The integration of die technology within 3D printing is set to revolutionize manufacturing processes across various industries. According to a report by Mordor Intelligence, the global 3D printing market is projected to reach $34.8 billion by 2026, with a significant focus on automotive and aerospace applications. The complexity and precision required in die manufacturing can greatly benefit from the unique capabilities of 3D printing, allowing for the production of intricate designs with less waste and reduced production times. In this context, the combination of traditional die techniques with advanced 3D printing methodologies presents an opportunity to enhance productivity and innovation. As we delve deeper into the potential future applications of dies in 3D printing technology, it becomes evident that the intersection of these two fields is not only inevitable but also essential for achieving greater efficiencies and capabilities in the manufacturing landscape.

Die technology plays a crucial role in advancing 3D printing processes by enhancing precision and efficiency. Traditional 3D printing methods often struggle with consistency and fine detail. However, by integrating die technologies, manufacturers can achieve more accurate replication of complex geometries, ensuring that each printed layer aligns perfectly. This leads to minimized material waste and reduced production costs, thus making 3D printing more economically viable for large-scale applications.

Moreover, the incorporation of die technology facilitates the creation of intricate multi-material components that were previously challenging to manufacture. With the ability to precisely control the deposition of different materials, designers can explore innovative applications that enhance product functionality. This advancement not only broadens the scope of 3D printing applications across industries, including aerospace, automotive, and healthcare, but also positions die technology as a pivotal element in the future of additive manufacturing. As these processes evolve, the synergy between die technology and 3D printing will undoubtedly unlock new possibilities for customization and production efficiency.

| Application Area | Die Technology Role | Benefits | Challenges | Future Trends |

|---|---|---|---|---|

| Aerospace | Precision component manufacturing | Reduced weight, enhanced performance | High material costs | Increased adoption of composite materials |

| Automotive | Prototype and low-volume production | Shorter development cycles | Regulatory challenges | Growth in electric vehicle components |

| Medical Devices | Customized implants and tools | Personalized patient care | Complex regulatory approvals | Bioprinting advancements |

| Consumer Goods | Mass customization | Enhanced customer experience | Supply chain complexities | Sustainability initiatives |

| Jewelry | Intricate designs and prototypes | Unique products at scale | Market competition | Integration of virtual design |

The integration of die techniques into 3D printing applications presents a multitude of key benefits, particularly in enhancing sustainability and efficiency. By adopting natural fiber-reinforced filaments in FDM 3D printing, the industry can significantly reduce environmental impact while providing strong, lightweight materials suitable for various applications. These biocomposite materials not only improve mechanical properties but also contribute to the shift towards more sustainable production methods by minimizing reliance on traditional plastics.

The integration of die methods into 3D printing technology introduces several challenges that must be meticulously addressed to harness their full potential. One significant challenge is ensuring the compatibility between die materials and the 3D printing process, which can vary widely depending on the technology used. For instance, while some printing processes may allow for metal dies, others may require alternative materials that provide sufficient durability and precision. Addressing this issue requires extensive research into various material properties and their behaviors during the printing process to identify optimal combinations.

Another critical challenge lies in the scalability of die integration within existing 3D printing workflows. Many current processes are not designed to accommodate die methods effectively, leading to inefficiencies and increased production times. Developing solutions such as modular die designs and adaptable printing systems can help streamline this integration, allowing for a smoother transition and more efficient use of resources. Additionally, addressing post-processing requirements, such as surface finishing and dimensional accuracy, is vital for ensuring that the final products meet industry standards. By tackling these challenges head-on, the 3D printing industry can unlock new possibilities for innovation and efficiency.

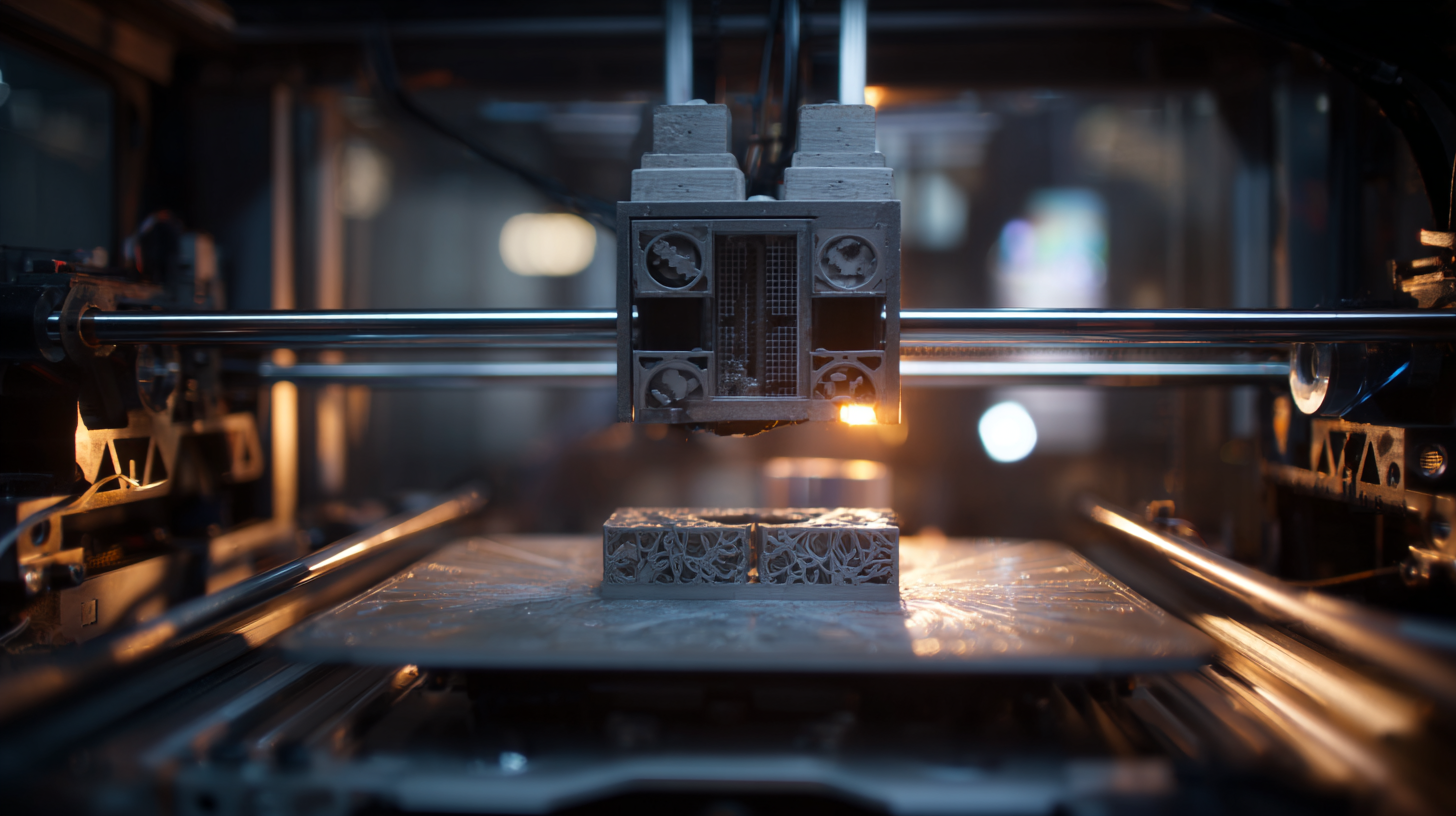

The evolution of die uses in next-gen 3D printing technology is poised to transform various manufacturing sectors. As additive manufacturing techniques advance, the integration of smart dies with advanced sensors and automation will enhance the precision and efficiency of the production process.

With the ability to create intricate geometries and complex structures, 3D printing is enabling designers and engineers to push the boundaries of traditional die-making approaches. These innovations will facilitate the creation of customizable mass production techniques, catering to niche markets and diverse customer demands.

With the ability to create intricate geometries and complex structures, 3D printing is enabling designers and engineers to push the boundaries of traditional die-making approaches. These innovations will facilitate the creation of customizable mass production techniques, catering to niche markets and diverse customer demands.

Future trends also indicate a shift towards sustainability in die applications for 3D printing. Eco-friendly materials and processes will become increasingly important, as industries seek to reduce waste and carbon footprints. Techniques such as digital inventory and on-demand production using 3D printing will allow firms to minimize excess materials and energy consumption.

Moreover, with advances in bioprinting and material science, dies will not only be made from traditional materials but will also incorporate biodegradable options, paving the way for a more environmentally conscious manufacturing sector.

The integration of die technology within 3D printing is reshaping various industries, as evidenced by recent case studies showcasing successful applications. In the medical field, 3D-printed medical models are transforming patient care by providing accurate representations for surgical planning. According to industry reports, the market for medical 3D printing is expected to reach approximately $3.5 billion by 2025, driven by demand for custom solutions and enhanced patient outcomes.

Moreover, the application of 3D printing in engineering and construction is beginning to redefine traditional practices. Notably, advancements in polymer composites used in civil infrastructure demonstrate their potential for durability and weight reduction, with studies indicating a 50% decrease in material costs by utilizing 3D printing technologies. Industries are also exploring sustainable practices, such as the 3D printing of food processing byproducts, which not only minimizes waste but also enriches packaging solutions.

As these examples illustrate, the successful integration of die technology in 3D printing is paving the way for innovative solutions and significant advancements across multiple sectors.