In today's manufacturing landscape, understanding "machining services" is crucial for success. Renowned expert John Smith often emphasizes, "Precision makes the difference." This reflects the importance of quality in machining.

Machining services encompass a range of processes. From turning to milling, each service has its nuances. For example, CNC machining allows for rapid production of complex parts. However, not all services suit every project. Clients may find it challenging to choose the right option.

The right machining services can significantly impact product quality and cost. Mistakes can lead to wasted materials and increased expenses. Companies must evaluate their needs carefully before deciding. Reflecting on which services align best with their goals is essential for growth.

Machining services play a crucial role in modern manufacturing. With advancements in technology, various options are available. Each service has its unique strengths and applications. Understanding these can help businesses optimize their production processes.

CNC machining is highly popular. It offers precision and repeatability. This technology uses computer-controlled tools. Parts can be produced in large quantities with minimal error. However, the setup time can be significant. It’s essential to ensure that the design is flawless before production begins.

Another service is turning. This process shapes materials by rotating them against a cutting tool. It's efficient for cylindrical parts. While effective, it might not suit complex geometries. Wire EDM is worth mentioning too. It can create intricate shapes without exerting pressure on the material. However, it often takes longer and can be costly. Evaluating these services critically allows manufacturers to choose wisely.

| Service Type | Applications | Materials Used | Precision Level | Production Volume |

|---|---|---|---|---|

| CNC Machining | Automotive, Aerospace | Aluminum, Steel | High Precision | Low to Medium |

| Injection Molding | Consumer Products, Medical Devices | Plastics | Moderate Precision | High Volume |

| Laser Cutting | Signage, Fabrication | Metal, Wood | High Precision | Medium |

| 3D Printing | Prototype Development, Custom Parts | Plastic, Metal, Resin | Variable Precision | Low |

| Waterjet Cutting | Aerospace, Architectural | Stone, Glass, Metal | Moderate Precision | Medium |

| EDM (Electrical Discharge Machining) | Tooling, Die Making | Conductive Metals | High Precision | Low to Medium |

| Powder Coating | Finish Coating, Auto Parts | Metal | N/A | High Volume |

| Metal Stamping | Automotive, Appliances | Steel, Aluminum | Moderate to High Precision | High Volume |

| Casting | Heavy Equipment, Automotive | Iron, Aluminum | Variable | Medium to High |

CNC machining stands at the forefront of modern manufacturing. This technology allows for precision and efficiency, highly valued in production processes. A report by Mordor Intelligence highlights that the CNC machining market is expected to reach $100 billion by 2025. Companies are increasingly adopting CNC services to improve productivity while reducing errors.

Tips for implementing CNC machining: Ensure your designs are optimized for machining. This can prevent costly mistakes. Regular maintenance of CNC machines is crucial. It enhances their lifespan and performance. In 2022, statistics indicated that a well-maintained CNC machine can operate up to 20% more efficiently than one that isn't regularly serviced.

Despite the advantages, CNC machining does have its challenges. The learning curve for operators can be steep. Poor programming can lead to material wastage and increased costs. Companies need to invest time in training and aptly utilizing software to avoid these pitfalls. Creating a culture of continuous improvement can help in overcoming such issues. Embracing both the benefits and the potential downfalls is key in making the most of CNC machining.

Additive manufacturing is truly reshaping the landscape of traditional machining. Unlike conventional methods, additive manufacturing builds objects layer by layer. This approach allows for complex geometries that were once impossible to achieve. Designers can create intricate shapes without the constraints of standard tools. It's a game-changer for industries like aerospace and healthcare.

Many businesses are still hesitant to fully embrace this technology. Challenges remain, such as materials' limitations and production speed. Some materials can be expensive or not suitable for all applications. There are ongoing debates about the quality of additive products versus machined ones. It is crucial to acknowledge these shortcomings while exploring new possibilities. Despite the hurdles, additive manufacturing holds promise for innovation and efficiency in machining processes. Organizations that adapt may gain a competitive edge in their fields.

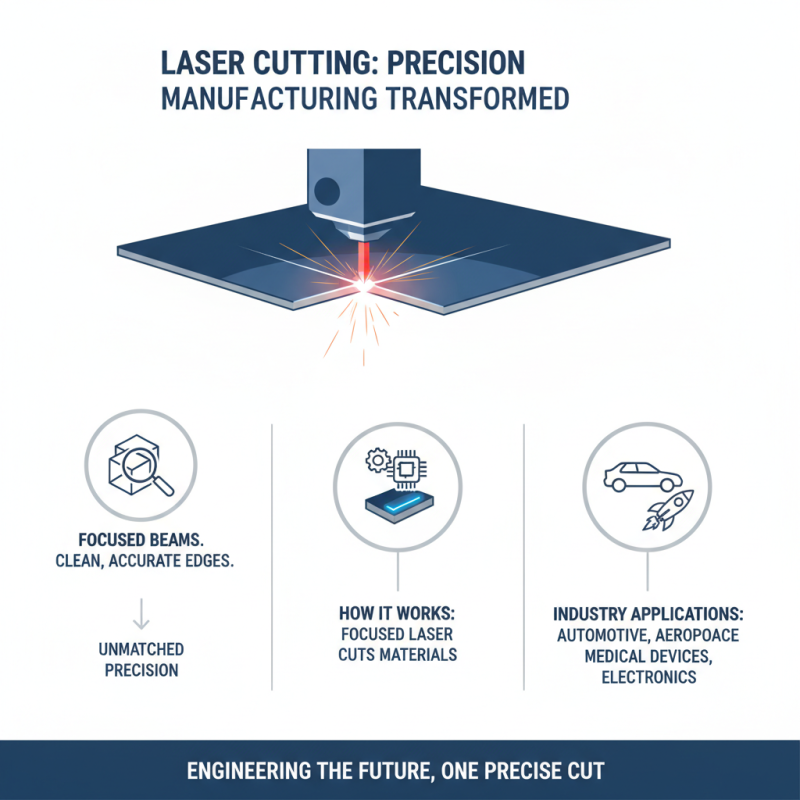

Laser cutting has transformed how industries approach precision manufacturing. This technology uses focused laser beams to cut materials. The result is clean and accurate edges, which are essential in many applications. Industries benefit significantly, from automotive to aerospace, where precision is critical.

In the automotive sector, laser cutting shapes metal parts with remarkable accuracy. It helps reduce waste and improves the overall efficiency of production. However, some smaller companies may struggle to adopt this technology due to high initial costs. The textile industry also utilizes laser cutting for intricate designs. It allows for rapid prototyping and can create one-of-a-kind patterns. Yet, mastering this technology requires skilled operators, which can be a challenge.

Laser cutting's versatility is impressive. It can handle materials like plastics, wood, and composites. Each application brings unique advantages, but it is not without limitations. Some materials may reflect the laser, affecting the cut quality. Additionally, safety measures must be prioritized to protect workers. This reflection on its limitations fosters innovation and improvement in laser cutting techniques.

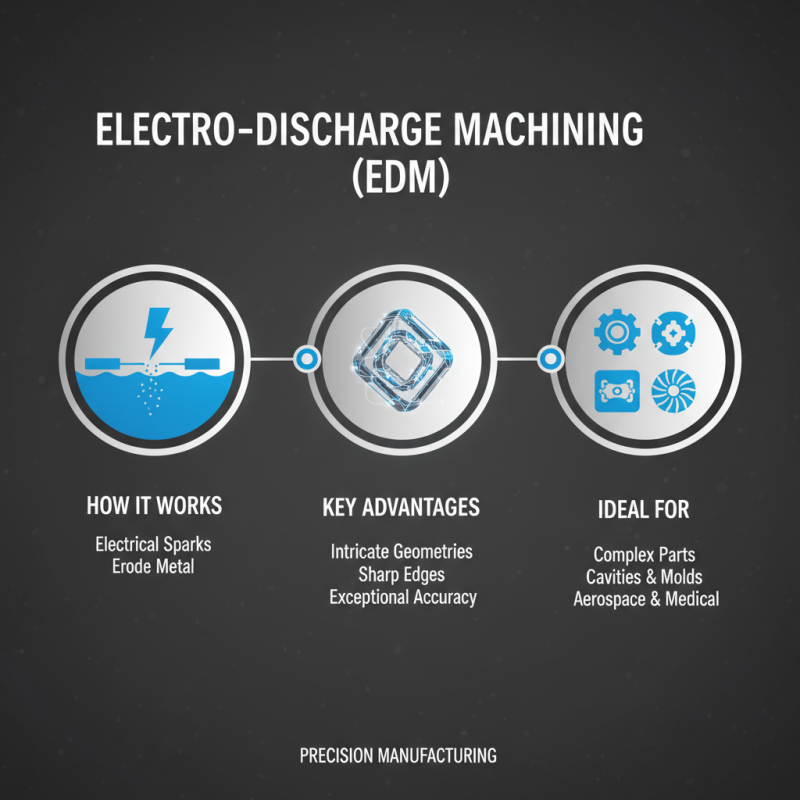

Electro-Discharge Machining (EDM) is a vital technique for crafting intricate metal parts. It uses electrical sparks to erode material, allowing manufacturers to achieve complex geometries that traditional methods struggle with. This precision machining process excels in creating parts with fine details, such as cavities and sharp edges. Designers often gravitate towards EDM for parts that require exceptional accuracy.

However, leveraging EDM is not without its challenges. The setup process can be lengthy, necessitating careful planning. Choosing the correct parameters for the operation is crucial. If not done meticulously, the results may fall short. Additionally, the equipment itself can be expensive and require regular maintenance. This investment is significant, and some may question whether the benefits outweigh the costs.

Despite these hurdles, the advantages of using EDM for complex shapes are apparent. It allows for the treatment of hard materials, presenting fewer limitations. The strategy is particularly useful in aerospace and medical industries. Here, the need for precision is non-negotiable. As innovators push the envelope, EDM continues to show how advanced techniques can create the impossible.