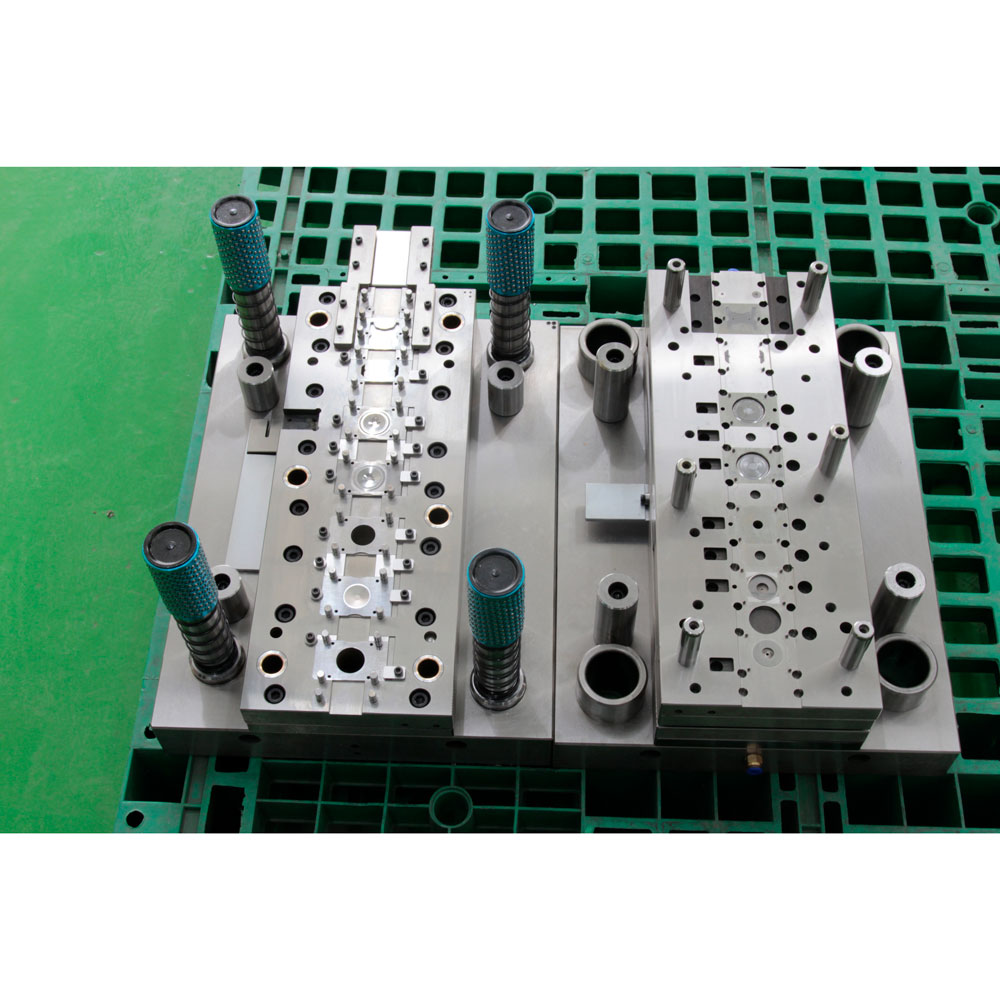

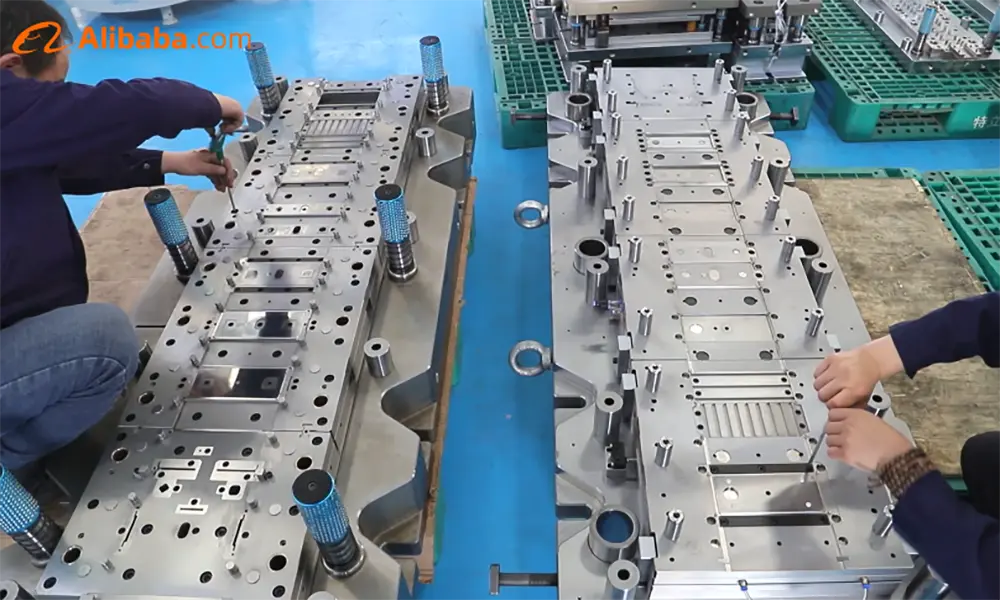

While ensuring efficient production, the mold also greatly improves the safety and stability of the production process. The innovative flip function makes the mold operation easier, requiring only a small amount of manual intervention, which will greatly reduce the labor intensity of operators and reduce the error rate. In addition, the mold design fully considers the discharge and heat dissipation issues to ensure smooth and efficient operation of each step, reduce equipment wear and failure rate, and improve overall production efficiency.

SDD flip-flop moulds are widely used in the production of various types of batteries, whether cylindrical, square or special-shaped battery shells, they can handle them easily. Through continuous technological innovation and optimization, our moulds can adapt to metal sheets of different thicknesses and materials, greatly expanding the scope of application of the product.

In general, choosing our SDD flip-flop mould is not only choosing a high-quality production tool, but also adding an efficient and stable guarantee to your production line. We are committed to providing customers with the highest standard of products and services, continuously promoting the advancement of battery manufacturing technology, and looking forward to creating a brilliant future with you.