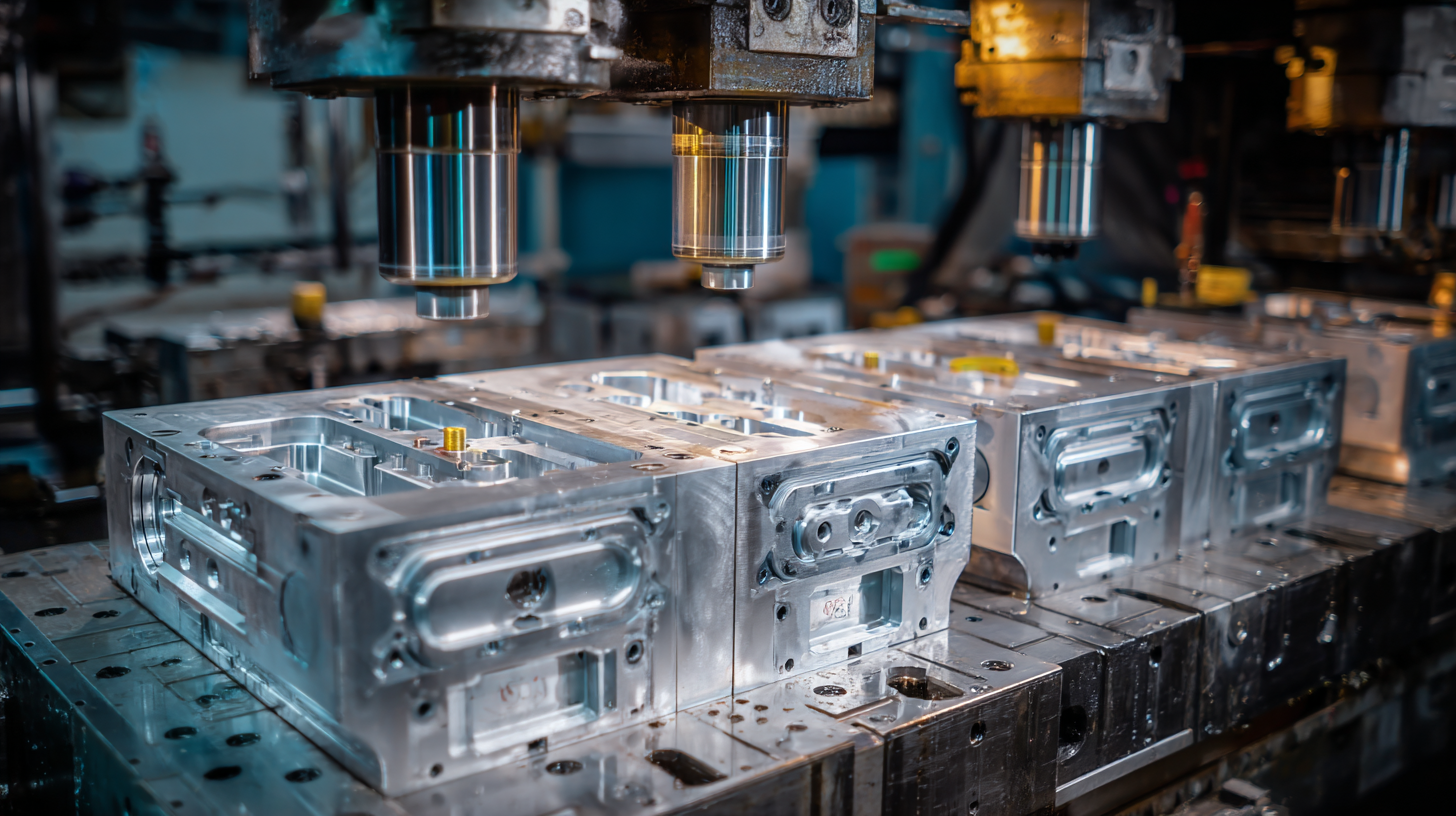

As we look ahead to 2025, the landscape of mold manufacturing is poised for significant transformation driven by innovative solutions to emerging challenges. According to a recent report by MarketsandMarkets, the global mold manufacturing market is expected to reach $27.2 billion by 2025, growing at a CAGR of 5.1% from 2020. This growth is fueled by advancements in automation, materials science, and additive manufacturing technologies, which are reshaping traditional practices.

Furthermore, the rise of Industry 4.0 highlights the importance of digital integration in mold production, enabling manufacturers to enhance efficiency and reduce lead times. Amid this evolution, understanding the latest trends and comparing innovative solutions will be pivotal for businesses aiming to thrive in a competitive marketplace.

As we explore the various facets of mold manufacturing, it is essential to consider both the inherent challenges and the innovative paths forward that will define the industry.

As the mold manufacturing industry evolves, after-sales service has become a pivotal factor in enhancing customer satisfaction. According to a recent report by MarketsandMarkets, the global mold manufacturing market was valued at approximately $34 billion in 2023 and is projected to reach $47 billion by 2025, indicating significant growth opportunities. This growth is largely driven by increased demand for precision-engineered products and the growing trend of high-volume production. Companies that prioritize robust after-sales service strategies are likely to gain a competitive edge, ensuring long-term customer loyalty.

Enhanced customer satisfaction can be achieved through various innovative after-sales service strategies. For instance, utilizing advanced technologies such as AI-driven chatbots and predictive maintenance software not only streamlines the service process but also reduces downtime. According to a study from Deloitte, companies that implement proactive after-sales services can increase their customer retention rates by up to 80%. Providing real-time support and comprehensive training can further elevate the customer experience, making it essential for mold manufacturers to adapt their services to meet the evolving needs of their clients. Emphasizing after-sales service as a core element of business strategy will not only enhance customer satisfaction but also drive sustainable growth in the competitive landscape of mold manufacturing.

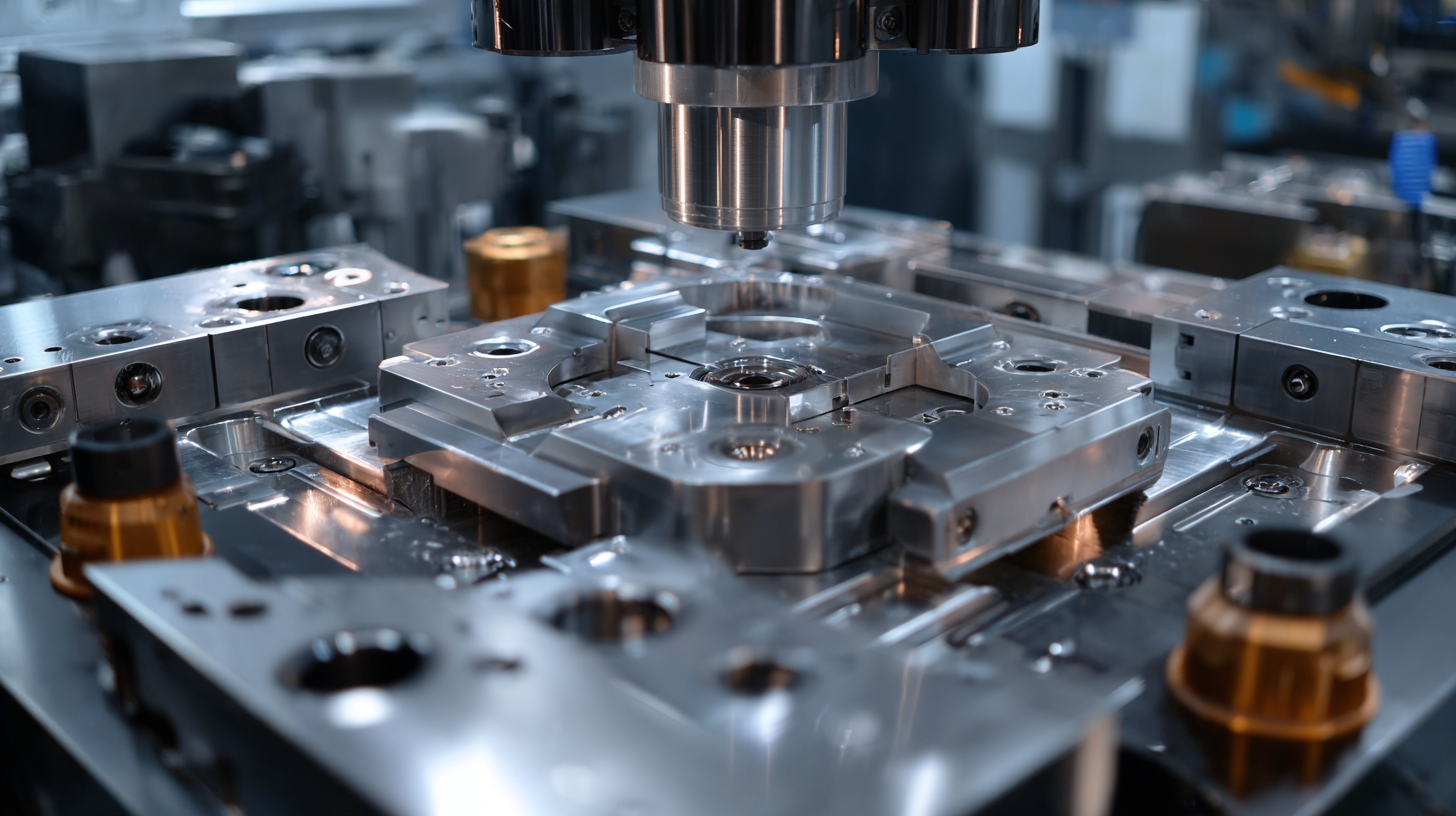

Innovative solutions for mold repair and replacement are crucial as companies seek to reduce maintenance costs in the coming years. With rising operational expenses, businesses must embrace advanced technologies, like additive manufacturing, to enhance efficiency and minimize waste. This manufacturing approach not only speeds up the production process but also significantly lowers costs associated with traditional mold manufacturing and repairs.

Innovative solutions for mold repair and replacement are crucial as companies seek to reduce maintenance costs in the coming years. With rising operational expenses, businesses must embrace advanced technologies, like additive manufacturing, to enhance efficiency and minimize waste. This manufacturing approach not only speeds up the production process but also significantly lowers costs associated with traditional mold manufacturing and repairs.

One effective tip is to incorporate regular inspections using advanced technologies like drone inspections. This can help identify potential issues before they escalate, ensuring molds are maintained in optimal condition. Additionally, leveraging generative AI can streamline the design and production processes, leading to innovative mold solutions that reduce the likelihood of costly repairs.

Furthermore, investing in employee training on new technologies and processes can foster an atmosphere of innovation. Empowering your workforce with knowledge about the latest tools allows for better problem-solving and proactive maintenance strategies. Embracing these changes can position companies to tackle challenges head-on while achieving significant cost savings in mold maintenance and production.

As we look towards 2025, the landscape of mold manufacturing is continually evolving, particularly in response to the growing demand for innovative after-sales strategies. Successful global mold firms are now leveraging advanced technologies and customer-centric approaches to enhance their after-sales service, thereby ensuring customer satisfaction and loyalty. One notable case study involves a leading manufacturer that implemented a proactive maintenance program, allowing clients to minimize downtime and extend the lifespan of their molds. This approach not only reinforced customer trust but also established a steady channel for repeat business.

Another compelling example comes from a multinational mold company that adopted a comprehensive digital platform for customer engagement. This platform facilitates streamlined communication between the firm and its clients, enabling real-time updates on product performance and maintenance schedules. By providing tailored support and transparent data, this company successfully reduced response times to customer inquiries, resulting in an impressive increase in overall customer satisfaction. As these case studies illustrate, embracing innovative after-sales strategies is crucial for mold manufacturers aiming to thrive in an increasingly competitive market.

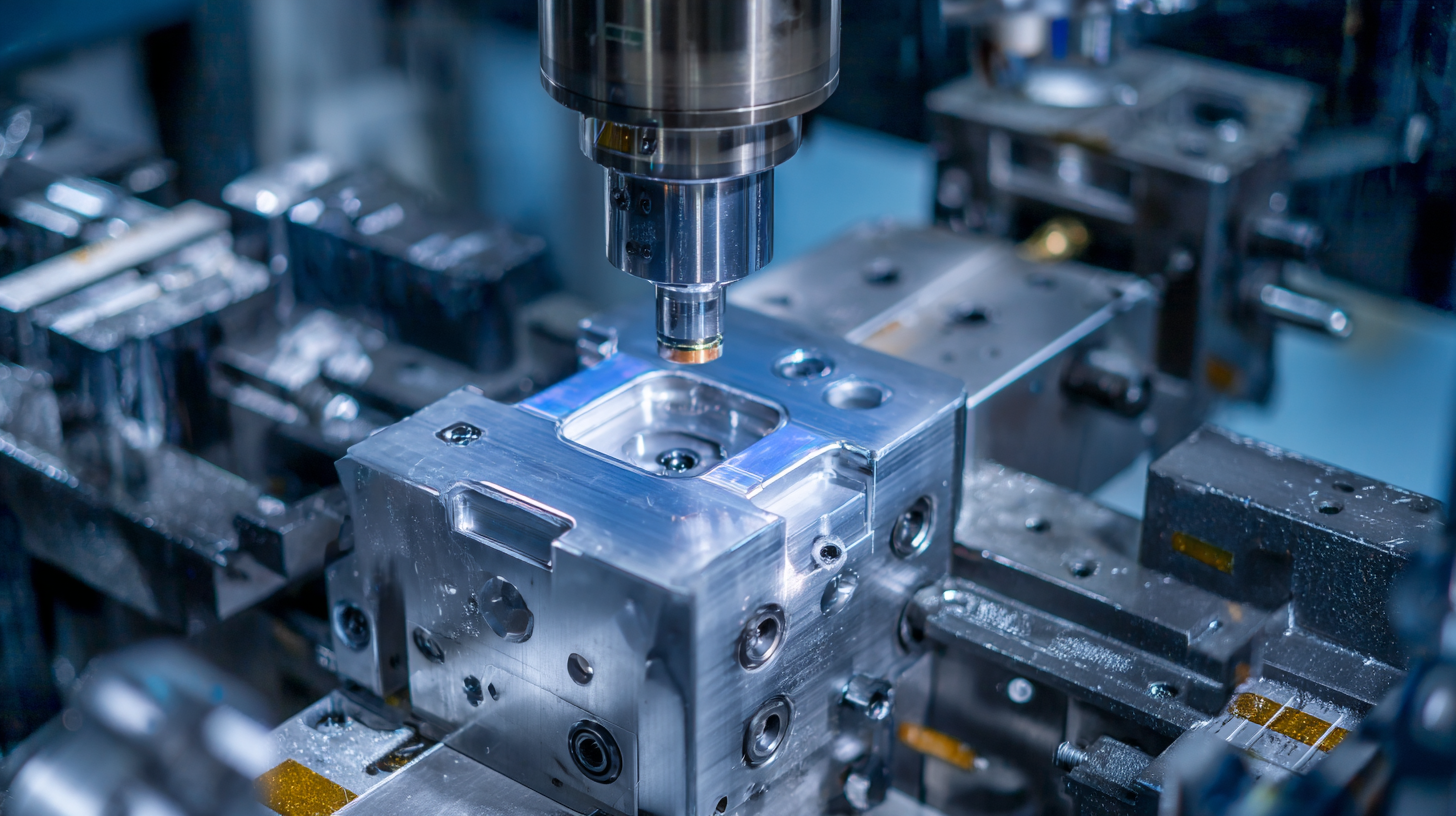

As we move toward 2025, the integration of predictive maintenance technologies into mold manufacturing is set to redefine the landscape of the industry. According to a recent report by McKinsey & Company, predictive maintenance can reduce equipment downtime by 30% to 50%, ultimately extending mold lifespan and enhancing cost efficiency. By leveraging advanced analytics and IoT sensors, manufacturers can proactively identify wear and tear on molds, allowing for timely interventions that prevent costly breakdowns and extend the operational life of their equipment.

To maximize the benefits of predictive maintenance, consider implementing a comprehensive data collection strategy. Regularly monitor key performance indicators (KPIs) such as mold cycle times and temperature fluctuations. These metrics not only provide insights into mold health but also help in planning maintenance schedules that minimize disruptions. Another crucial tip is to invest in training for your workforce; ensuring that employees are well-versed in utilizing these technologies will enhance overall productivity and responsiveness to potential issues.

The shift toward predictive maintenance is not merely a trend but a strategic response to the rising costs of mold manufacturing and maintenance. A study from Deloitte indicates that firms utilizing predictive analytics can save up to 20% on maintenance costs annually. Therefore, adopting these innovative solutions will not only foster a more sustainable manufacturing process but will also secure a competitive edge in a rapidly evolving market.

In 2025, the landscape of mold manufacturing is set to dramatically transform as companies increasingly embrace digital solutions. These innovations will not only enhance service delivery but also enable manufacturers to stay competitive in an ever-evolving market. By leveraging technologies such as IoT, AI, and automation, businesses can optimize their processes, reduce waste, and improve precision in mold production.

Tips for embracing digital solutions include investing in training programs for employees to familiarize them with new technologies. Additionally, consider collaborating with technology partners who specialize in mold manufacturing solutions to stay ahead of the curve. Keeping up with industry trends can also provide insights into effective digital tools that can streamline operations and foster innovation.

As organizations adopt these future-proofing strategies, they must also prioritize data security to protect sensitive information. Implementing robust cybersecurity measures and conducting regular audits will help ensure that digital transitions do not compromise business integrity. By proactively addressing these challenges, mold manufacturers can maximize the benefits of digitalization while mitigating potential risks.