In the competitive landscape of manufacturing, the design of an effective press mold plays a crucial role in achieving optimal production efficiency. According to a report by the Society of Manufacturing Engineers, companies that invest in advanced mold design techniques can increase production rates by up to 30% while reducing material waste by as much as 25%. The quality of a press mold directly influences cycle times and finish quality, which in turn impacts overall operational costs. As the demand for precision and high-volume production continues to rise, mastering the art of press mold design is not just beneficial but essential for staying ahead in the industry. This guide will provide invaluable insights into the best practices for designing press molds that enhance efficiency, streamline processes, and ultimately deliver superior products.

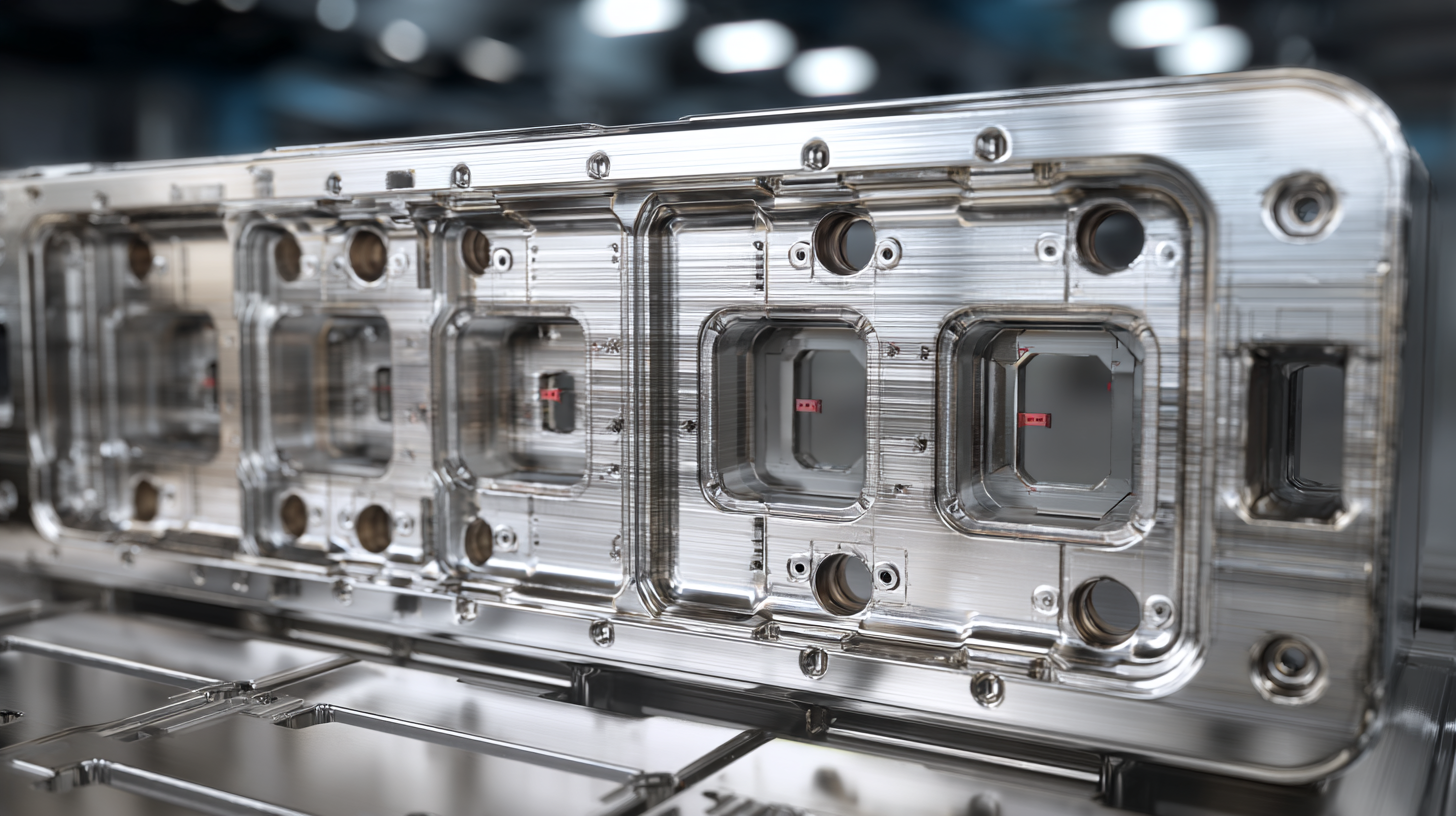

When it comes to optimizing production efficiency in manufacturing, understanding the various types of press molds is crucial. Different mold types, such as single cavity, multi-cavity, and family molds, each have unique advantages and disadvantages. A comparative analysis of these mold types reveals insights into their design and application. For instance, single cavity molds may offer simplicity and lower initial costs, while multi-cavity molds are designed for mass production, significantly enhancing efficiency by reducing cycle times. Choosing the right mold type is vital in aligning with production goals and maximizing output.

As industries evolve and technology advances, manufacturers are increasingly adopting innovative designs that push the boundaries of traditional mold-making. The latest developments in the field, akin to how groundbreaking technologies emerge in artificial intelligence, demonstrate that continuous improvement in mold design can lead to substantial gains in efficiency. Analyzing the impact of materials, cooling systems, and the integration of advanced modeling techniques can pave the way for smarter, more effective press molds. This holistic understanding enables manufacturers to stay competitive and meet the demands of an ever-changing market landscape.

Designing an efficient press mold is crucial for maximizing production output and minimizing costs in manufacturing processes. According to a 2020 report by Technavio, optimizing mold design can lead to a reduction in cycle time by up to 30%, significantly enhancing overall production efficiency. Factors such as material selection, cooling channel configuration, and mold geometry play pivotal roles in determining the final product's quality and the speed of production. For instance, using advanced materials like aluminum instead of steel can decrease thermal conductivity issues and facilitate quicker cooling, thereby reducing cycle times.

Another essential factor influencing press mold efficiency is the integration of simulation technologies during the design phase. A study by MIT indicates that using digital twins and simulation software can reduce molding errors by as much as 25%, providing manufacturers with valuable insights into potential pitfalls before physical production begins. Additionally, effective maintenance schedules and regular inspections can prevent costly downtimes, with a report from the National Association of Manufacturers highlighting that predictive maintenance can improve operational efficiency by up to 20%. By focusing on these key factors, manufacturers can significantly enhance their press mold designs and ensure sustainable production practices.

When designing a press mold, material selection plays a crucial role in determining the overall performance and efficiency of the production process. The right material not only influences the strength and durability of the mold but also impacts the cost-effectiveness of the manufacturing operation. Common materials used for press molds include steel, aluminum, and composite materials, each offering unique benefits and limitations.

Steel molds are renowned for their exceptional strength and longevity, making them ideal for high-volume production runs. However, they can be quite costly, both in terms of initial investment and maintenance. Aluminum molds, on the other hand, offer a more lightweight alternative with quicker thermal conductivity, which can enhance cycle times. Their lower cost and ease of machining make them suitable for prototyping or smaller production volumes, but they might not withstand the same level of wear as steel.

Composite materials provide a balance between strength and cost, often used when high durability is needed without the weight of metals. While they may not match steel's hardiness, advancements in technology have significantly improved their performance. Ultimately, choosing the right material for your press mold depends on the specific production needs, expected output, and budget constraints, making it essential to evaluate each option carefully to optimize production efficiency.

Designing effective press molds is crucial for maximizing production efficiency in various manufacturing processes. One of the key design considerations involves the incorporation of advanced cooling systems. Case studies have shown that the use of conformal cooling systems can significantly enhance the thermal performance of press molds. For instance, recent data indicates that these systems can reduce cycle times by up to 30%, leading to increased throughput and improved part quality.

Tip: When designing your press mold, consider implementing conformal cooling channels that closely follow the mold’s contours. This not only optimizes temperature control but also minimizes temperature gradients that can lead to defects in molded parts.

Moreover, the integration of sustainable materials in the design process is gaining traction. As highlighted in recent studies, the shift towards sustainable building materials is driven by technological innovations that improve performance and reduce environmental impact. By evaluating the performance of these materials through real-world case studies, manufacturers can make informed decisions that support both efficiency and sustainability.

Tip: Always assess the latest advancements in materials science to ensure your press mold design incorporates the best available sustainable solutions, thereby enhancing both efficiency and environmental responsibility.

In today’s manufacturing landscape, the integration of innovative technologies is essential for optimizing production efficiency, particularly in the realm of press mold design. Among these advancements, 3D printing has emerged as a transformative force, enabling manufacturers to create complex molds with unparalleled precision and speed. This additive manufacturing process allows for the rapid prototyping of mold designs, reducing lead times and minimizing material waste, ultimately resulting in cost-effective production cycles.

When comparing best practices in press mold production, the adaptability offered by 3D printing stands out as a key advantage. Traditional methods often require extensive machining and manual adjustments, which can be time-consuming and prone to errors. In contrast, 3D printing streamlines this process by allowing designers to iterate quickly and implement changes on-the-fly. This capability not only enhances the quality of the molds but also ensures that manufacturers can respond swiftly to market demands, making it a critical component of modern manufacturing strategies. Embracing such innovative practices empowers companies to stay ahead of the competition by maximizing their operational efficiency and product quality.