As we look ahead to 2025, the "punch die" industry is poised for significant transformation driven by advanced technologies and innovative practices. Industry expert Dr. Henry Larson, a leading figure in metal forming technologies, emphasizes that "the future of punch die manufacturing will be defined by automation and smart technologies that enhance precision and efficiency." These developments are not only reshaping how punch dies are produced but are also setting new standards for operational excellence across the sector.

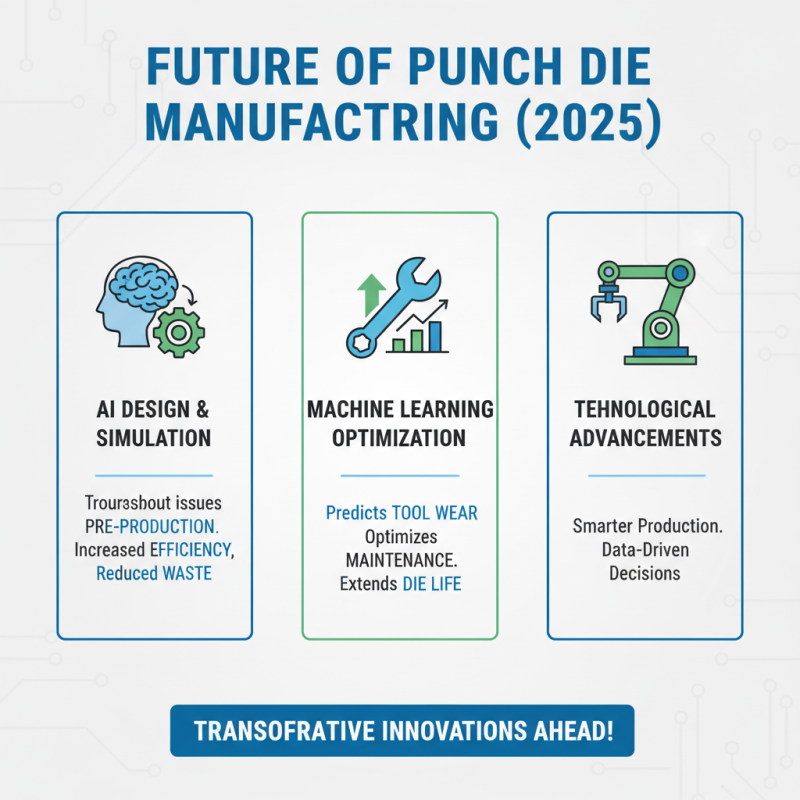

The integration of artificial intelligence and machine learning into punch die design and production processes is one of the most exciting trends. Such innovations promise to minimize waste, reduce lead times, and improve overall product quality. Furthermore, the growing emphasis on sustainability is prompting manufacturers to explore eco-friendly materials and energy-efficient practices, ensuring that the punch die industry adapts to the increasing demand for responsible manufacturing.

As we delve into the emerging trends and innovations that will shape the punch die landscape in 2025, it is essential to understand the implications of these advancements for businesses and consumers alike. The advances in technology and sustainability are not merely trends; they represent a pivotal shift that will ultimately redefine the capabilities and applications of punch die in various industries.

The punch die industry is on the brink of significant transformation as we approach 2025, driven by advancements in technology and shifting manufacturing demands. One of the most notable trends is the increasing integration of automation and robotics into punch die operations. Manufacturers are adopting smart machinery that can execute precise movements and reduce human error, leading to enhanced efficiency and productivity. This shift not only expedites production processes but also allows for the creation of more complex dies that meet the evolving needs of various industries.

Another innovation gaining traction is the use of advanced materials and coatings in punch die fabrication. Companies are exploring high-performance alloys and specialized coatings that enhance durability and reduce wear during operation. These innovations directly contribute to longer die life cycles, resulting in reduced downtime and lower operating costs for manufacturers. Furthermore, improvements in design modeling software are enabling engineers to simulate and optimize die performance before production, ensuring that new designs meet operational demands from the outset. As these trends continue to evolve, the punch die industry is poised for a revolutionary shift that promises to redefine manufacturing standards in the coming years.

The punch die industry is poised for significant growth in 2025, driven by innovations in manufacturing technologies and increasing demand from various sectors, including automotive, electronics, and construction. The introduction of advanced materials and precision engineering techniques has improved the performance and longevity of punch dies, allowing manufacturers to meet the rising standards of efficiency and quality. Automation in die production is also streamlining operations, reducing lead times, and minimizing costs, which can further elevate market growth.

Additionally, the push for sustainability is influencing the punch die market as companies seek to adopt eco-friendly practices. This includes the development of recyclable materials and energy-efficient manufacturing processes. As industries become more conscious of their environmental impact, the demand for sustainable punch die solutions is expected to rise. Furthermore, the integration of smart technologies and IoT in die design and maintenance is enhancing productivity and reducing downtime, positioning the punch die sector for robust expansion in the coming years. These trends signify a transformative period for the industry, highlighting both the opportunities and challenges that manufacturers will face in 2025.

The punch die manufacturing industry is on the brink of transformative innovations in 2025, driven by advancements in technology. One of the most significant developments is the integration of artificial intelligence into the design and production process. AI-driven simulations allow manufacturers to troubleshoot potential issues before the actual production, leading to higher efficiency and reduced waste. Additionally, machine learning algorithms can predict tool wear, optimizing maintenance schedules and extending the life of dies.

Another trend is the rise of additive manufacturing techniques like 3D printing for producing punch dies. This method enables more complex geometries that traditional processes cannot achieve, allowing for customization and faster prototyping. Moreover, the scalability of 3D printing reduces lead times, making it an appealing option for manufacturers looking to stay competitive in a rapidly evolving market.

Tip: To maximize the benefits of these technological advancements, ensure continuous training for your design and manufacturing teams. Staying updated with the latest tools and methodologies in punch die production will not only enhance your operational efficiency but also foster a culture of innovation within your organization. Embrace collaboration with technology firms to access cutting-edge solutions that can further streamline your processes.

The advent of Industry 4.0 is revolutionizing various manufacturing sectors, including punch die production. By integrating advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics into the production process, manufacturers can significantly enhance efficiency and quality. Real-time data collection from sensors on machinery allows for immediate feedback and adjustments, thus optimizing performance and reducing waste. Predictive maintenance, powered by AI algorithms, can identify potential failures before they occur, minimizing downtime and ensuring continuous operation.

Moreover, Industry 4.0 facilitates greater customization and flexibility in punch die production. With automated systems and smart factories, manufacturers can swiftly adapt to changing demands, producing intricate designs without compromising speed or reliability. The use of advanced simulation software aids in the design phase, enabling engineers to visualize and test their ideas in virtual environments to achieve superior results. Through these innovations, the punch die manufacturing sector stands to improve product quality while streamlining production processes, ultimately leading to higher customer satisfaction and competitive advantage in the marketplace.

As industries continue to evolve, the focus on sustainability in punch die design and material selection is becoming increasingly prominent. In 2025, manufacturers are expected to prioritize eco-friendly materials that not only enhance performance but also minimize environmental impact. This shift is driven by the need to reduce waste and energy consumption throughout the production process. Innovative materials such as bio-based composites and recycled metals are gaining traction, allowing for the production of durable punch dies that align with global sustainability goals.

Additionally, advancements in manufacturing technologies, such as additive manufacturing and precision machining, are enabling the creation of customized punch dies that are lighter and more efficient. These techniques allow for complex geometries that require less material without compromising strength and effectiveness. By integrating sustainable practices into the design phase, companies can significantly reduce their carbon footprint and contribute to a circular economy, where resources are reused and repurposed.

Overall, the trends in punch die design reflect a broader industry movement towards sustainability, with material selection playing a crucial role. As innovations continue to emerge, the challenge remains for manufacturers to balance performance demands with eco-friendly practices, ultimately paving the way for a more sustainable future in production.

The article "Understanding Punch Die: Top Trends and Innovations in 2025" explores the projected growth and transformative changes within the punch die industry. It highlights market growth driven by advances in manufacturing processes and the integration of Industry 4.0 technologies, enhancing production efficiency and product quality. Significant technological advancements are poised to reshape how punch dies are designed and fabricated, allowing for greater precision and customization.

Additionally, the article discusses the increasing focus on sustainability in punch die design and material selection, as manufacturers seek eco-friendly alternatives without compromising performance. Emerging applications of punch die across diverse sectors reveal its expanding relevance, showcasing the versatility and innovation within the industry as it adapts to evolving market needs.