In today's fast-paced manufacturing landscape, the term

"die" holds significant importance as a critical component in shaping and forming materials across various industries.

According to a recent report by the Manufacturing Institute, the global tooling market, which includes dies, is projected to reach

$250 billion by 2025, reflecting a robust growth rate driven by advancements in technology and the increasing demand for precision-engineered components.

Dies play a pivotal role in processes such as stamping, molding, and machining, enabling manufacturers to produce complex parts with high accuracy and efficiency.

As industries continue to evolve, understanding the various types of dies and their applications is essential for optimizing production processes and maintaining competitiveness in the market.

This blog will delve into the different types of dies used in modern manufacturing and their significant contributions to industrial efficiency.

Dies play a pivotal role in processes such as stamping, molding, and machining, enabling manufacturers to produce complex parts with high accuracy and efficiency.

As industries continue to evolve, understanding the various types of dies and their applications is essential for optimizing production processes and maintaining competitiveness in the market.

This blog will delve into the different types of dies used in modern manufacturing and their significant contributions to industrial efficiency.

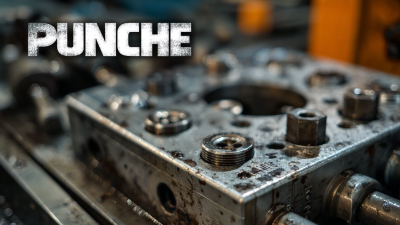

Die design plays a crucial role in modern manufacturing, serving as the blueprint for producing complex shapes and components with precision. A well-crafted die not only ensures the accuracy of the final product but also enhances the efficiency of the manufacturing process. This process involves various considerations, including material selection, geometry, and production volume. Skilled engineers apply advanced technologies and simulations to optimize die design, taking into account the unique requirements of each project.

Additionally, effective die design can significantly reduce production costs and lead times. By incorporating features that facilitate ease of manufacturing and maintenance, manufacturers can achieve a higher return on investment. As industries continue to evolve, the importance of innovative die design cannot be overstated. The integration of modern techniques, such as computer-aided design (CAD) and additive manufacturing, further empowers engineers to create dies that meet the demands of rapidly changing markets, showcasing the vital role that die design plays in the broader landscape of modern manufacturing.

In modern manufacturing processes, dies play a crucial role, serving as tools that shape materials into specific forms. Various types of dies are utilized depending on the manufacturing method employed. For instance, in stamping processes, progressive dies are commonly used to create parts through a series of operations, allowing for high-volume production and precision. Conversely, in molding processes, injection molds are essential for forming complex shapes from thermoplastics.

When selecting a die type, it's important to consider the material being used and the desired end product. Each die type offers unique advantages that can enhance efficiency and quality in production. For example, using a strong die material can significantly reduce wear, extending the life of the die and minimizing downtime.

**Tip:** Always conduct a thorough analysis of the manufacturing requirements before choosing a die type. This includes evaluating the material properties, production volume, and design intricacies. A well-suited die can greatly increase productivity and maintain product consistency, leading to long-term cost savings.

In modern manufacturing processes, the performance and longevity of dies are critical factors that can significantly influence production efficiency and cost. According to a report by the International Journal of Advanced Manufacturing Technology, approximately 30% of total production costs can be attributed to die wear and maintenance. This highlights the necessity for manufacturers to focus on the quality and durability of their dies to reduce downtime and ensure continuous operation.

Several key factors impact die performance, including material selection, surface treatments, and operating conditions. For instance, research shows that high-speed steel (HSS) dies have a wear resistance improvement of up to 60% when coated with titanium nitride (TiN), leading to longer tool life. Additionally, controlling parameters such as temperature and lubrication during the manufacturing process can play a significant role in preserving die integrity. Maintaining optimal conditions not only enhances die longevity but also improves the final product quality, thus reinforcing the importance of strategic planning in die maintenance and operation.

In modern manufacturing, die technologies play a critical role in enhancing production efficiency and product quality. Innovations in die design and material science have led to the development of advanced dies that are more durable and capable of withstanding higher pressures and temperatures. These improvements not only increase the lifespan of the tools but also reduce downtime, allowing manufacturers to optimize their workflows and productivity.

Furthermore, the integration of smart technologies such as sensors and automation into die manufacturing processes has revolutionized the industry. Real-time monitoring systems can provide valuable insights into the die's performance, enabling proactive maintenance and reducing the risk of costly failures. This shift towards data-driven practices ensures that manufacturers can swiftly adapt to changing demands, resulting in a more agile and responsive production environment. As the industry continues to evolve, the emphasis on innovative die technologies will remain pivotal in driving efficiency and competitiveness in modern manufacturing.

| Innovation Type | Description | Efficiency Improvement (%) | Material Compatibility |

|---|---|---|---|

| 3D Printed Dies | Using additive manufacturing techniques to create custom dies. | 30% | Metals, Plastics |

| Smart Dies | Integration of sensors to monitor die performance in real-time. | 40% | Metals, Composites |

| Micro-Textured Dies | Dyes with micro-features to improve material flow and reduce wear. | 25% | Plastics, Rubber |

| High-Performance Alloys | Development of new alloy compositions for extended die life. | 20% | Metals |

| Die Cooling Technologies | Improved cooling systems to control temperature and improve cycle times. | 35% | Metals, Composites |

In modern manufacturing processes, the die plays a crucial role in achieving precision and efficiency. Proper maintenance and troubleshooting of dies are essential to ensure their longevity and optimal performance. Regular inspection can help identify potential wear and tear before it leads to significant issues.

**Tip 1:** Establish a routine maintenance schedule that includes cleaning, lubrication, and thorough inspections. Cleaning removes debris that could affect the die's performance, while lubrication prevents rust and reduces friction during operation.

Even with diligent maintenance, problems may still arise. Quick troubleshooting is essential to minimize downtime. One common issue is misalignment, which can cause defects in the final product. To address this, always check the alignment of the die before production runs.

**Tip 2:** Keep a detailed log of any discrepancies and the steps taken to resolve them. This log will serve as a valuable reference for future troubleshooting and can help identify recurring issues that may require more attention.