In the ever-evolving landscape of modern manufacturing, metal stamping emerges as a crucial process. This technique transforms metal sheets into precise components for various industries. As businesses strive for efficiency, understanding the benefits of metal stamping becomes essential.

Metal stamping offers numerous advantages that can enhance productivity and reduce costs. It enables the production of intricate shapes and designs with remarkable precision. Furthermore, the process can significantly speed up production times. However, many businesses still overlook its potential. Not all companies fully embrace this technology, losing out on competitive edges.

Investing in metal stamping can lead to substantial long-term gains. Companies have reported reduced waste and increased material utilization. Nonetheless, some may hesitate, fearing initial setup costs. Balancing risk and reward is key in this decision-making process. By considering the positive impacts, businesses can unlock new opportunities in their manufacturing ventures.

Metal stamping is a widely used manufacturing process. It involves shaping metal sheets into desired forms. Businesses across various sectors can benefit from this technique. Understanding metal stamping can enhance your production efficiency. It's crucial to grasp the fundamentals of this process.

One of the main benefits is precision. Metal stamping yields exact parts, reducing waste. This accuracy is vital for companies that require tightly fitting components. Speed is another factor to consider. Stamping operations are typically faster than traditional methods. However, it’s essential to have skilled workers in place.

Tips for successful metal stamping include regular maintenance of machines. This can prevent costly downtime. Additionally, communicate with your design team. Ensure designs are suitable for stamping. Testing prototypes can reveal flaws early on. Pay attention to the materials used as well. The right metal can dramatically improve overall results. Some businesses may overlook this, leading to subpar outcomes. Reflecting on these aspects is key for long-term success.

Metal stamping is a manufacturing process with notable cost-saving benefits. Businesses can significantly reduce production costs by using metal stamping for various parts. The process involves shaping metal sheets with precision tools. This method utilizes raw materials efficiently, minimizing waste. Each stamped part is consistent and uniform, reducing the need for extensive quality checks.

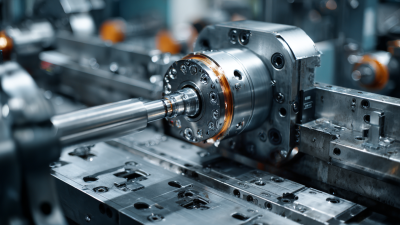

The initial setup may seem costly, but the long-term savings outweigh these expenses. A well-implemented metal stamping system increases production speed. This efficiency can significantly lower labor costs over time. Additionally, the automation involved can lead to fewer errors, further cutting costs. However, businesses must reflect on their equipment and training investments.

Despite the numerous advantages, challenges exist. Companies must ensure that they have skilled operators. Inexperienced workers may lead to mistakes, making production less efficient. Regular maintenance of equipment is crucial. Neglecting this can result in breakdowns and costly repairs. Balancing these factors is key to maximizing cost efficiency in metal stamping.

Metal stamping offers significant advantages for various industries. Precision is one of the standout features of this process. It enables manufacturers to create intricate shapes and sizes. High-quality metal parts lead to fewer defects. This also results in better product reliability. With consistent results, businesses can meet strict quality standards.

Another vital aspect is consistency in production. Metal stamping ensures each piece is nearly identical. This uniformity plays a critical role in assembly lines. Products fit together effortlessly, minimizing production bottlenecks. However, achieving this level of precision demands rigorous quality control. Minor discrepancies can lead to setbacks. It’s essential to invest time in testing and adjustments.

Quality parts can enhance customer satisfaction. They reduce maintenance issues and increase lifespan. Yet, choosing the right materials and techniques can be challenging. It requires careful consideration to avoid pitfalls. Manufacturers must continuously seek improvements in their processes. This ongoing reflection can lead to better outcomes. Ultimately, the advantages of metal stamping are immense, but the journey to perfection is ongoing.

Metal stamping is revolutionizing the manufacturing landscape. This technique speeds up the production process significantly. According to a study by Smithers Pira, businesses using metal stamping can increase their output by nearly 100% compared to traditional methods. This rapid production capability allows firms to meet rising consumer demands without compromising quality.

The efficiency of metal stamping lies in its ability to produce complex parts quickly. Many manufacturers report a reduction in lead times by over 25%. This enables them to respond faster to market trends. With machine advancements, setups and adjustments take less time than ever. However, some operations still encounter challenges. For instance, potential material waste during the stamping process can lead to unexpected costs.

Moreover, while metal stamping offers economic benefits, initial investment costs can be daunting. Smaller businesses may hesitate to adopt this technology due to budget constraints. Nevertheless, the long-term savings and productivity gains often outweigh these initial expenses. Balancing these factors is crucial for any business considering a transition to metal stamping.

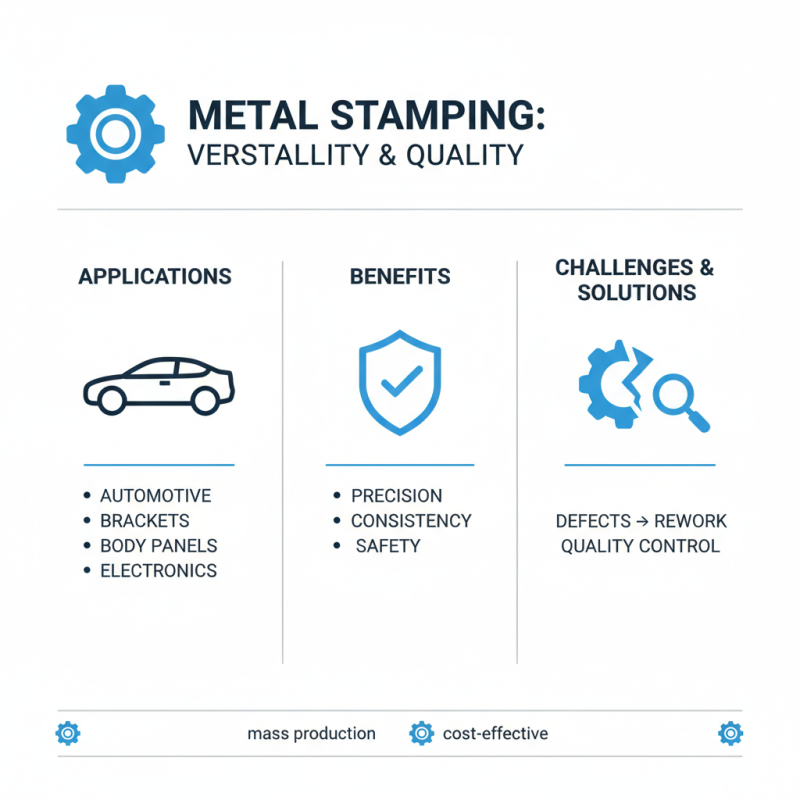

Metal stamping is a highly versatile process, finding applications in a wide array of industries. Automotive manufacturers, for instance, heavily rely on it for creating various parts. From brackets to body panels, metal stamping ensures precision and consistency. This reliability helps in maintaining high safety standards. Yet, sometimes defects can occur, leading to rework. This requires effective quality control measures.

In the electronics sector, metal stamping is crucial for producing connectors and housings. These components need to be made with accuracy to ensure compatibility. However, the need for quick turnarounds sometimes compromises quality. It’s a continuous challenge that requires careful balance. Similarly, in the appliance industry, metal stamping aids in creating robust components. But, if the designs are not well thought out, it can lead to production issues. Embracing versatility in metal stamping can open doors but also demands a commitment to refinement and improvement.