In the fast-paced world of manufacturing, optimizing CNC operations is crucial. John Smith, an expert in CNC technology, once stated, "Investing in the right parts for CNC can dramatically improve productivity." His words highlight an important aspect of modern machining. Each element in a CNC machine plays a critical role in overall performance.

Choosing the right parts for CNC can be overwhelming. Some parts may seem minor, yet they significantly influence efficiency. For example, high-quality tool holders enhance precision and extend tool life. However, not everyone recognizes the importance of these components. Mistakes in selection can lead to costly downtime and frustration.

Furthermore, the constant evolution of CNC technology means that staying updated is challenging. Consumers often find themselves behind the curve. They might overlook innovative parts for CNC that boost operations. It's essential to consider both traditional and new offerings and how they fit into existing setups. Without continual assessment, opportunities for enhancement can be missed.

When it comes to maximizing the performance of CNC machines, understanding essential components is crucial. High-quality spindles, for example, improve cutting speed and reliability. According to a recent industry report, machines equipped with advanced spindles can see a productivity boost of up to 30%. These spindles withstand higher loads, translating into fewer breakdowns.

Another key component is the control system. Modern CNC machines feature sophisticated control software, allowing for precise movements and adjustments. A survey revealed that 70% of users who upgraded their control systems reported enhanced machining accuracy. However, not all operators utilize the full capabilities available. Some may overlook programming options that can significantly influence performance.

Lastly, tool holders play a pivotal role. A stable tool holder minimizes vibrations, improving surface finish. Yet, it's common for manufacturers to compromise on this component. Investing in better holders may require a budget review, but the return on quality justifies the expense. Balancing costs with machine efficiency is a challenge many face.

In the world of CNC machining, accuracy is paramount. Many manufacturers experience inefficiencies due to suboptimal parts. Upgrading critical components can significantly enhance precision. Research indicates that improved tooling can increase productivity by nearly 30%. Addressing the quality of tools leads to tighter tolerances and better surface finishes.

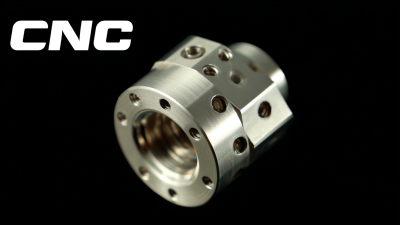

A vital area of focus is the spindle. Upgrading to a high-performance spindle can reduce runout and extend tool life. Studies show that a quality spindle can decrease cycle time by up to 20%. Another essential part is the workholding system. Efficient fixturing minimizes vibration and enhances stability, which directly impacts accuracy. Most operators fail to realize that poor workholding can mitigate the benefits of high-end machinery, leading to wasted resources.

Moreover, investing in advanced control systems can lead to better motion control. Enhanced algorithms ensure smoother operation and reduce wear on components. However, companies often find themselves hesitant to invest in these upgrades due to initial costs. Yet, data suggests that the return on investment can be realized within a year through improved output and fewer defects. Reflecting on these priorities could lead to meaningful advancements in CNC operations.

When it comes to CNC machines, the right accessories can elevate your game. Versatility is key in today's production environment. One critical accessory is a high-quality tool holder. It can significantly improve tool rigidity and minimize vibration, enhancing precision in machining. A robust and flexible holder also allows quick tool changes, making the process more efficient.

Another important part is a coolant system. This often-overlooked element helps keep tools and materials at optimal temperatures. An effective coolant system reduces wear on tools, leading to better finish quality and extended tool life. However, its installation can be tricky, and maintenance demands regular attention. Many users find themselves needing to revisit this aspect frequently.

Additionally, considering a fifth-axis rotary table expands machining capabilities. While this accessory adds complexity, it enables intricate designs. The learning curve can be daunting. Yet, mastering its use often leads to impressive results and new possibilities. Adapting to these accessories can transform operations, but it requires commitment and experimentation. Each piece needs to be integrated thoughtfully for full benefits.

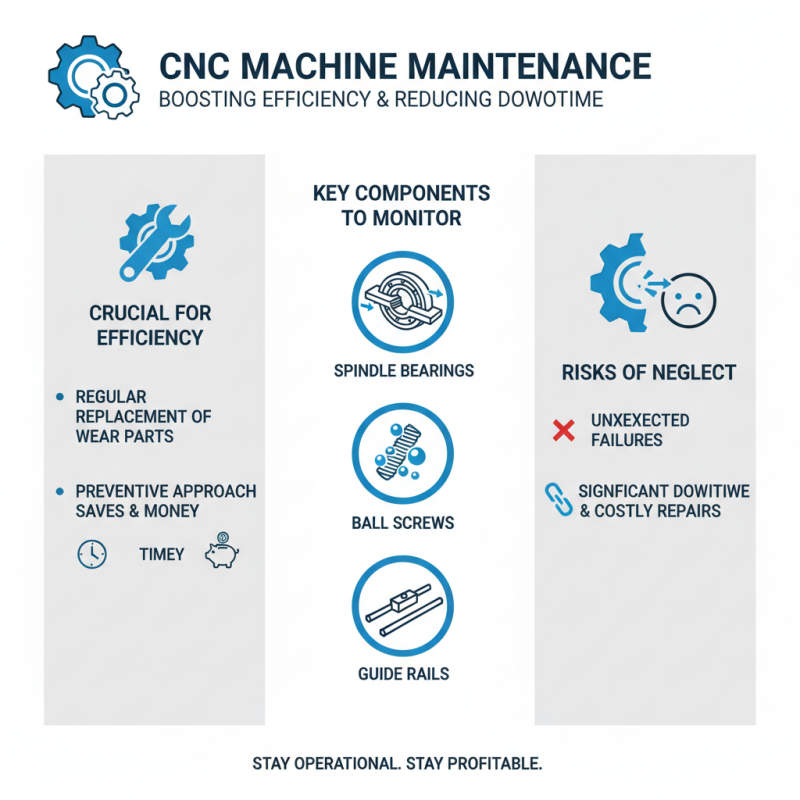

Proper maintenance of CNC machines is crucial. Regularly replacing wear parts can significantly enhance operation efficiency. Items like spindle bearings, ball screws, and guide rails should be on your radar. Many operators overlook these components until they fail, leading to downtime. Preventive approaches can save time and money.

Oil filters often get neglected in maintenance schedules. Clean filters ensure smooth machine operation. Dirty filters can clog systems, causing equipment failure. Inspecting coolant systems is equally important. Not maintaining the right coolant levels can damage machine parts and reduce lifespan.

Consider using vibration analysis tools. They help detect issues before they become serious. Regularly monitoring machine performance is essential. Ignoring small problems can lead to larger, costly repairs. Addressing wear and tear proactively ensures your CNC equipment performs at its best.

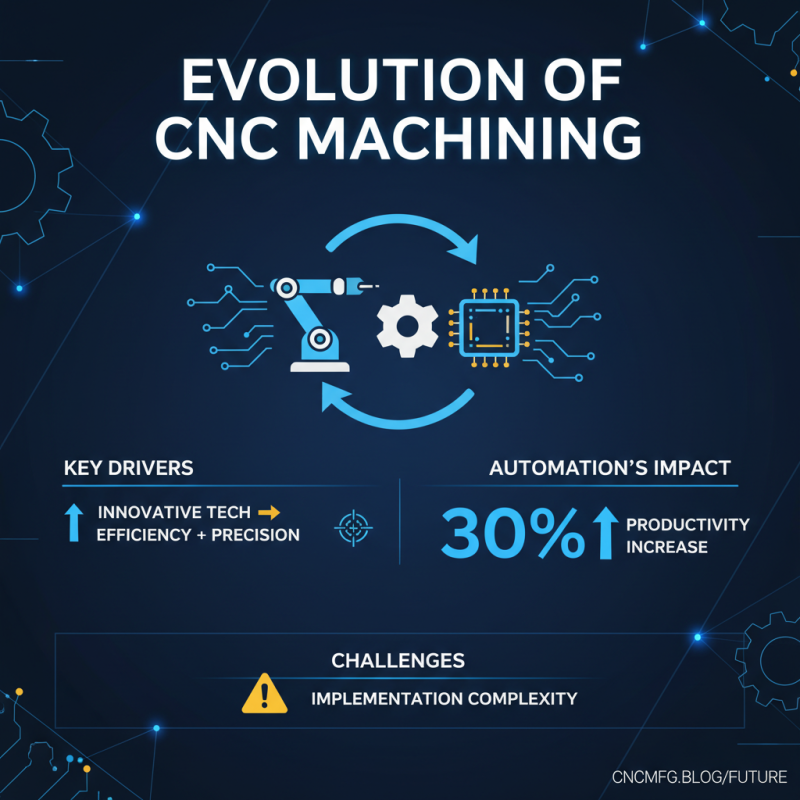

The world of CNC machining is rapidly evolving. Innovative technologies drive efficiency and improve precision. Automation plays a key role in this evolution. It has been shown that automating CNC operations can increase productivity by up to 30%. However, implementing these technologies can be challenging.

Invest in real-time monitoring systems. These systems allow operators to track machine performance continually. Data analytics can reveal patterns. This insight helps in making informed decisions. A report from a leading industry analyst indicates that companies using monitoring technologies see a 25% reduction in downtime. These improvements are crucial for competitiveness.

Another key technology is advanced tool management. Proper tool selection and maintenance are vital. A study found that neglecting tool care can lead to a 15% decrease in machining accuracy. Regularly checking tools improves performance.

Tips: Regular training for operators is essential. Keeping staff updated on new technologies can drive improvement. Encourage a culture of continuous learning. Evaluate technology investments regularly. This ensures alignment with operational goals and minimizes waste.