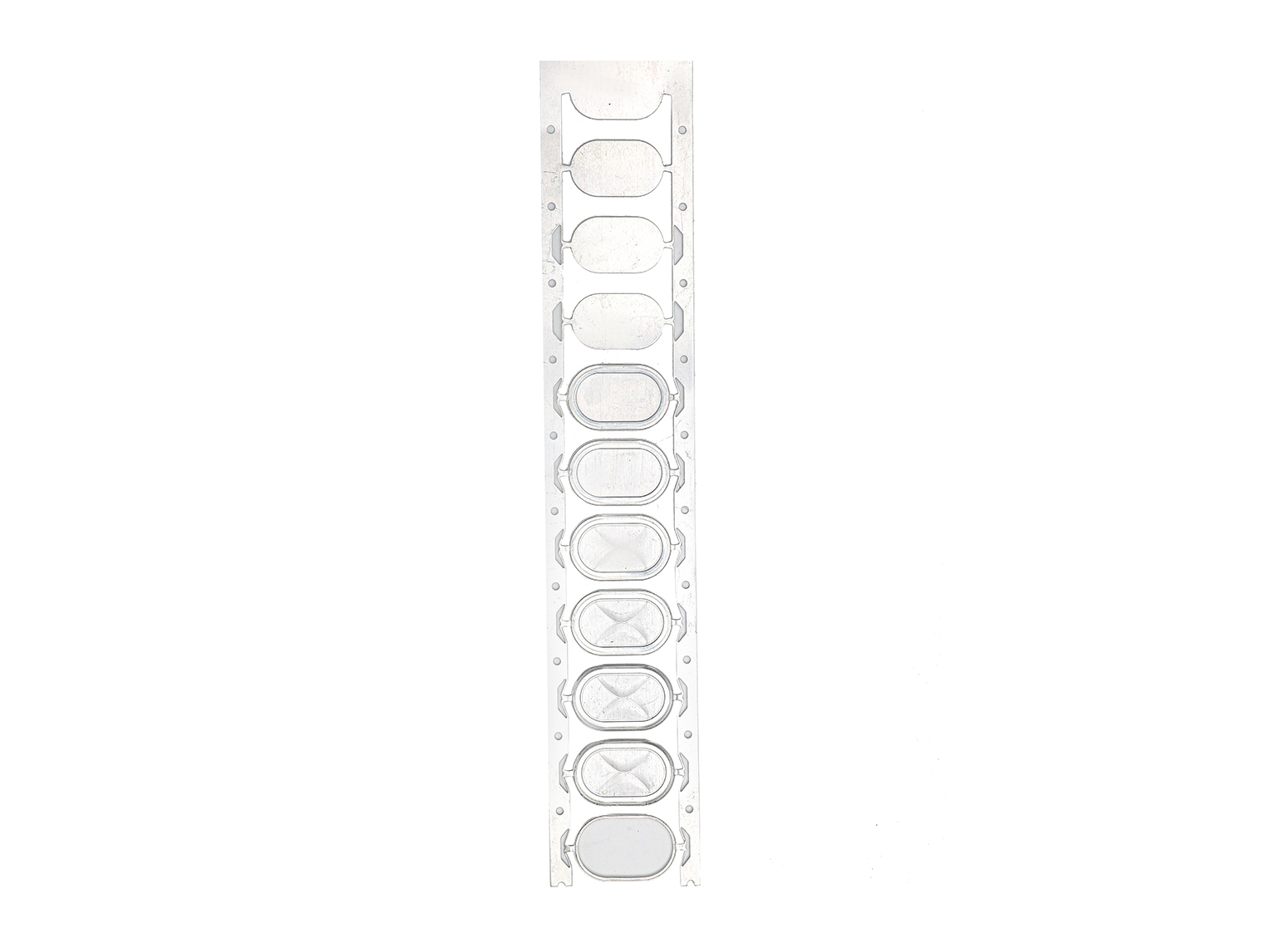

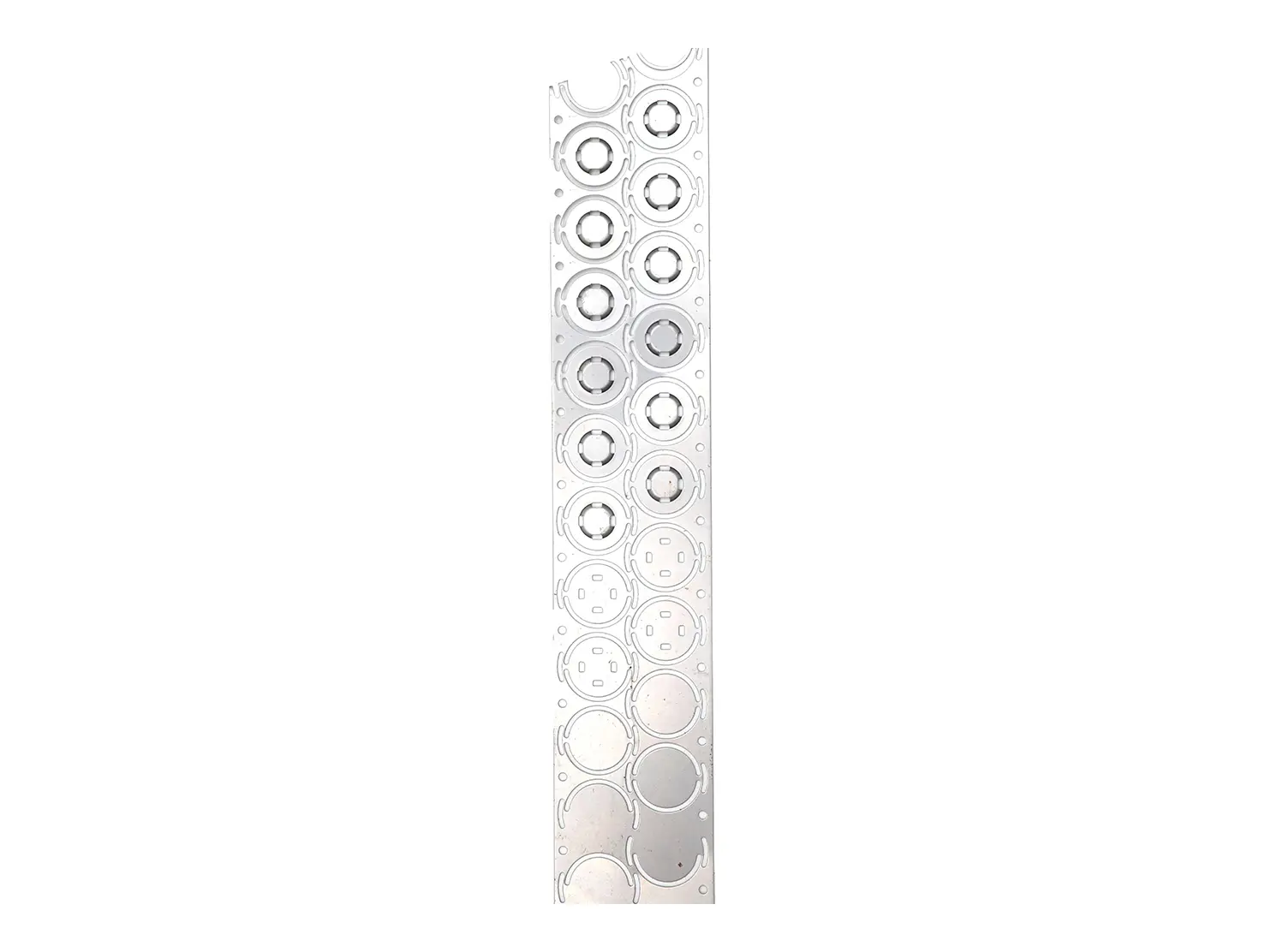

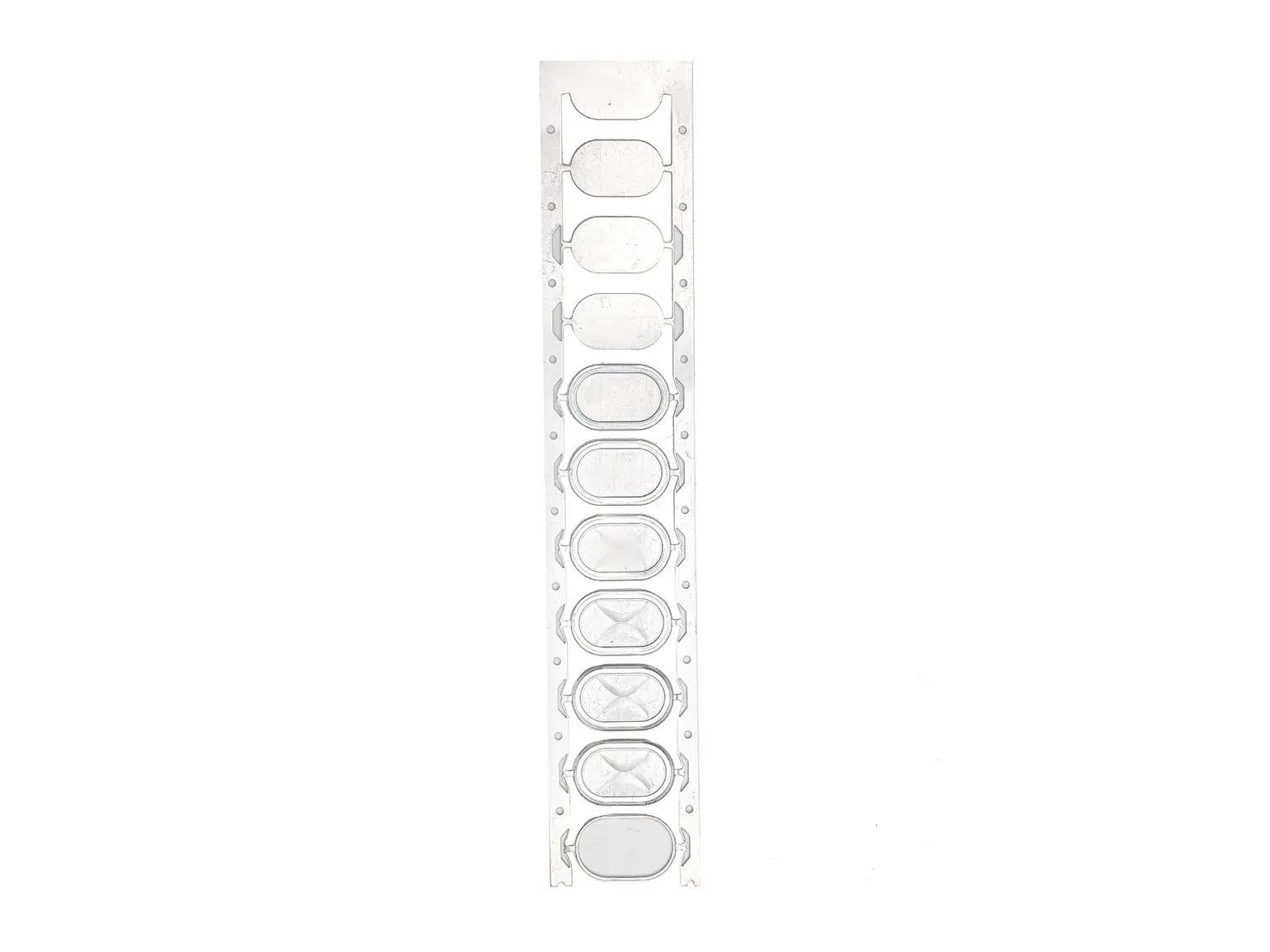

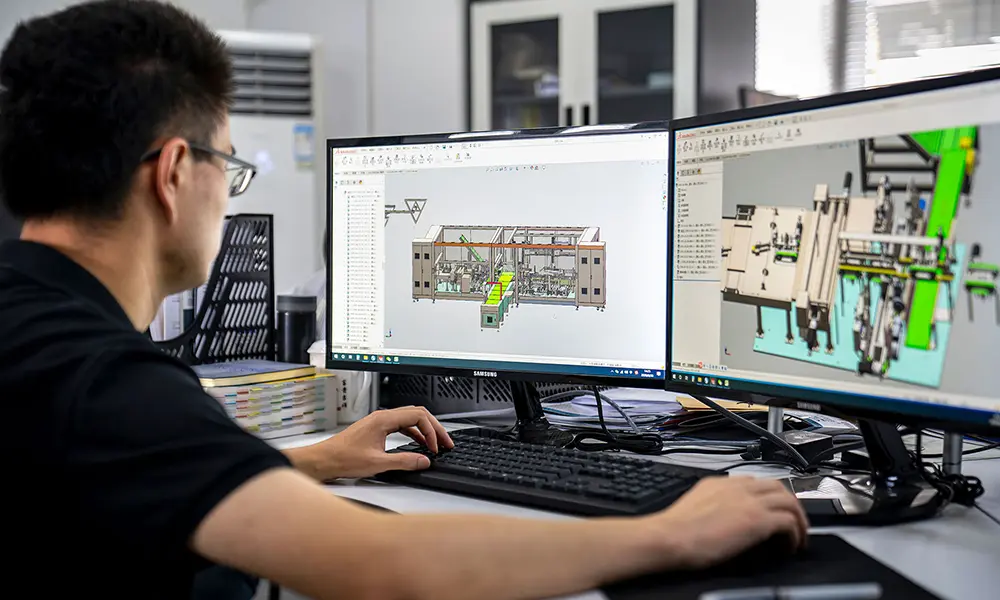

1. Personalised design: Whether it is complex geometric shapes, special size requirements, or unique surface treatment, we can accurately realise and create unique products for you.

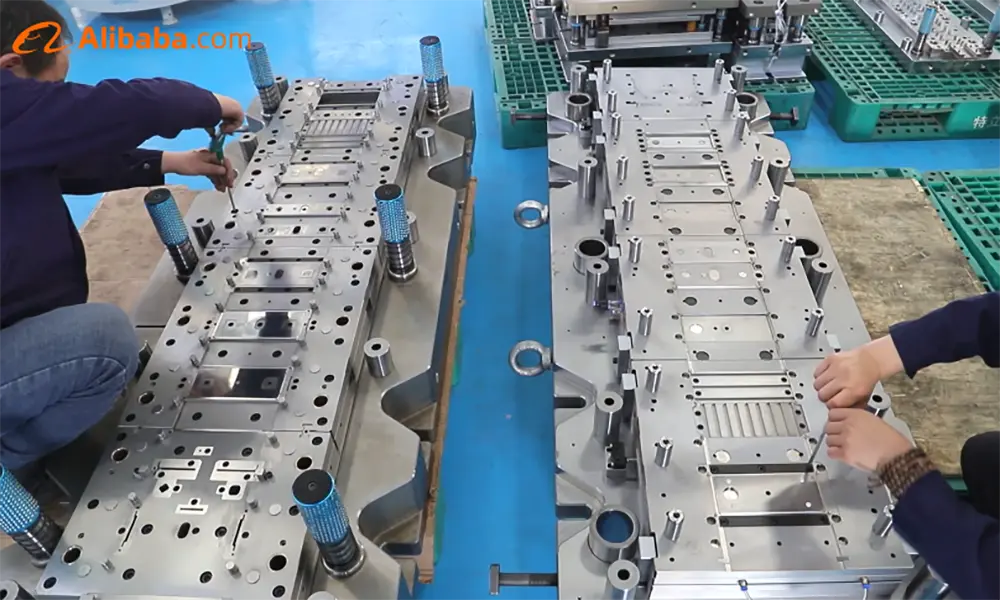

2. Variety of materials: we can process a variety of metal materials, such as stainless steel, aluminium alloy, copper, etc., as well as some non-metallic materials. According to your product performance requirements and cost considerations, we recommend the most suitable materials for you to ensure the quality and cost-effectiveness of stamped parts.

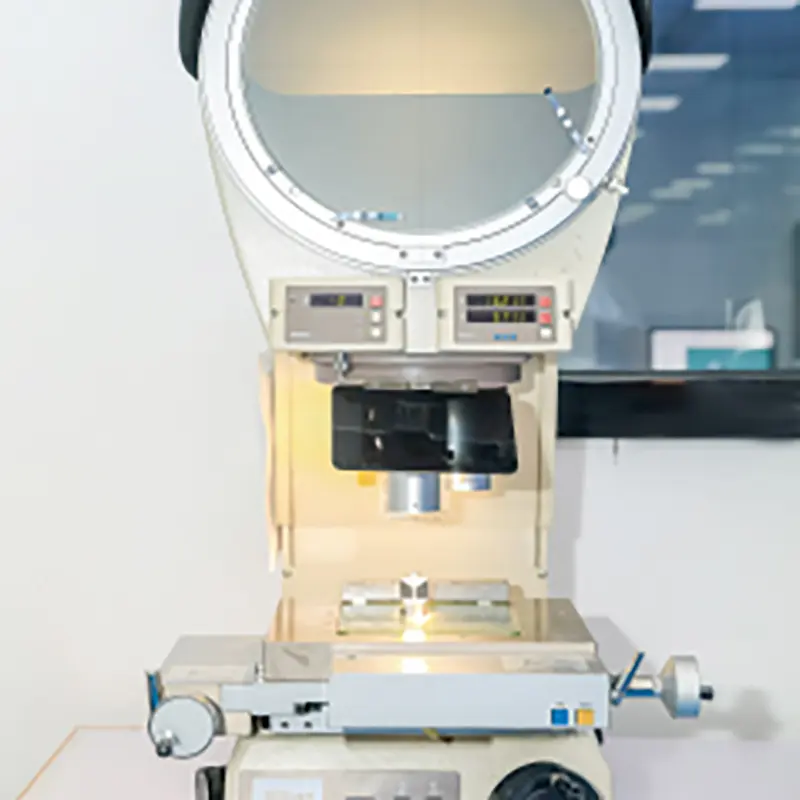

3. Strict quality control: We always put quality in the first place and carry out strict quality inspection at every step from raw material procurement to production and processing. We adopt advanced testing equipment and methods to ensure that the dimensional accuracy, surface quality and mechanical properties of the stamped parts meet your requirements.

4. Efficient production: with advanced production equipment and optimised production processes, we are able to achieve efficient customised processing of stamped parts. Whether you are a small batch custom or mass production, we can deliver on time and meet your project schedule.

5. Beautiful appearance, the surface of the stamping processed products is smooth, to meet the aesthetic requirements of high-end products.