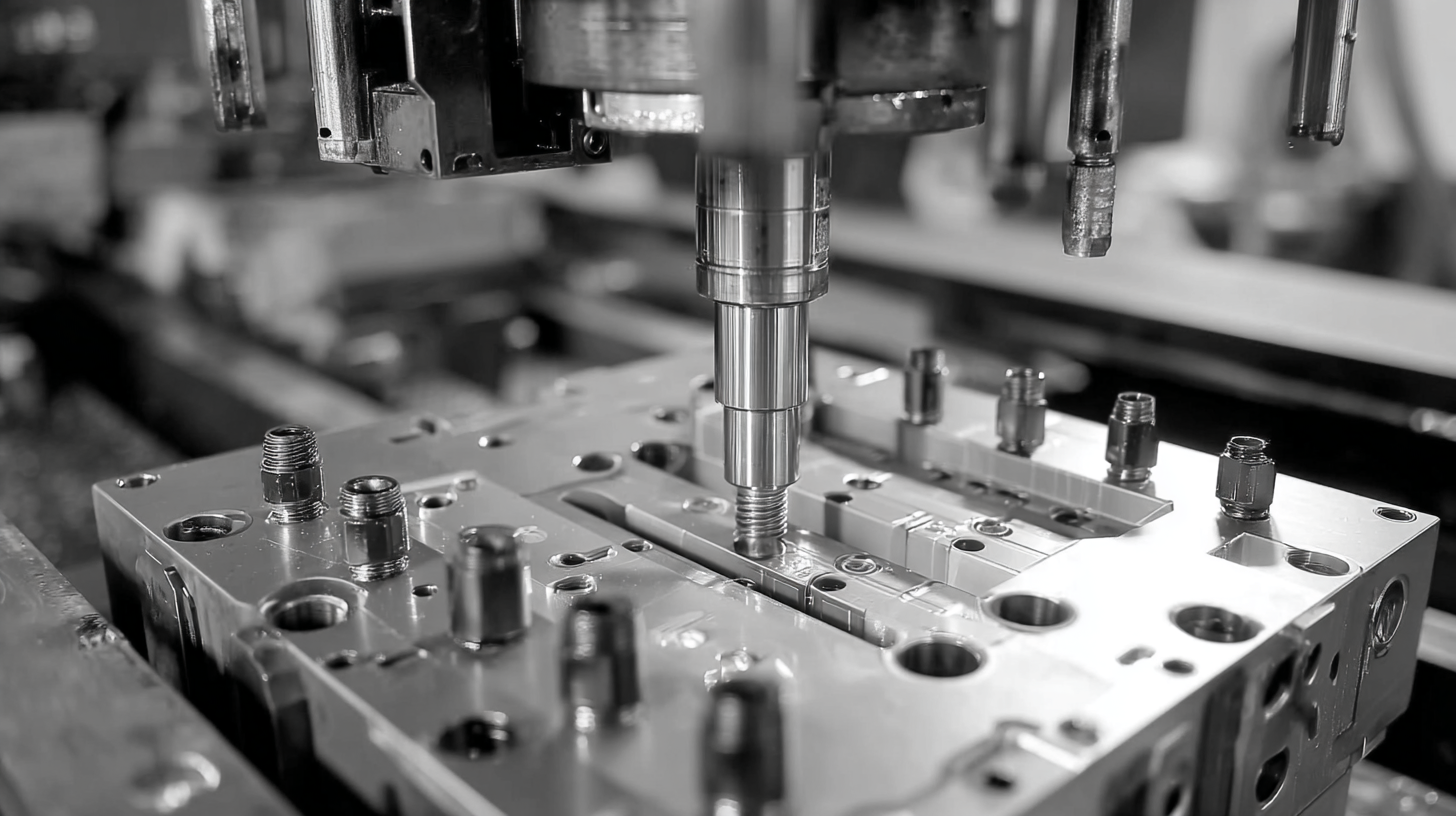

Another important factor to consider is the technology and materials used in the manufacturing process. Advanced machining technology and high-grade materials are crucial for producing molds that can withstand the rigors of modern production demands. Additionally, check if the manufacturer adheres to industry standards and regulations, which can further assure you of their commitment to quality.

Tip: Inquire about the manufacturer's quality control processes to ensure that every mold created meets stringent quality requirements.

Lastly, think about communication and customer support. A responsive manufacturer that collaborates closely with clients can make a significant difference in the overall experience and outcome of your project.

Tip: Establish clear lines of communication and expectations from the outset to foster a productive partnership.

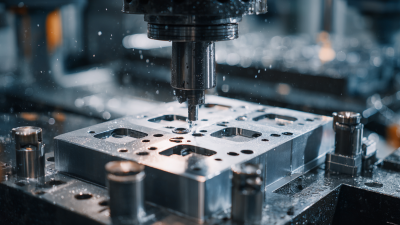

Innovative technologies have significantly transformed metal mold production, making it more efficient and precise. Advanced manufacturing techniques such as 3D printing and computer numerical control (CNC) machining allow for the creation of complex mold designs that were previously difficult or impossible to achieve. These technologies enable manufacturers to produce molds with intricate geometries, reducing lead times and increasing customization options for clients.

Furthermore, the integration of simulation software facilitates performance analysis and optimization of molds before physical production, minimizing errors and material waste.

Additionally, the emergence of smart manufacturing and Industry 4.0 has revolutionized the way metal mold manufacturers operate. By incorporating IoT sensors and data analytics into production processes, manufacturers can monitor machine performance in real-time, predict maintenance needs, and optimize production schedules. This level of connectivity not only enhances operational efficiency but also ensures higher quality standards by reducing variations in the production process. Through these innovative technologies, metal mold manufacturers play a crucial role in shaping the future of manufacturing, driving greater efficiency and fostering creativity in product development.

Quality control is a critical aspect of metal mold manufacturing, ensuring that molds meet the required specifications and tolerances essential for high-quality production. The American Society for Quality (ASQ) emphasizes that implementing rigorous quality control measures can reduce defects by up to 50%. This reduction not only enhances the efficiency of manufacturing processes but also minimizes waste and costs associated with rework and product recalls.

Key quality control measures include regular inspections during various stages of the manufacturing process, the use of advanced testing equipment, and adherence to industry standards such as ISO 9001. According to a report by the International Organization for Standardization (ISO), companies that implement standardized quality management systems see an average improvement in customer satisfaction ratings by approximately 20%. Furthermore, employing skilled personnel to oversee quality assurance processes ensures that any deviations from the norm are promptly addressed, thereby maintaining the integrity of the manufacturing cycle and enhancing overall product reliability.

The metal mold manufacturing industry is witnessing significant changes driven by technological advancements, sustainability goals, and evolving market demands. Automation is at the forefront of this transformation, enhancing production efficiency and precision in metal mold creation. Companies are increasingly adopting robotics and advanced machining techniques that reduce production times and minimize material waste. This trend not only boosts productivity but also aligns with the industry's shift towards green manufacturing practices.

Moreover, as manufacturers strive to meet sustainability targets, there is a growing emphasis on using eco-friendly materials and processes. This includes implementing recycling practices and utilizing energy-efficient machinery. The combination of these technological innovations and sustainable practices is set to propel the market growth in metal mold manufacturing. As the sector adapts to these future trends, companies that embrace both technology and environmental responsibility will likely gain a competitive edge in the rapidly evolving manufacturing landscape.

| Dimension | Current State | Future Trends | Impact on Industry |

|---|---|---|---|

| Technology Integration | High precision CNC machines, CAD/CAM software usage | Increased automation, AI integration for design optimization | Improved efficiency and cost reduction in production |

| Materials Used | Primarily steel and aluminum alloys | Adoption of advanced composites and sustainable materials | Enhanced product performance and environmental sustainability |

| Customer Needs | Demand for custom molds, quicker turnaround times | Shift towards on-demand manufacturing and rapid prototyping | Greater client satisfaction and market responsiveness |

| Workforce Development | Skilled labor shortage in traditional machining | Emphasis on STEM education, training in advanced technologies | Increased innovation and competitiveness in the sector |

| Market Dynamics | Global competition driving quality and cost efficiencies | Emergence of localized production strategies | Stronger local supply chains and reduced lead times |